Compacting intertillage weed extractor

A weeder and frame technology, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve problems such as crop production loss, accidental injury to crop plants by hooking, and misalignment between the loosening shovel and the row.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

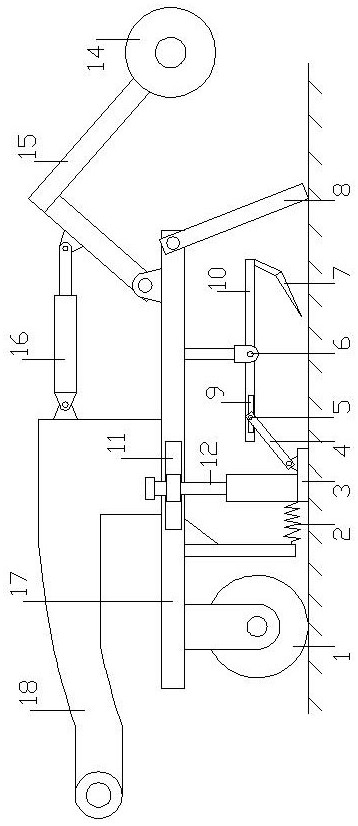

[0017] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0018] Such as figure 1 Shown is a suppression cultivator weeder, including traction equipment and a frame 17 connected to the rear of the traction equipment, and a suppression wheel 1, a soil plate group and a hoeing shovel group installed on the frame sequentially from front to back, traction Equipment adopts prior art, for example tractor, not drawn in the figure.

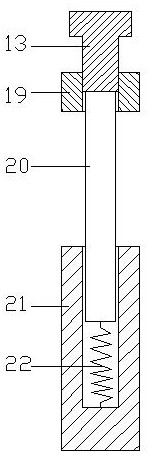

[0019] The earthen board group includes several earthen boards 3 arranged continuously along the left and right directions, and the bottom surface of the earthen board is provided with hemp rope pattern or wave pattern, which increases the crushing effect on the soil clods. The front end of soil plate 3 is connected with frame by transverse spring 2, and the vertical bar that extends downwards is fixedly connected on frame, and the front end of transverse sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com