Automatic adsorbent filling device for air separation radial flow adsorber

An automatic filling and adsorbent technology, which is applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of internal grid deformation, low filling efficiency, and inability to completely ensure uniform filling of adsorbents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

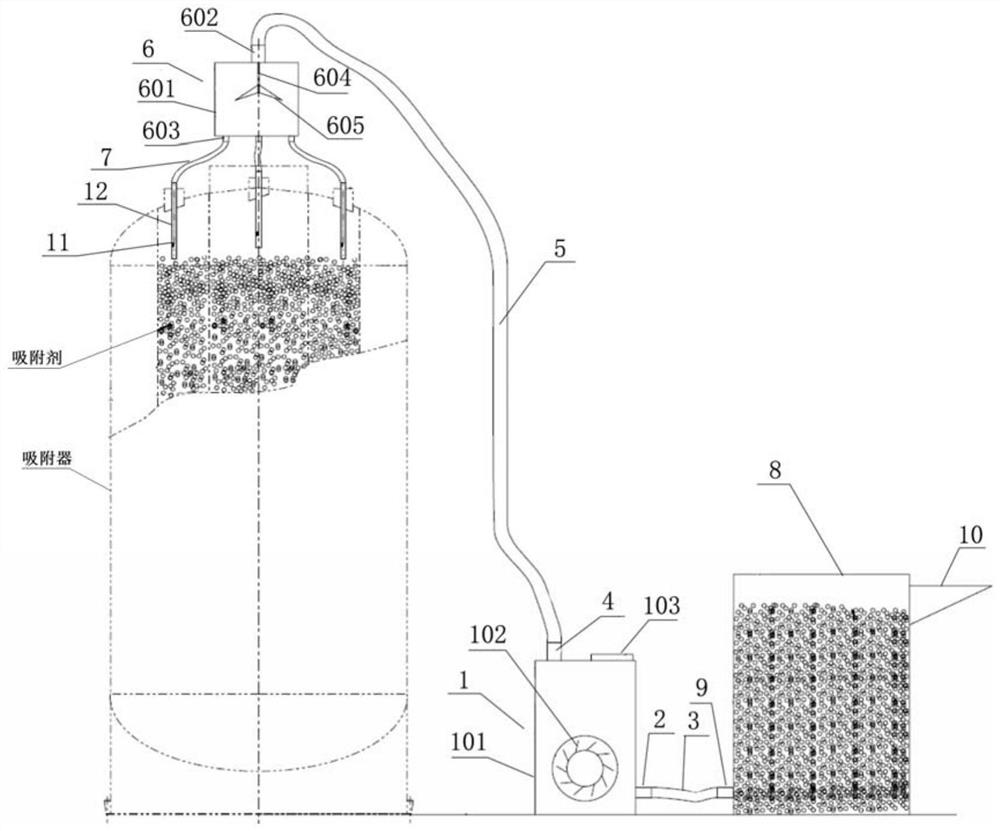

[0029] Such as figure 1 Shown, a kind of air separation radial flow adsorber adsorbent automatic filling device comprises a suction mechanism 1, an inlet pipe 3 connected to the material inlet 2 of the suction mechanism 1 at one end, and an inlet pipe 3 connected at one end to the suction mechanism 1. The outlet pipeline 5 on the material outlet 4 of the suction mechanism 1, which also includes a material equal distribution mechanism 6, the other end of the outlet pipeline 5 is connected with the inlet end of the material uniform distribution mechanism 6, and the material even distribution mechanism The outlet end of 6 is also provided with at least two material conveying pipes 7, one end of which is connected to the outlet end of the material equalizing mechanism 6, and the other end can be freely changed in position. In this way, the inlet pipe 3 on the suction mechanism 1 is connected to the adsorbent storage device, and then the outlet end of the material delivery pipe 7 i...

Embodiment 2

[0036] This embodiment is similar to Embodiment 1, the difference is that, as figure 1 As shown, this embodiment also includes an adsorbent silo 8, the other end of the inlet pipe 3 is connected to the adsorbent outlet 9 at the bottom of the adsorbent silo 8, and the top side of the adsorbent silo 8 is provided with Adsorbent inlet 10. When the adsorbent storage device is inconvenient to be directly connected to the inlet pipe 3 of the suction mechanism 1 , the adsorbent bin 8 can be used to transfer the adsorbent from the adsorbent storage device to the adsorbent bin 8 .

[0037] Such as figure 1 As shown, the end of the material conveying pipe 7 away from the material equalizing mechanism 6 is provided with a flow sensor 11 , and the flow sensor 11 is communicatively connected with the operating system panel 103 . The flow sensor 11 can monitor the flow rate of the adsorbent in each material conveying pipe 7, and transmit the monitoring data to the operating system panel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com