Connecting mechanism for hexagonal omnidirectional mobile robot

A mobile robot and connection mechanism technology, applied in the field of mobile robots, can solve the problems of insufficient connection, affecting the connection efficiency and cooperation ability of mobile robots, and insufficient fast locking and separation actions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

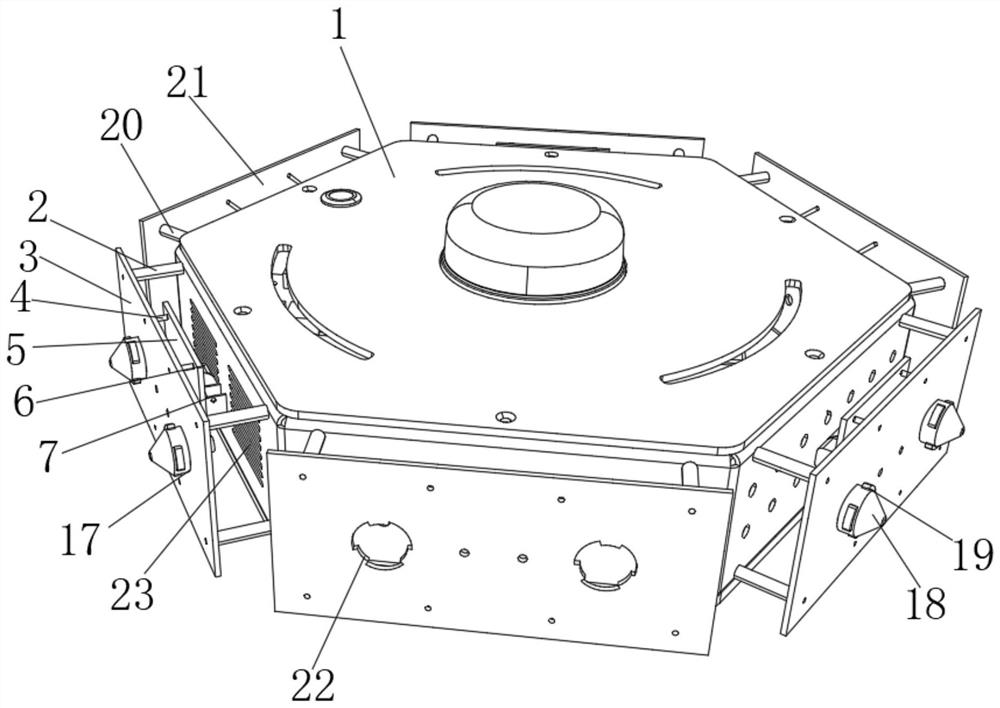

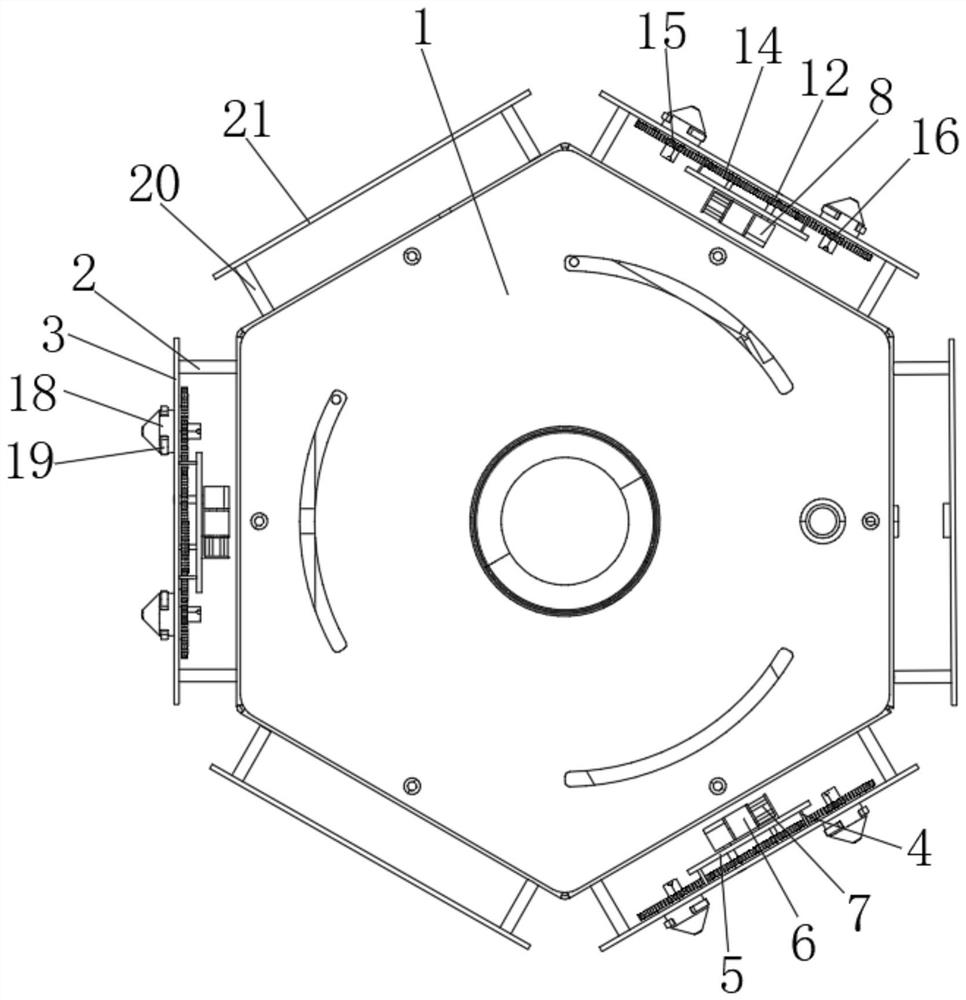

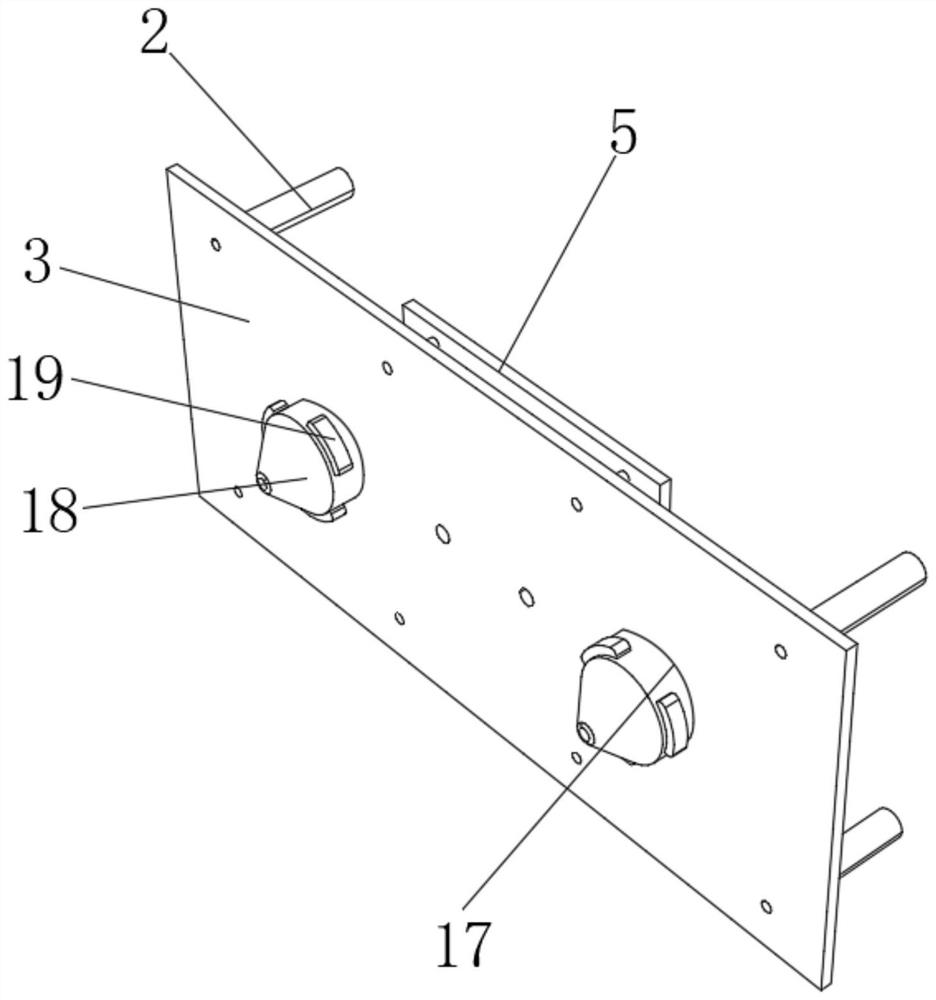

[0031] refer to Figure 1-Figure 5 , a connecting mechanism for a hexagonal omnidirectional mobile robot, comprising a mobile robot body 1 and a power mechanism, the multi-side outer walls of the mobile robot body 1 are fixed with a plurality of first connecting columns 2 by bolts, and the first connecting columns One end of 2 is fixed with a first connection panel 3 by bolts, and one side of the first connection panel 3 is rotatably connected with two third plug-in shafts through an embedding shaft, and one end of the two third plug-in shafts is respectively key-connected with The left guide head drive gear 15 and the right guide head drive gear 16, the other end of the third plug-in shaft is fixed with a tapered guide head 18 by bolts, and the left guide head drive gear 15 and the right guide head drive gear 16 are driven by the power mechanism Rotate together, so that the conical guide head 18 rotates 60 degrees, the outer circumference of the conical guide head 18 is integ...

Embodiment 2

[0036] refer to Image 6 , a connection mechanism for a hexagonal omnidirectional mobile robot, including a side of the first connection panel 3 is also fixed with a guide shaft 24 by bolts, and one side of the second connection panel 21 is provided with a through hole 25, The guide shaft 24 is plugged into the insertion hole 25, and the guide shaft 24 is inserted in the insertion hole 25 to improve the stability of the connection of the mobile robot body 1. One side of the second connection panel 21 is also provided with a groove 26, which One side inner wall of the groove 26 is rotatably connected with a rotating plate 27, and one side of the rotating plate 27 is fixed with a spring 28 by a bolt. Under the elasticity of the spring 28, the rotating plate 27 is rotated to the outside, thereby the other mobile robot body 1 is bounced. To facilitate the separation of multiple mobile robot bodies 1, the other end of the spring 28 is fixedly connected to the bottom inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com