8-shaped CT lock catch steel pipe pile and Larsen steel sheet pile combined cofferdam structure

A technology of Larsen steel sheet piles and locking steel pipes, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of large construction area occupied, short construction period, and difficult construction, so as to improve strength and save construction cost, the effect of strengthening the protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

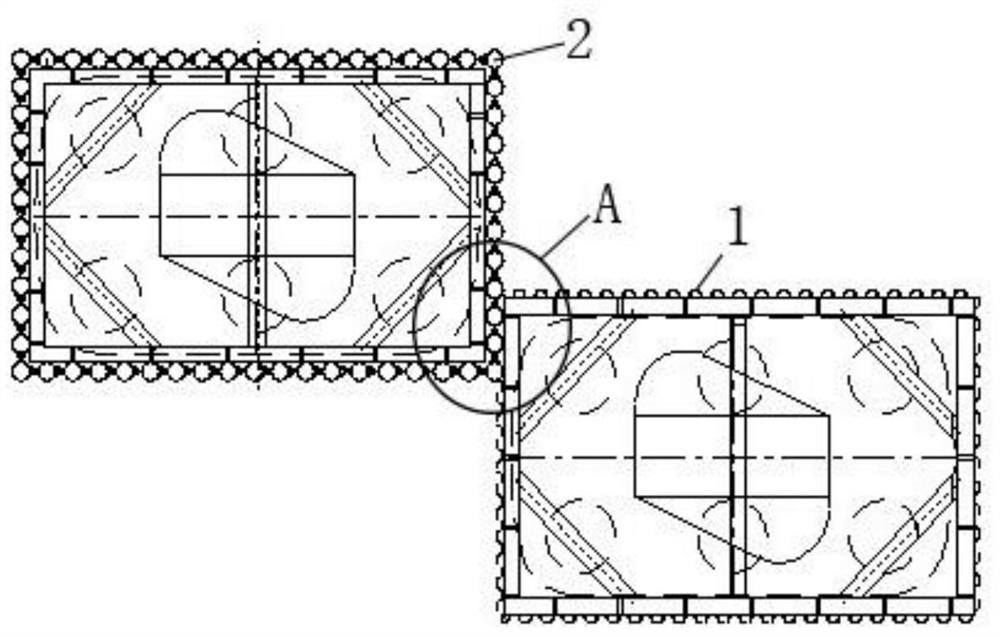

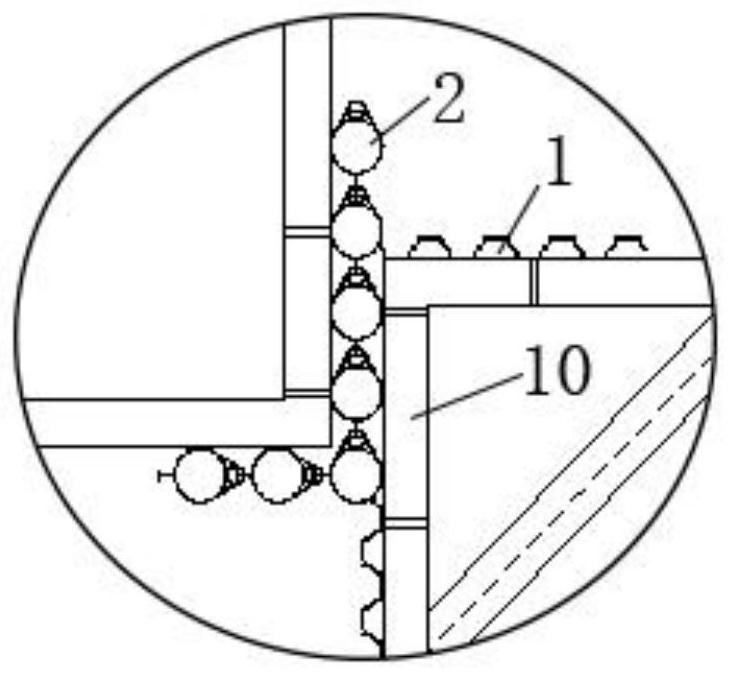

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

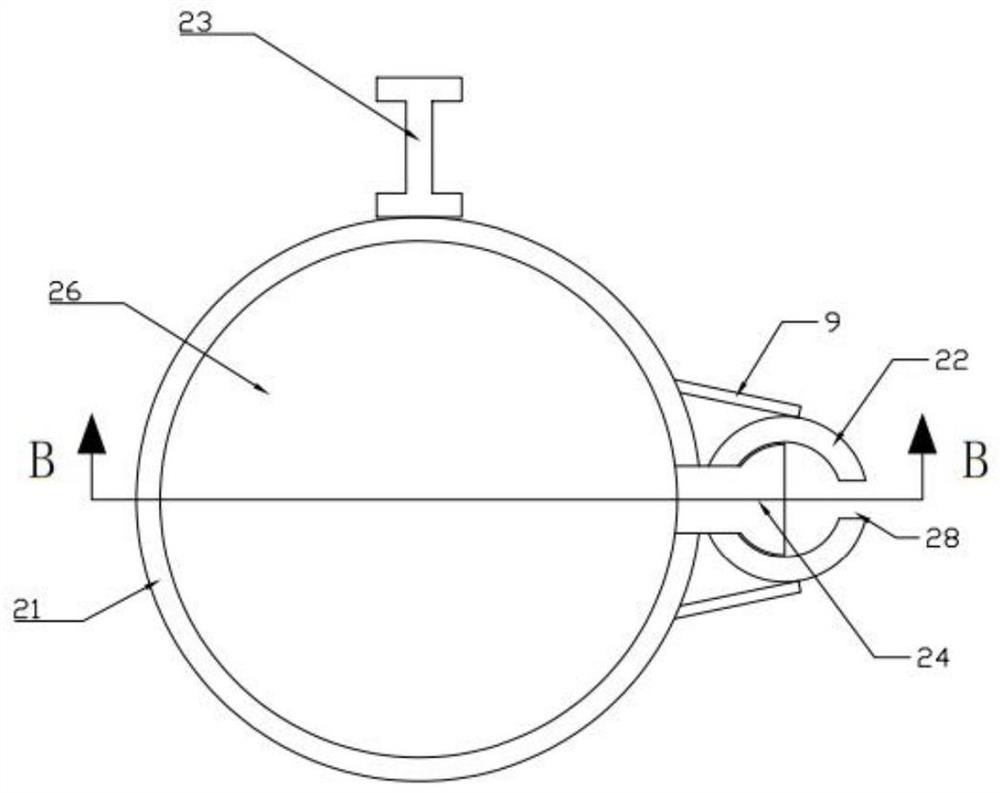

[0023] Such as Figure 1-5 As shown, the embodiment provides an 8-shaped CT locking steel pipe pile and Larsen steel sheet pile combined cofferdam structure, including Larsen steel sheet pile 1 and CT locking steel pipe pile 2, CT locking steel pipe pile 2 Including the first steel pipe 21, the second steel pipe 22, the I-beam 23, the connecting rod 24, the rotating shaft 25, the cover plate 26 and the turning block 27, the outer side of the first steel pipe 21 is welded with the I-beam 23, and the turning block 27 is rotatably arranged on In the first steel pipe 21, one end of the rotating shaft 25 is welded to the top of the rotating block 27, the other end of the rotating shaft 25 is welded with a cover plate 26, the connecting rod 24 is welded to the inner wall of the second steel pipe 22, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com