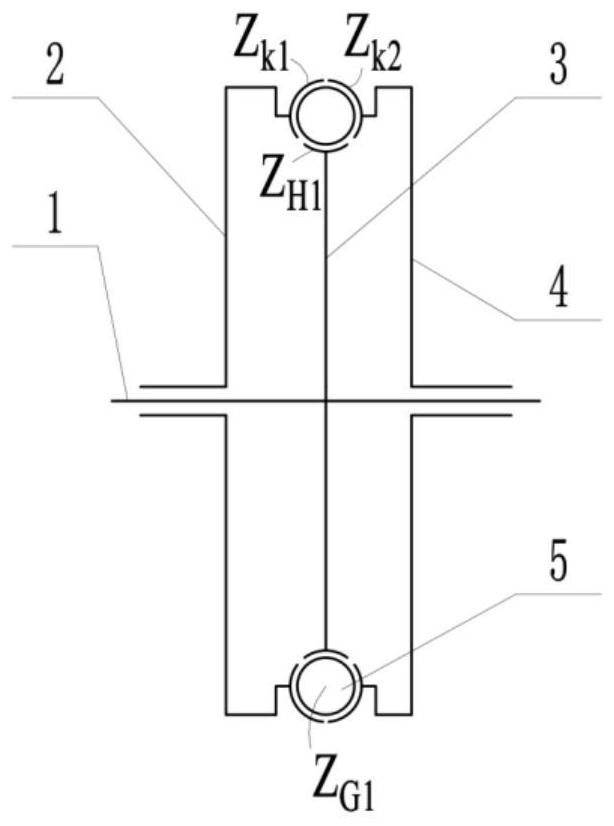

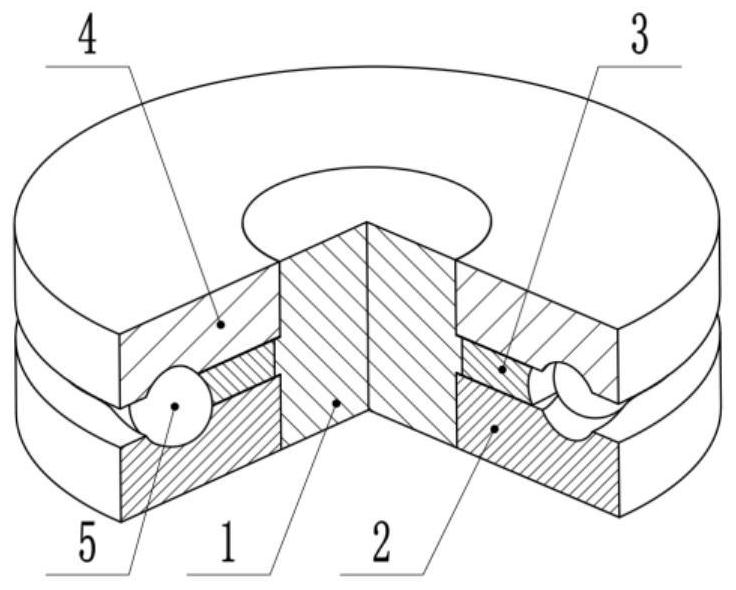

Three-string oscillating tooth transmission mechanism and speed reducer thereof

A three-string movable tooth and transmission mechanism technology, which is applied in the field of movable tooth transmission, can solve complex problems and achieve the effect of simple processing and manufacturing, high bearing capacity and few parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0092] In the second embodiment, the movable tooth 10 and the movable tooth 15 both adopt steel balls with a diameter of 10 mm.

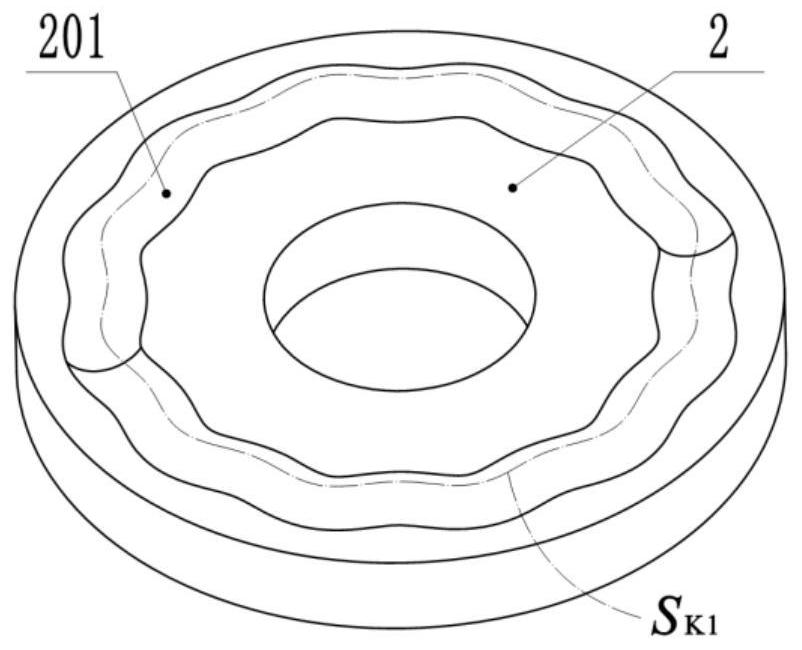

[0093] Figure 10 Among them, the tooth profile centerline S corresponding to the primary tuning line raceway 701 in the second embodiment K1 The plane Cartesian coordinate parametric equation of is:

[0094]

[0095] Figure 11 Among them, the tooth profile centerline S corresponding to the primary shock chord line raceway 801 in the second embodiment H1 The plane Cartesian coordinate parametric equation of is:

[0096]

[0097] Figure 12 Among them, the tooth profile centerline S corresponding to the first-stage moving string raceway 901 in the second embodiment K2 The plane Cartesian coordinate parametric equation of is:

[0098]

[0099] It can be known from the above expression that the primary shock string raceway 801 (or S H1 ) wave number is 2, and the number of first-level movable teeth 10 is 14, then the first-level tuning...

Embodiment 1

[0107] Embodiment 1 and Embodiment 2 respectively provide the schematic diagram of the single-stage three-chord movable tooth transmission mechanism and the two-stage serial three-chord movable tooth transmission mechanism, the structural diagram of the transmission unit and the structural diagram of the parts with string raceways in the transmission unit , so in the subsequent embodiments of the single-stage or double-stage three-chord movable tooth transmission mechanism, only a schematic diagram of the mechanism and a diagram of the transmission unit can be provided to illustrate the structure, and there is no need to provide a structural diagram of the parts with string raceways.

[0108] Figure 16 and Figure 17 It is the third embodiment of the present invention, which is a two-stage parallel three-chord movable tooth transmission mechanism, wherein, Figure 16 The schematic diagram of the two-stage parallel three-chord movable tooth transmission mechanism is given, ...

Embodiment 3

[0109] In the third embodiment, the movable tooth 10 adopts a steel ball with a diameter of 10 mm, and the movable tooth 15 adopts a steel ball with a diameter of 9 mm.

[0110] The tooth profile centerline S corresponding to the primary tuning line raceway 701 of the third embodiment K1 The plane Cartesian coordinate parametric equation of is:

[0111]

[0112] The centerline S of the tooth profile corresponding to the primary shock chord line raceway 801 in the third embodiment H1 The plane Cartesian coordinate parametric equation of is:

[0113]

[0114] The centerline S of the tooth profile corresponding to the primary moving string raceway 901 of the third embodiment K2 The plane Cartesian coordinate parametric equation of is:

[0115]

[0116] It can be seen from the above expression that the primary shock string raceway 801 (or S H1 ) wave number is 2, and the number of first-level movable teeth 10 is 14, then the first-level tuning wire raceway 701 (or S ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com