Tuned liquid damper design method, apparatus, medium and equipment

A technology for tuning liquid damping and design methods, applied in design optimization/simulation, geometric CAD, special data processing applications, etc., can solve problems such as inaccurate evaluation of TLD control effects, achieve excellent manufacturability, prolong service life, and meticulous design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

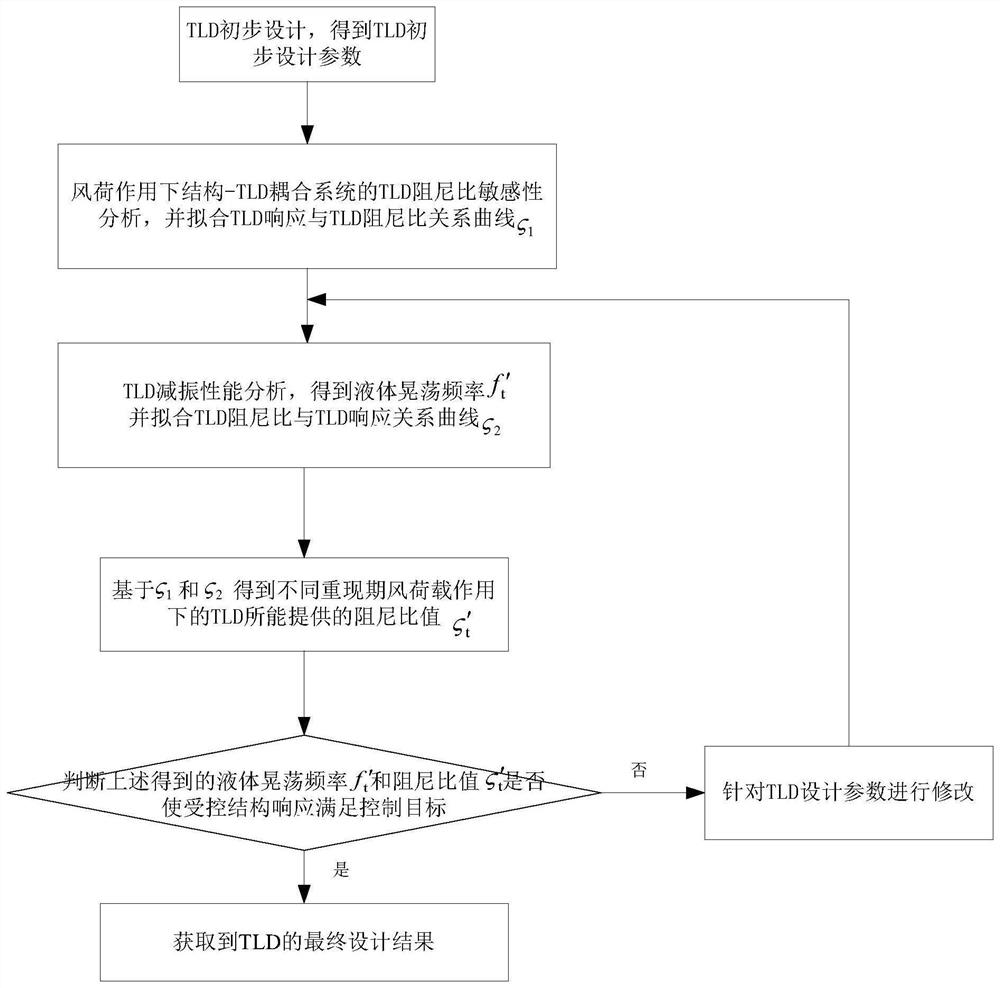

[0062] This embodiment discloses a method for designing a tuned liquid damper, such as figure 1 As shown in , the specific steps include:

[0063] Step 1. Obtain the mass ratio μ and liquid sloshing frequency f of the structure-TLD coupling system required by the design t and TLD damping ratio The preliminary design of TLD is carried out by the equivalent linearization method, and the preliminary designed TLD outline size, liquid depth and design parameters of built-in energy dissipation devices are obtained.

[0064] The mass ratio μ and liquid sloshing frequency f of the structure-TLD coupling system t and TLD damping ratio It is obtained according to the information required by the project design. Based on the above parameters, the preliminary design of the TLD can be carried out through the equivalent linearization method.

[0065] In this embodiment, the built-in energy dissipation device of the TLD is made of fiber-reinforced plastic. Fiber-reinforced plastic (FRP)...

Embodiment 2

[0129] This embodiment discloses a tuning liquid damper design device, including the following functional modules:

[0130] TLD preliminary design module, used to obtain the mass ratio μ and liquid sloshing frequency f of the structure-TLD coupling system required by the design t and TLD damping ratio Preliminary design of TLD is carried out by equivalent linearization method, and the preliminary designed TLD outline size, liquid depth and design parameters of built-in energy dissipation device are obtained;

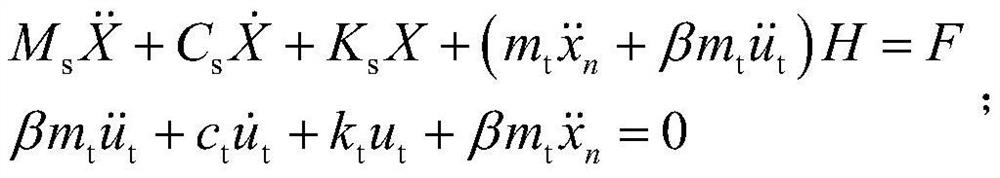

[0131] Building blocks for the equations of motion of structure-TLD coupled systems;

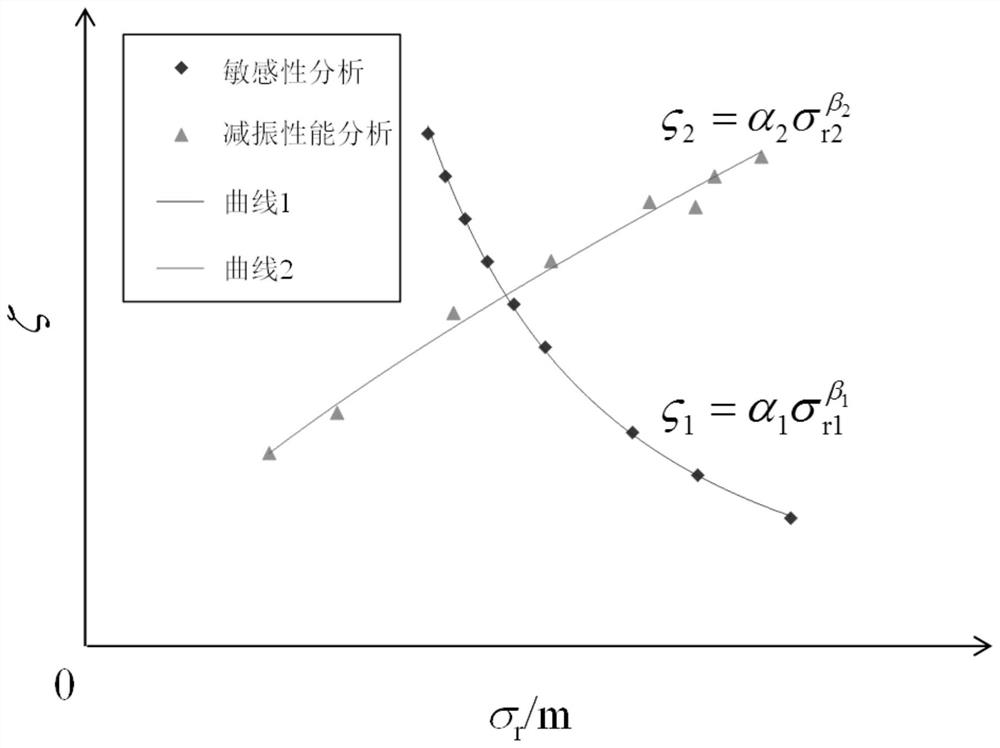

[0132] The sensitivity analysis and fitting module is used to analyze the sensitivity of the TLD damping ratio of the structure-TLD coupling system under different return period wind loads, and to fit the relationship curve between the TLD response and the TLD damping ratio;

[0133] The modal parameter identification and fitting module is used to decouple and separate the measured ...

Embodiment 3

[0139] This embodiment discloses a storage medium, which stores a program. When the program is executed by a processor, the method for designing a tuning liquid damper described in Embodiment 1 is implemented, as follows:

[0140] Step 1. Obtain the mass ratio μ and liquid sloshing frequency f of the structure-TLD coupling system required by the design t and TLD damping ratio The preliminary design of TLD is carried out by the equivalent linearization method, and the preliminary designed TLD outline size, liquid depth and design parameters of built-in energy dissipation devices are obtained.

[0141] Step 2. Construct the structure-TLD coupling system motion equation, analyze the sensitivity of the TLD damping ratio of the structure-TLD coupling system under different return period wind loads, and fit the relationship curve between the TLD response and the TLD damping ratio.

[0142] Step 3. Based on the current design of the TLD, conduct a shaking table test or numerical si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com