Oil-immersed three-phase transformer

A three-phase transformer, oil-immersed technology, applied in the field of electric power, can solve the problems of high temperature of the transformer device, no fluidity of oil, and inability to dissipate and remove the heat of the transformer case in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

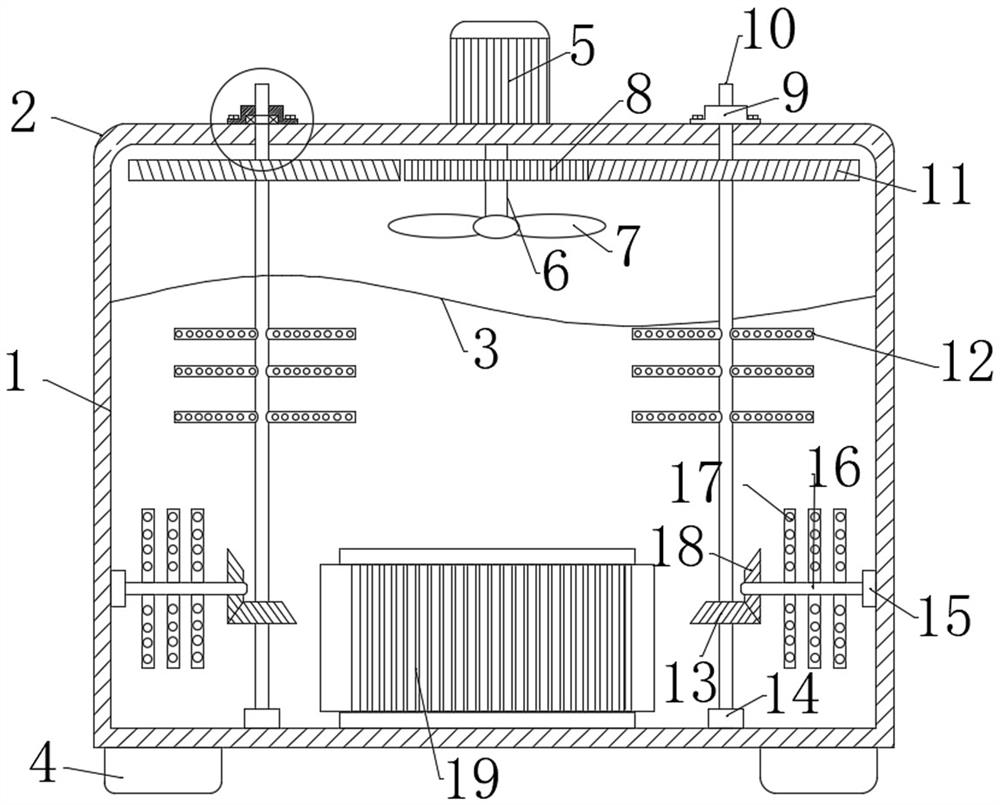

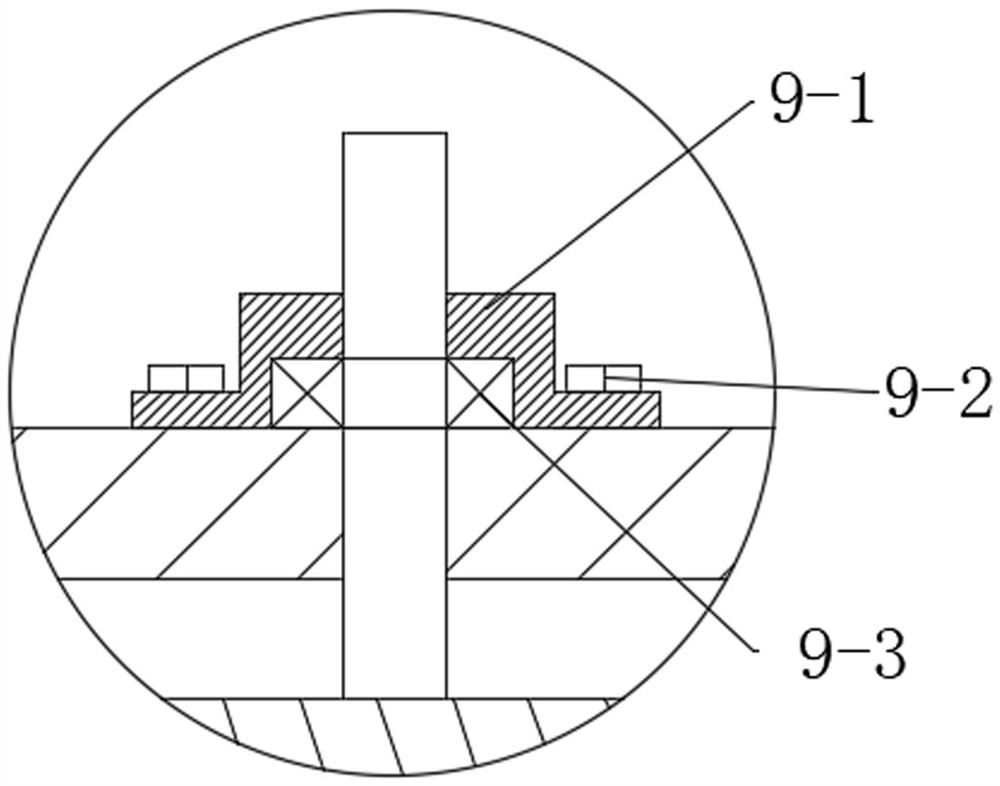

[0023] see Figure 1~3 , in the embodiment of the present invention, a kind of oil-immersed three-phase transformer comprises cabinet 1, and the effect of cabinet 1 is to receive the device inside; Motor 5 is installed on the top of cabinet 1, and motor 5 is the power unit of whole stirring device; Motor The output end of 5 is equipped with rotating shaft 6, and fan blade 7 is installed on the surface of rotating shaft 6, and the function of fan blade 7 is to cool down the part with higher temperature of the liquid surface on the top of engine oil; A bearing seat 9 is installed on the top side of the bearing seat 9, a second shaft 10 is installed inside the bearing seat 9, a second gear 11 is installed on the shoulder of the second shaft 10, and the gear 8 and the second gear 11 mesh with each other. Here The function of meshing is for transmission; the middle part of the second rotating shaft 10 is equipped with a stirring shaft 12, and the stirring shaft 12 is a device for s...

Embodiment 2

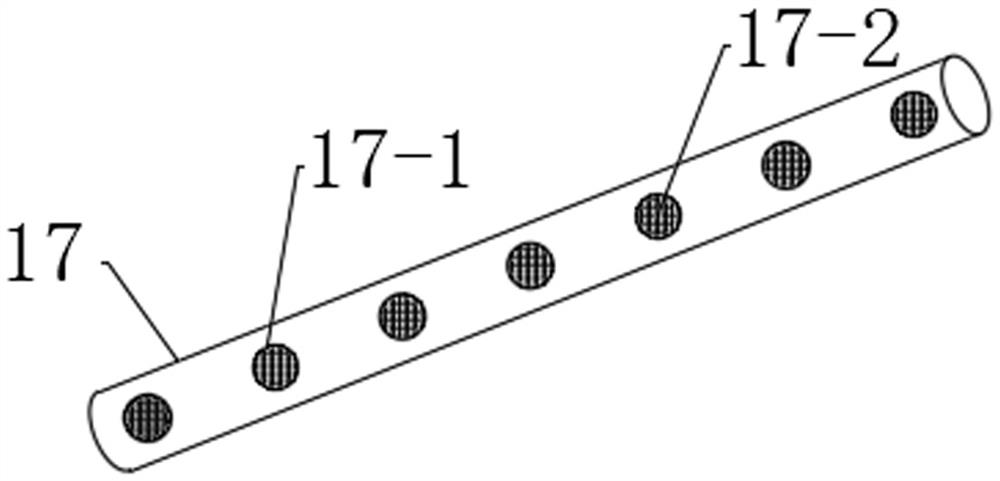

[0027] see figure 1 The difference between the embodiment of the present invention and embodiment 1 is that a third bearing seat 15 is installed on one side of the cabinet 1, a rotating rod 16 is installed in the middle of the third bearing seat 15, and a stirring rod is installed on the surface of the rotating rod 16 Device 17, the stirring rod device 17 is the same device as the above-mentioned stirring shaft 12, and its main function is to stir the part with poor fluidity at the bottom of the device; the side of the rotating rod 16 away from the third bearing seat 15 is equipped with a second The gear 18, the bevel gear 13, and the second bevel gear 18 mesh with each other, and the meshing of the bevel gears is also the effect of realizing the transmission.

[0028] Stirring rod device 17 comprises the mesh 17-1 that offers on its surface, and the inside of mesh 17-1 is fixedly installed with mesh yarn 17-2, and mesh yarn 17-2 can increase the smooth flow effect of stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com