Novel trumpet-shaped forge piece thixotropic forging device and process thereof

A horn-shaped, forging technology, applied in the field of thixotropic forging, can solve the problems of difficult to adjust the spacing, difficult to achieve forging hammer, difficult to forge and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

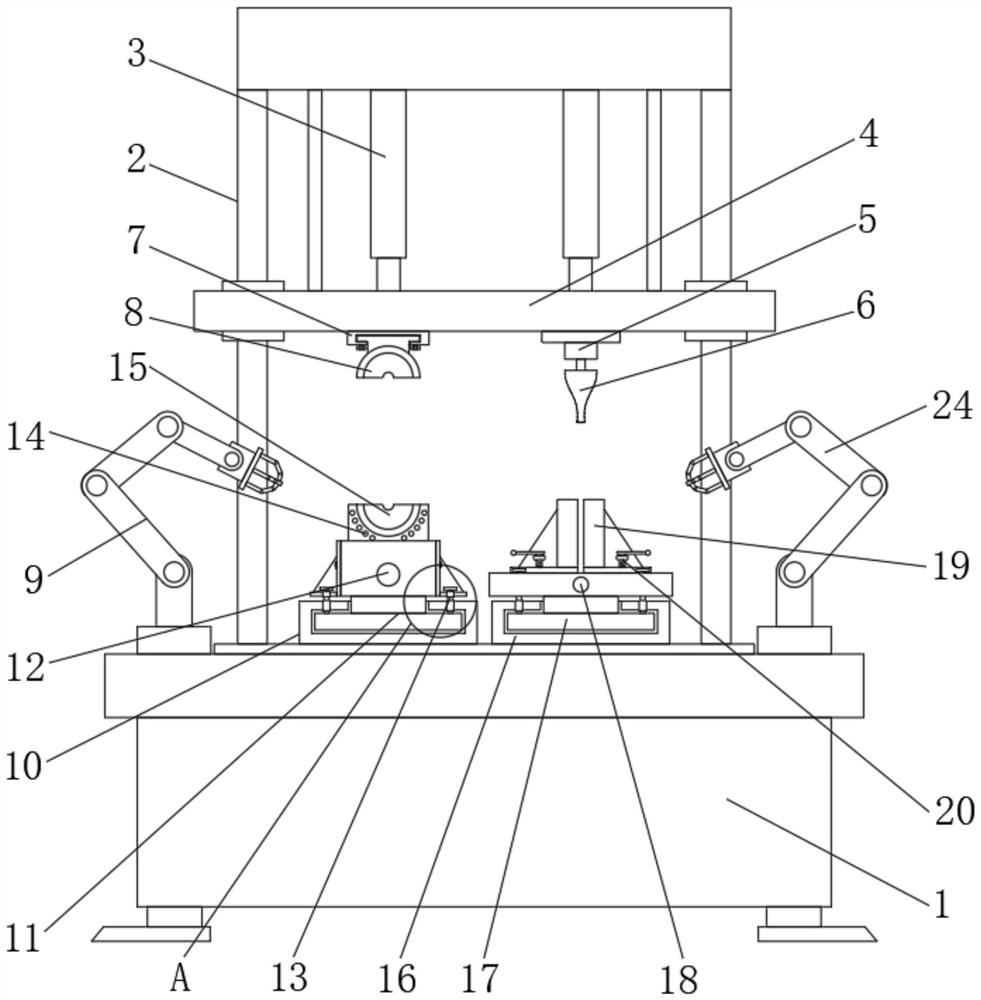

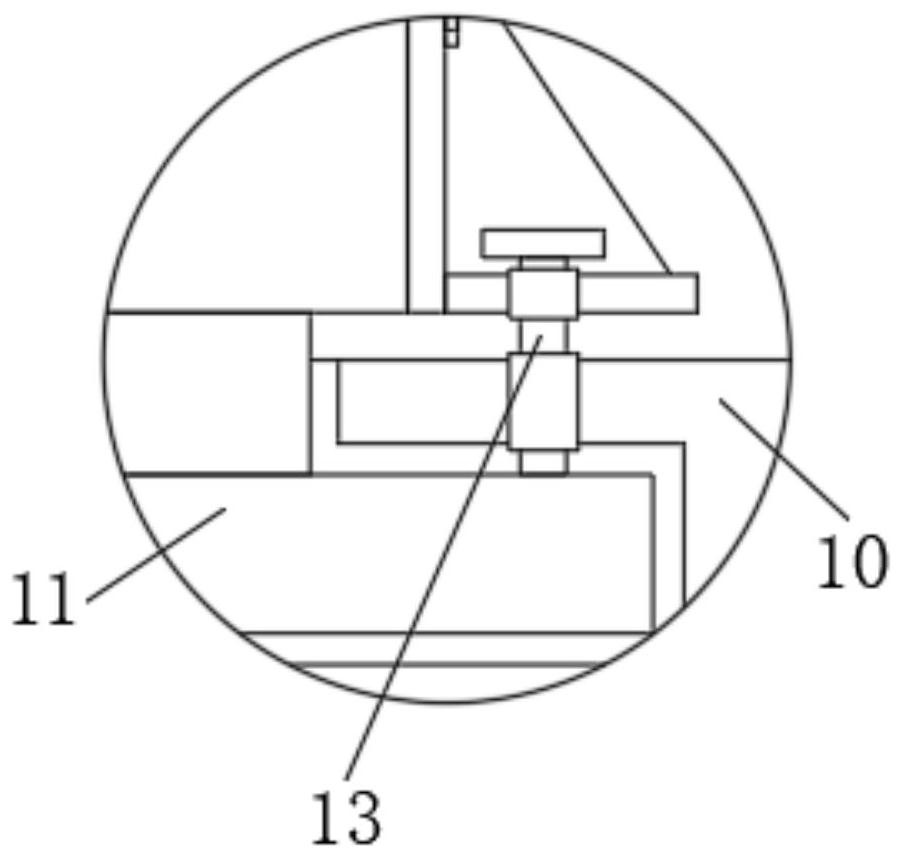

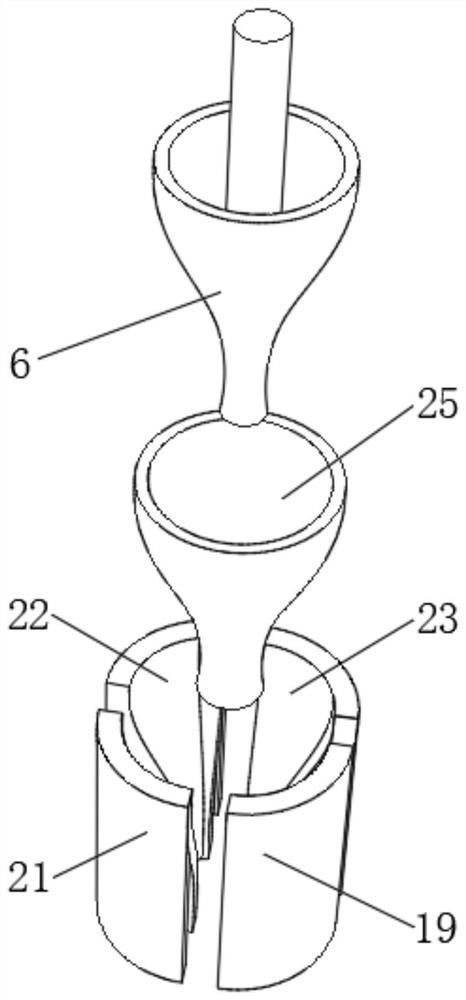

[0038] see Figure 1-7 , a new trumpet-shaped forging thixotropic forging device and its technology, including a control box 1, the top of the control box 1 is fixedly installed with a limit column 2, and the inner side of the top of the limit column 2 is fixedly installed with a first hydraulic rod 3, the first The output end of the hydraulic rod 3 is connected with the extruding panel 4, the lower right side of the extruding panel 4 is fixedly connected with the demolition part 5, the bottom of the dismantling part 5 is fixedly connected with the inner wall impact part 6, and the left side of the dismantling part 5 is fixedly installed with an installation part 7, the interior of the mounting part 7 is connected with an external stamping part 8, the upper left side of the control box 1 is fixedly installed with the first manipulator 9, and the right side of the first manipulator 9 is fixedly installed with the first adjustment slide rail 10, the first adjustment The inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com