A method for comprehensive utilization of boron and iron tailings from boron and mafia ore

A technology of mafic ore and iron tailings, which is applied in the field of comprehensive utilization of secondary resources, can solve problems such as environmental pollution and waste of resources, achieve high purity, realize zero discharge of solid waste, and reduce apparent porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

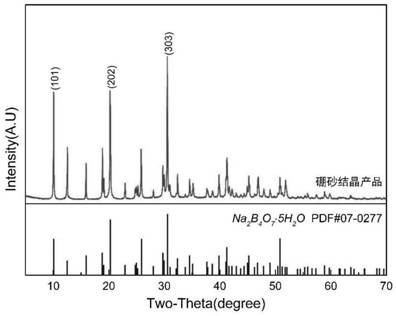

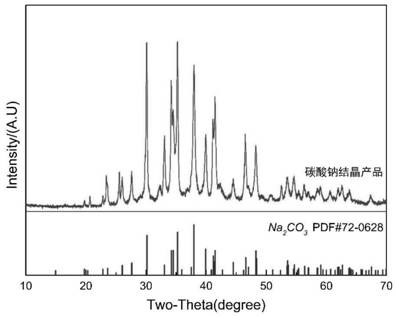

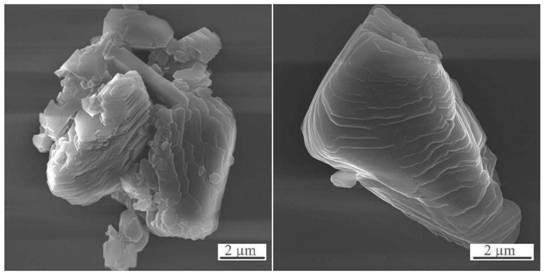

[0035] Example 1: Using the above-mentioned tailings as raw materials, according to the liquid-solid mass ratio of 6:1, the water leaching temperature is 180°C, and the water leaching time is 6h, after leaching, the leaching solution and the leaching residue are obtained by filtration. Pour CO into the leachate 2The gas and the leaching solution are evaporated and concentrated to separate crystals of borax and sodium carbonate. The leaching slag is pressed and formed under the pressure of 100-150MPa, and then dried; after the treatment, it is calcined in an oxidizing atmosphere at 1300-1350° C. for 2-3 hours to obtain a magnesia refractory material.

[0036] In Example 1, the leaching rates of boron and sodium in the leaching process were 95.69% and 95.41%, respectively. The refractoriness of the refractory prepared from the leaching slag is 1600℃~1650℃, and the bulk density and apparent porosity are 1.48g / cm, respectively. 3 , 1.88%.

[0037] Pour CO into the leachate 2 g...

Embodiment 2

[0038] Example 2: Using the above-mentioned tailings as raw materials, according to the liquid-solid mass ratio of 8:1, the water leaching temperature of 180 ° C, and the water leaching time of 6 hours, after leaching, the leaching solution and the leaching slag were obtained by filtration. Pour CO into the leachate 2 The gas and the leaching solution are evaporated and concentrated to separate crystals of borax and sodium carbonate. The leaching slag is pressed and formed under the pressure of 100-150MPa, and then dried; after the treatment, it is calcined in an oxidizing atmosphere at 1300-1350° C. for 2-3 hours to obtain a magnesia refractory material.

[0039] In Example 2, the leaching rates of boron and sodium in the leaching process were 96.47% and 95.94%. The refractoriness of the refractory prepared from the leaching slag is 1610℃~1670℃, and the bulk density and apparent porosity are 1.49g / cm, respectively. 3 , 1.85%.

[0040] Pour CO into the leachate 2 gas, the ...

Embodiment 3

[0041] Example 3: Using the above-mentioned tailings as raw materials, according to the liquid-solid mass ratio of 8:1, the water leaching temperature of 180 ° C, and the water leaching time of 5 hours, after leaching, the leaching solution and the leaching slag were obtained by filtration. Pour CO into the leachate 2 The gas and the leaching solution are evaporated and concentrated to separate crystals of borax and sodium carbonate. The leaching slag is pressed and formed under the pressure of 100-150MPa, and then dried; after the treatment, it is calcined in an oxidizing atmosphere at 1300-1350° C. for 2-3 hours to obtain a magnesia refractory material.

[0042] In Example 3, the leaching rates of boron and sodium in the leaching process were 96.69% and 96.41%. The refractoriness of the refractory prepared from the leaching slag is 1630℃~1680℃, and the bulk density and apparent porosity are respectively 1.49g / cm 3 , 2.105%.

[0043] Pour CO into the leachate 2 gas, the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com