An anode furnace refining equipment

A technology of refining equipment and anode furnace, applied in the field of anode furnace refining equipment, to achieve the effect of reducing burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

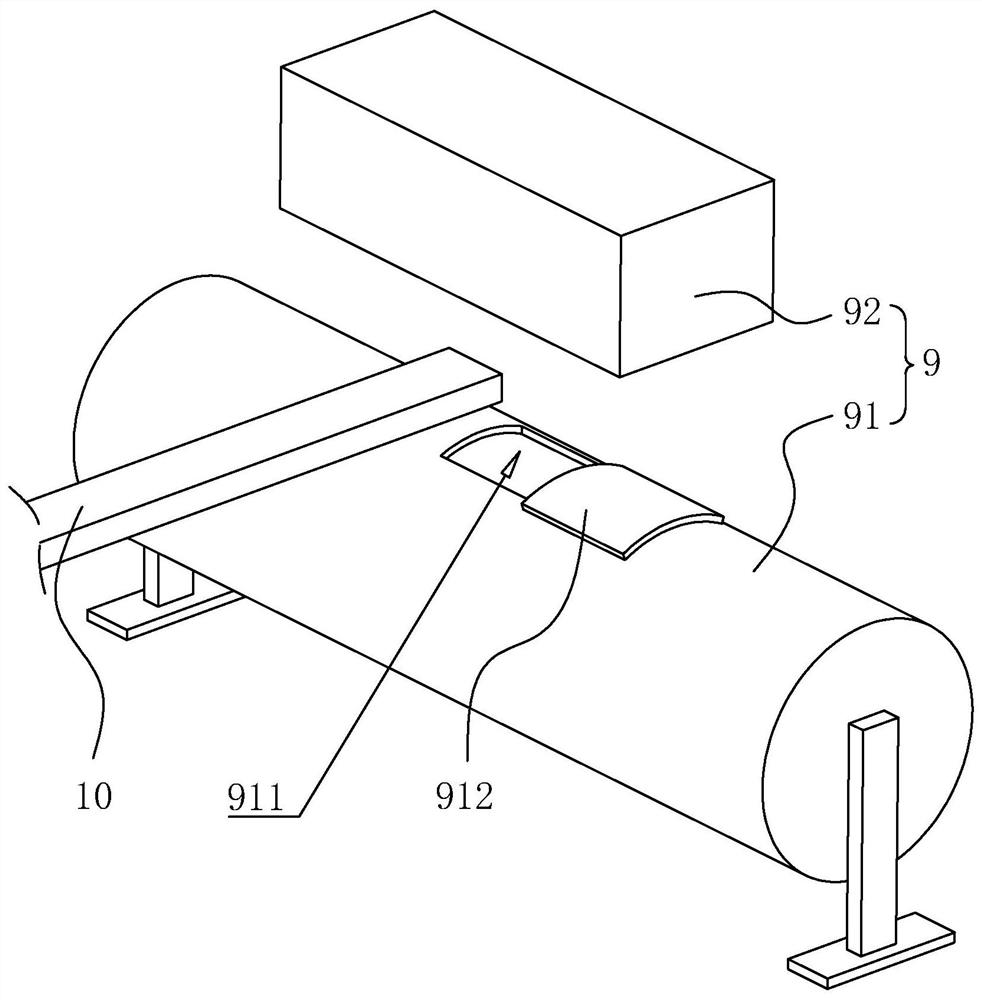

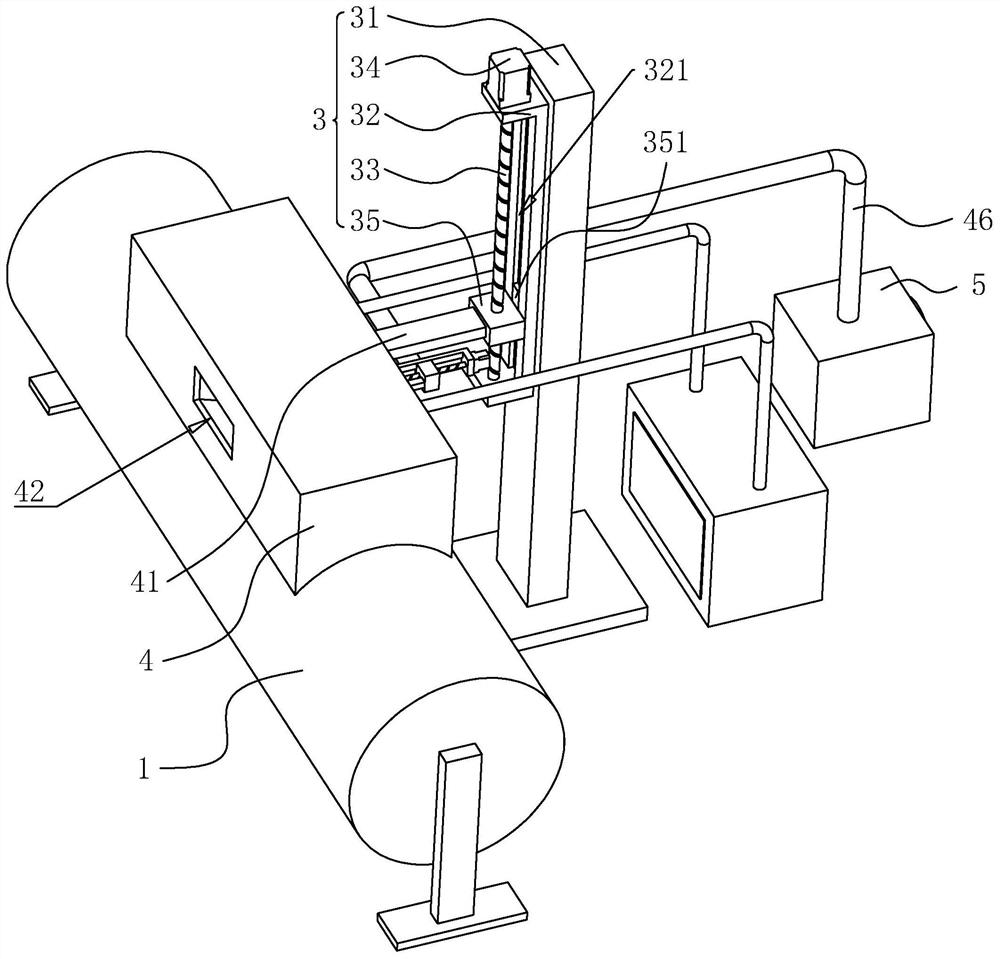

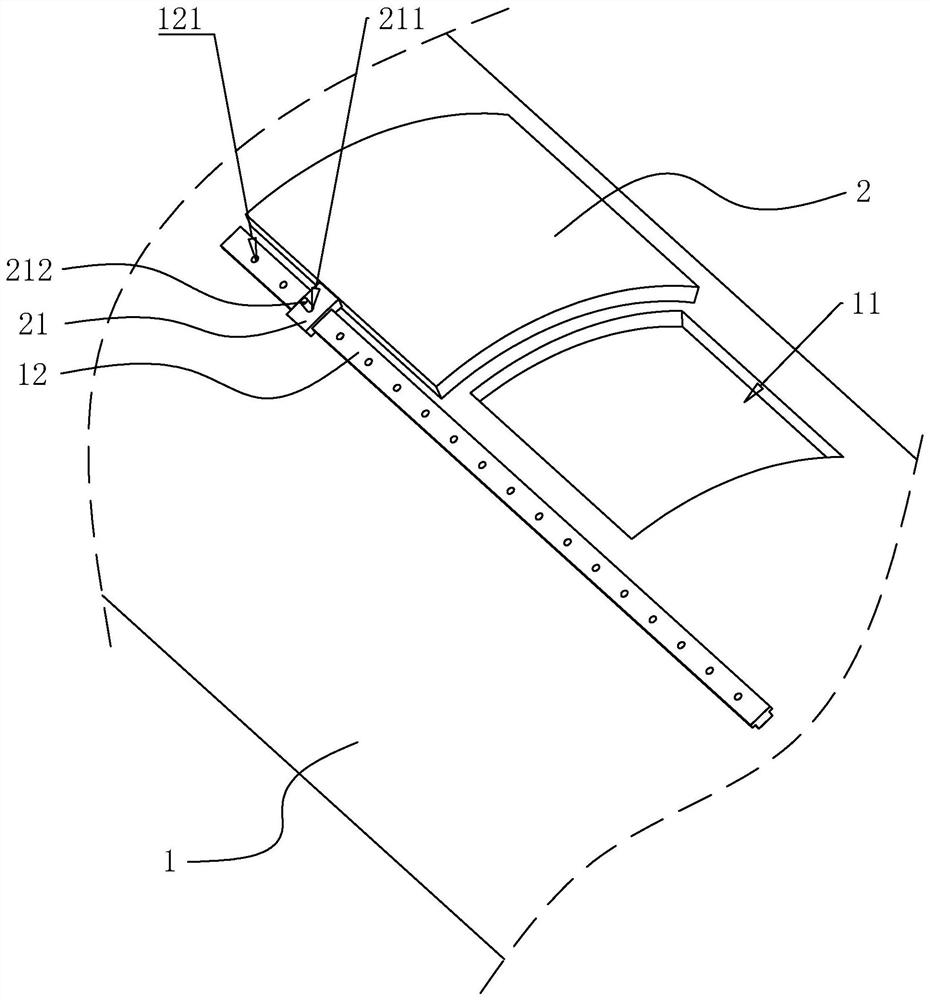

[0042] refer to figure 2 and image 3 , a kind of anode furnace refining equipment includes a furnace body 1, a protective cover 2, a driving assembly 3, a windshield 4 and a flue gas treatment part 5, referring to Figure 4 , also includes the flue gas rectification assembly 6.

[0043] refer to figure 2 and image 3 , the top of the furnace body 1 is provided with a feed inlet 11, and the protective cover 2 is detachably located at the feed inlet 11. The outer wall of the furnace body 1 is fixedly connected with a slide rail 12 along the length direction parallel to the furnace body 1, and the slide rail 12 is connected to the furnace body. The body 1 is fixedly connected by screws, and the side wall of the protective cover 2 is welded with a slider 21. In this embodiment, the slide rail 12 is a T-shaped slide rail, and the slider 21 is a T-shaped slider. The slider 21 is along the length direction of the slide rail 12. It is slidingly connected with the slide rail 12; t...

Embodiment 2

[0057] refer to Figure 7 , The difference between this embodiment and Embodiment 1 is that the pusher assembly 83 is different. In this embodiment, the pusher assembly 83 is a linear motor, and the pusher assembly 83 includes a guide table 835 and a bearing slide 836; the load slide 836 Slidingly connected with the guide platform 835 along the sliding direction of the cooling net 71, the guide platform 835 is fixedly connected with the windshield 4 by screws, and the carrying slide 836 is fixedly connected with the adapter rod 8342 by screws.

[0058] The implementation principle of Embodiment 2 is: when the adapter rod 8342 is driven to move, the guide table 835 drives the carrying slide 836 to move, and the carrying slide 836 drives the transfer rod 8342 to move synchronously during the movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com