Motor line protection device

A line protection and equipment technology, applied in emergency protection circuit devices, electrical components, etc., can solve problems such as poor motor protection effect, achieve stable power connection, ensure stability, and avoid sudden short-term overload effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

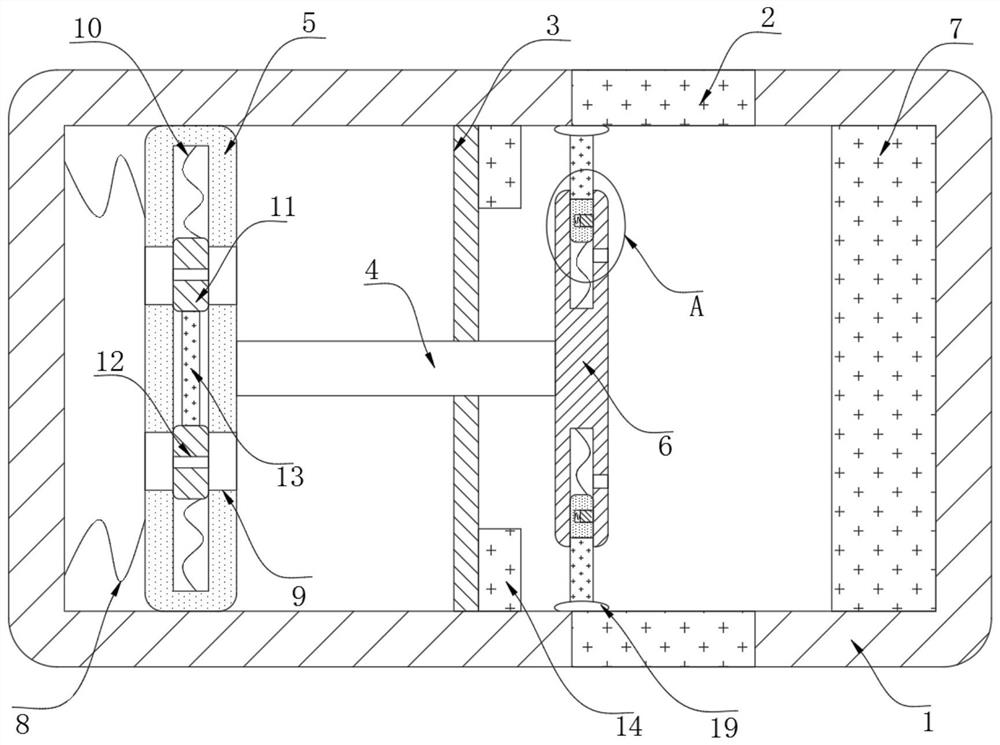

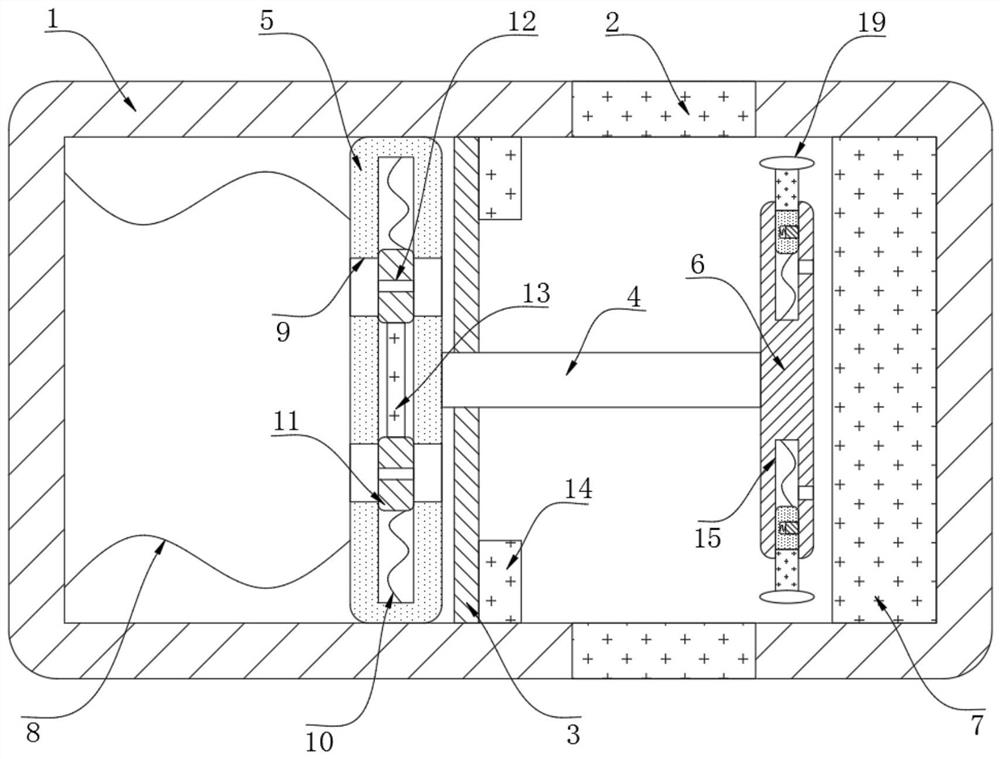

[0021] Refer Figure 1-3 One motor line protection device includes the outer casing 1, and the outer walls of the outer casing 1 are inserted with two pieces of patch block 2, and the inner wall of the outer casing 1 fixes the separator 3, the side wall sealing of the separator 3 is slidable. The connecting rod 4, two ends of the link 4 respectively secure the finite spool 5, and the inner wall of the outer casing 1 fixes the electromagnet 7, and the inside of the limiter box 5 is provided with a control speed mechanism. The end is equipped with a connecting mechanism.

[0022] The control speed mechanism includes two transfer grooves 9 extending through the sidewall of the speed limit box 5, and the two-symmetrical inner walls of the speed limit box 5 are connected by the storage spring 10, and the two baffles 11 are commonly fixed with telescopic rods 13. The sidewalls of the two baffles 11 are formed through the microfillet 12, and the outer casing 1 is filled with hydraulic oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com