Mounting and dismounting mechanism for cross arms of pole-mounted transformer and using method

A pole-mounted transformer and cross-arm technology, which is applied in the field of pole-mounted transformer cross-arm installation and disassembly mechanism, can solve the problems of difficult operation, long time-consuming, time-consuming and labor-intensive, etc., and achieve the effect of reducing labor and preventing wedge limit failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be understood that these descriptions are exemplary only, and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

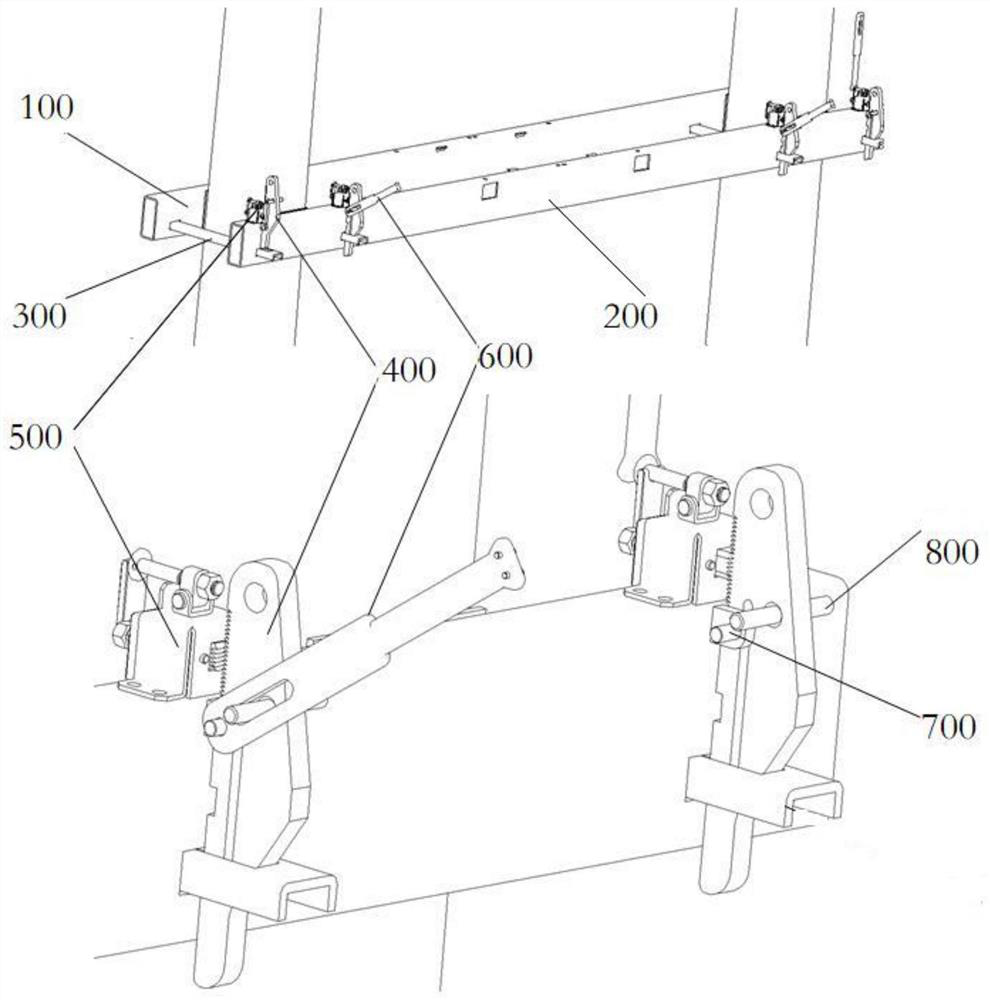

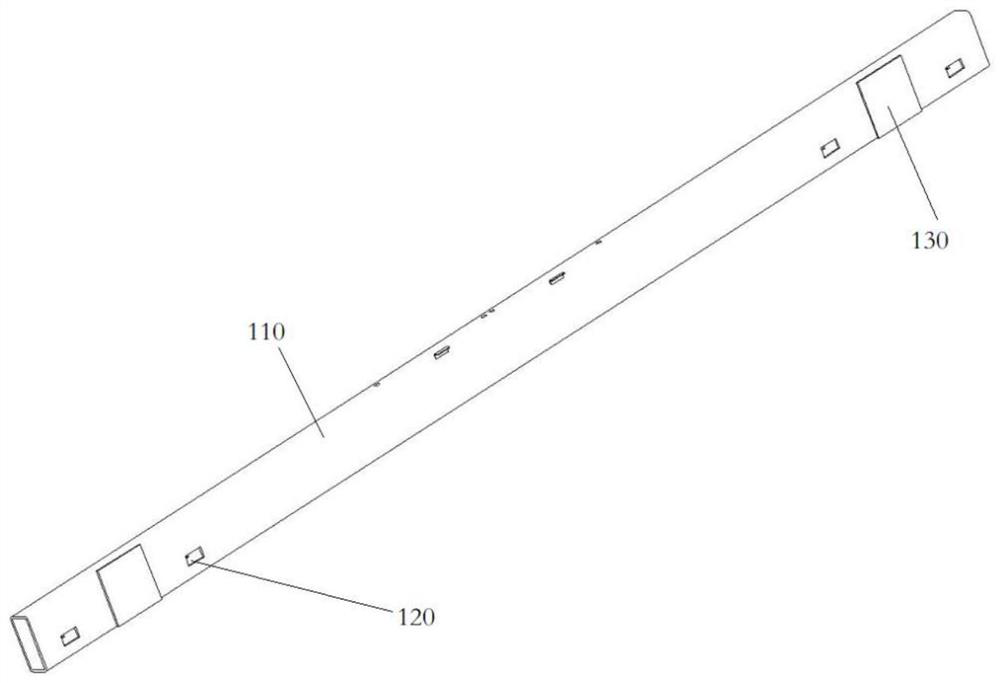

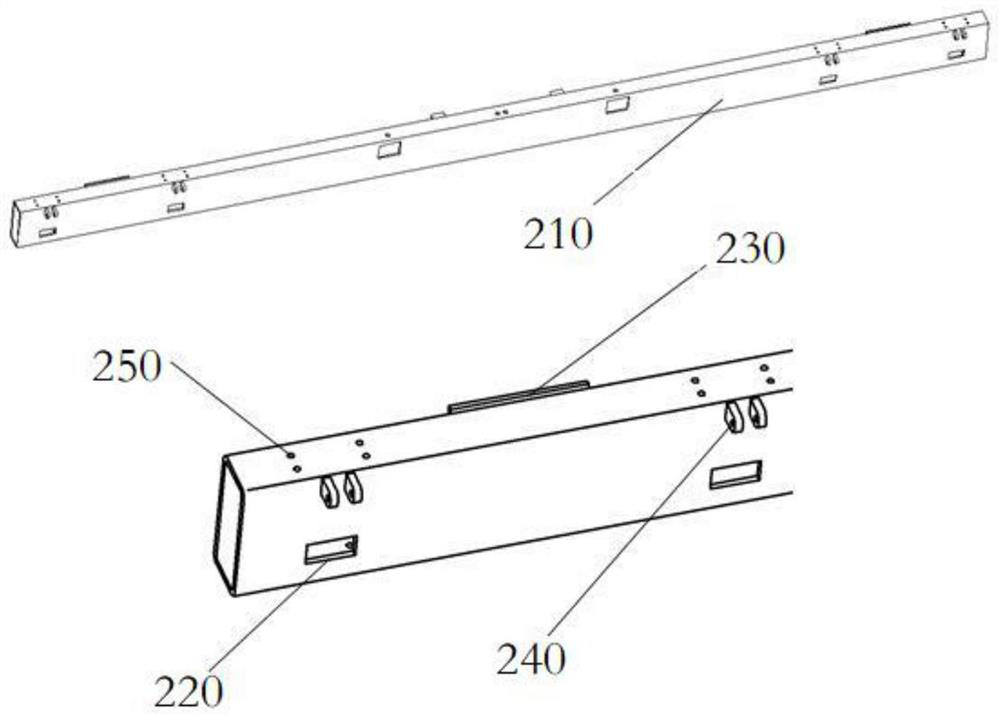

[0048] The invention relates to a bolt-free fast installation and quick disassembly mechanism for supporting cross-arms of 10kV level 400kVA and below capacity oil-immersed transformers on utility poles, such as Figure 1 to Figure 8 As shown, the pole-mounted transformer cross-arm of the present invention has a bolt-free quick installation and disassembly mechanism comprising two cross-arms (the first cross-arm 100 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com