Large-span vestibule truss integral transportation method

A technology of integral transportation and corridor truss, applied in construction, building structure, processing of building materials, etc., can solve the problems of high cost, high difficulty, parts occupying construction site, etc., to avoid long-term circuit breakage, economic loss, cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

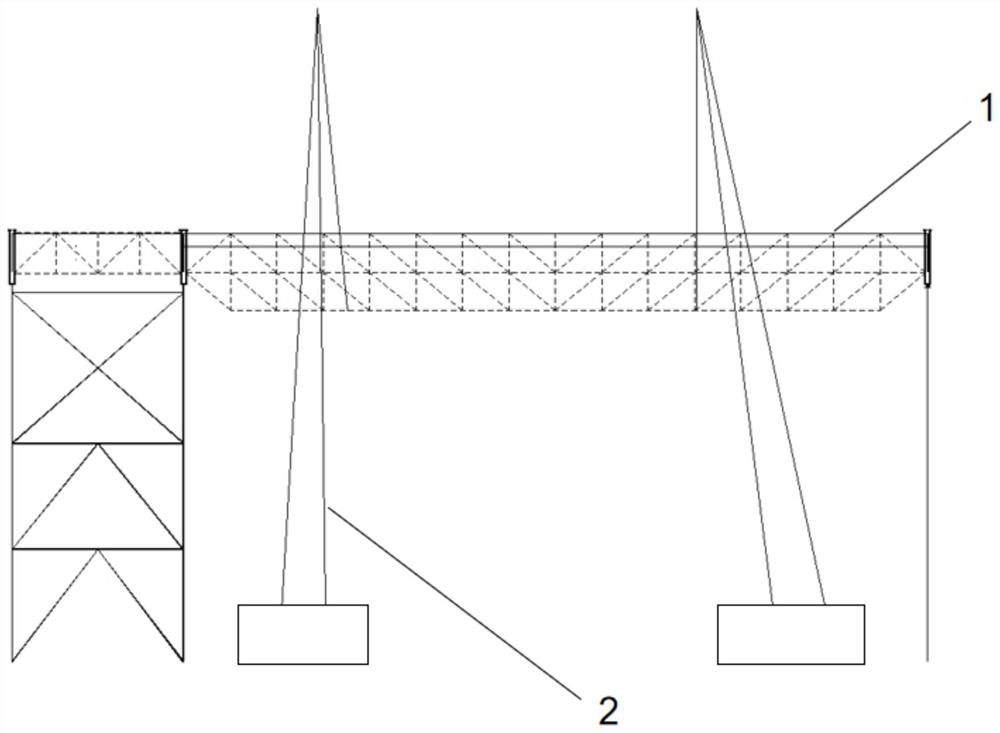

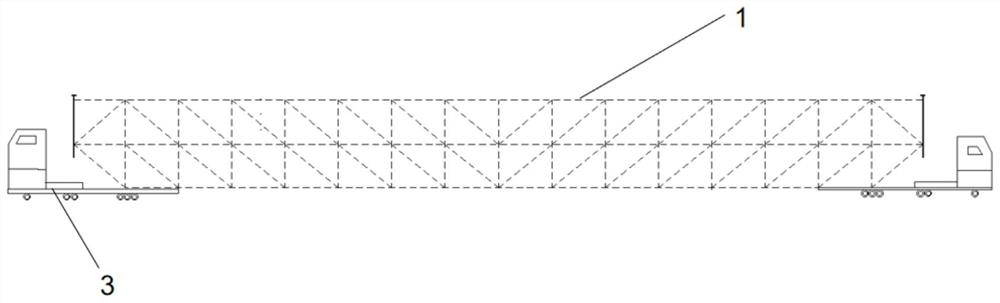

[0040] Such as Figure 1-2 As shown, a schematic diagram of hoisting and transportation in a large-span corridor truss overall transportation method is shown, including a corridor truss 1 , a crawler crane 2 , and a pallet truck 3 . The overall transportation method of the corridor truss is briefly summarized as the following steps:

[0041] S1. Selection of assembly site, choose a site suitable for assembly;

[0042] S2, assembling, assembling corridor trusses;

[0043] S3. Hoisting. Use a crawler crane to lift the corridor truss assembled in step S2 off the ground, and reverse the two trolleys back and forth to under the corridor truss, so that the portal frame of the corridor truss is located lowered onto the cart;

[0044] S4, transportation, two pallet trucks start at the same time, one moves forward and the other retreats, and transports the corridor truss to the hoisting position;

[0045] S5. Unloading: use a crawler crane to unload the corridor truss, hoist the co...

Embodiment 2

[0051] Construction environment and requirements: The engineering project of the entire blast furnace feeding and returning system is mainly composed of corridor structure and commissioner's station. The corridor along the Weisan section of the road in the factory area is a sinter corridor and a blast furnace return corridor. The average length of the corridor is 24m, of which two sections are 60m long.

[0052] Adopt the traditional method: first transport the scattered components to the hoisting area for assembly. The assembly time is 10 days, and the hoisting is 2 days. It is necessary to close the Weisan Road and Jinger Road in the factory area for 15 days. According to the evaluation of the owner, if the road is closed for 15 days, it will affect production. , a loss of about 6 million.

[0053] Using the method provided in Example 1: put the assembly site at a position about 800m away from the hoisting position and assemble it into a whole, and then transport it to the h...

Embodiment 3

[0056] Construction environment and requirements: The corridor passes through Weisan Road. The length of the corridor is 47m, the height is 7.5m, and the weight is 220 tons.

[0057] Adopt the method of Example 1 for construction and transportation, overcome the impact of narrow site and road blockage, save 100,000 yuan for two shifts of special vehicles, and reduce the production loss of 2.8 million yuan.

[0058] In summary, the method of the present invention has the following advantages: 1. The 17.5m pallet truck belongs to a commonly used transport vehicle, which is convenient to rent, and the rental price is cheap, while the rental cost of special low-board vehicles used in the prior art is high, and it is not easy Find the vehicle source, and the manufacturer is unwilling to rent short-term; 2. The floor of the 17.5m pallet truck is high and limited by the terrain, while the distance between the floor and the ground of the special low-board vehicle required by the existi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com