A production method of 590mpa grade enhanced formability hot-dip galvanized dual-phase steel

A production method, the technology of dual-phase steel, applied in the field of steel rolling, can solve the problems that are not suitable for mass production in factories, achieve uniform color and no defects, improve the adhesion of zinc layer, good elongation and work hardening characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

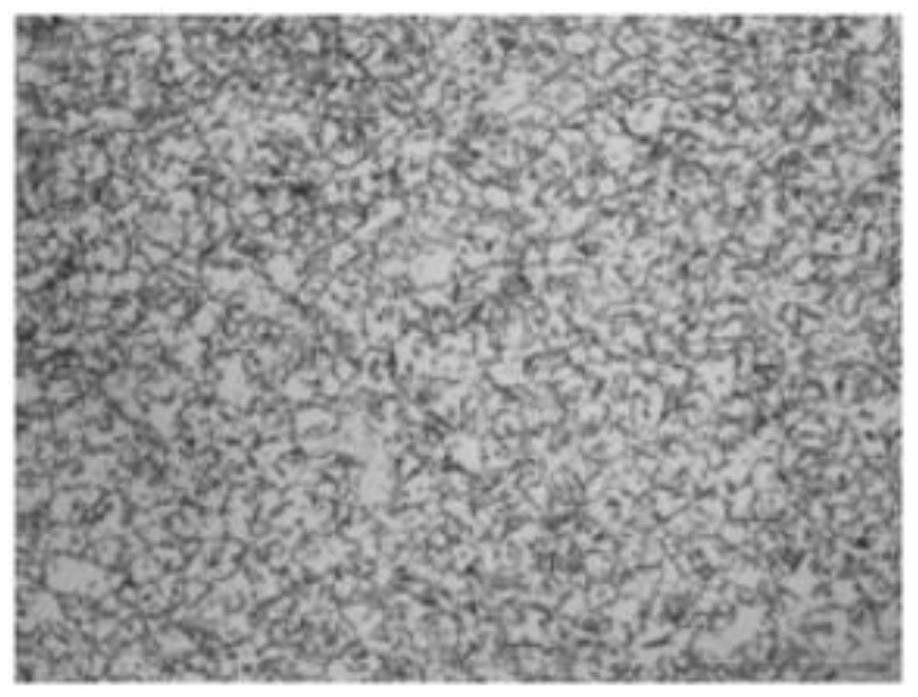

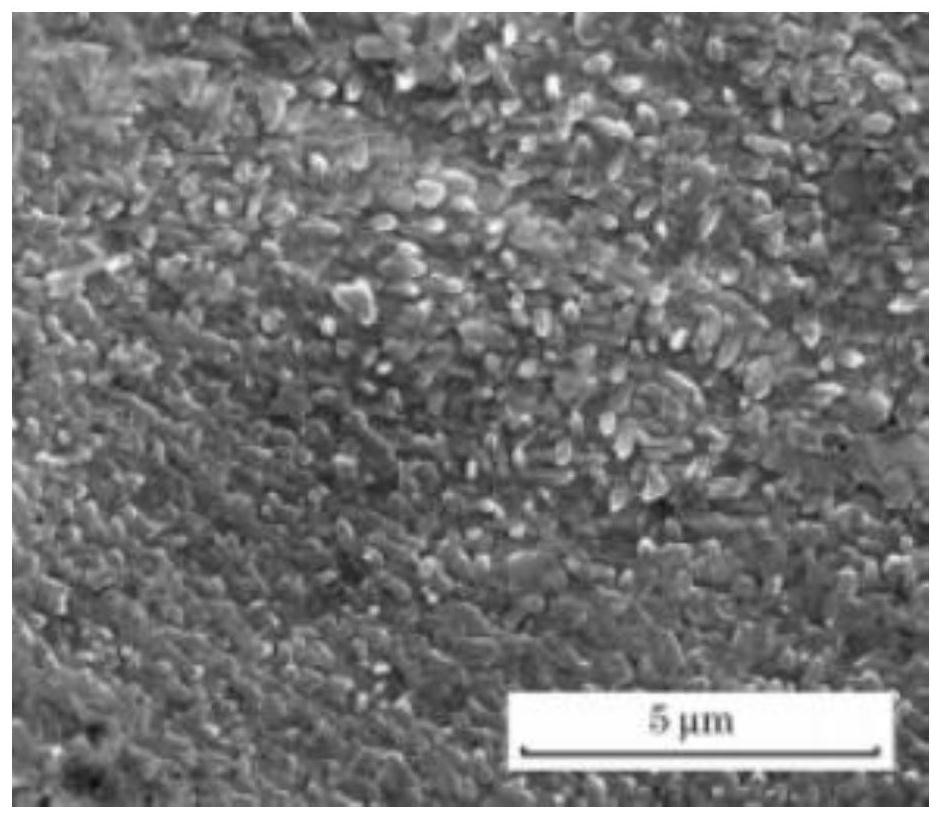

Image

Examples

Embodiment Construction

[0039] The following are specific examples of the present invention, further describing the technical solutions of the present invention, but the protection scope of the present invention is not limited to these examples. All changes or equivalent substitutions that do not depart from the concept of the present invention are included in the protection scope of the present invention.

[0040] A 590MPa grade enhanced formability hot-dip galvanized dual-phase steel and its production method in the embodiment of the present invention comprise the following steps:

[0041] 1) Melt molten steel is smelted, and high-aluminum steel mold slag and continuous casting method are used to cast continuous casting slabs; the continuous casting process is protected by blowing argon to avoid oxidation of molten steel; medium carbon covering agent is used to avoid exposure of molten steel, and the secondary cooling water is distributed according to the model Mode, choose high aluminum steel mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com