Sofa sponge electric heating automatic cutting device based on Internet of Things

An automatic cutting device, cutting device technology, applied in the direction of metal processing, etc., can solve the problems that the cutting wire cannot adjust the tightness, slipping and positioning, affecting the health of the staff, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

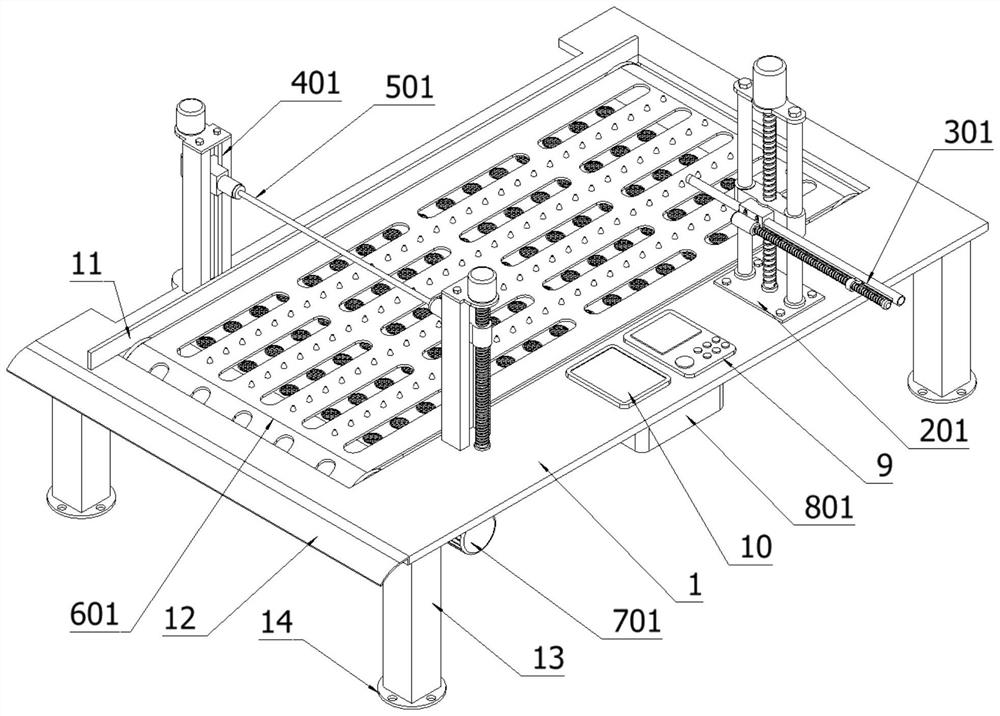

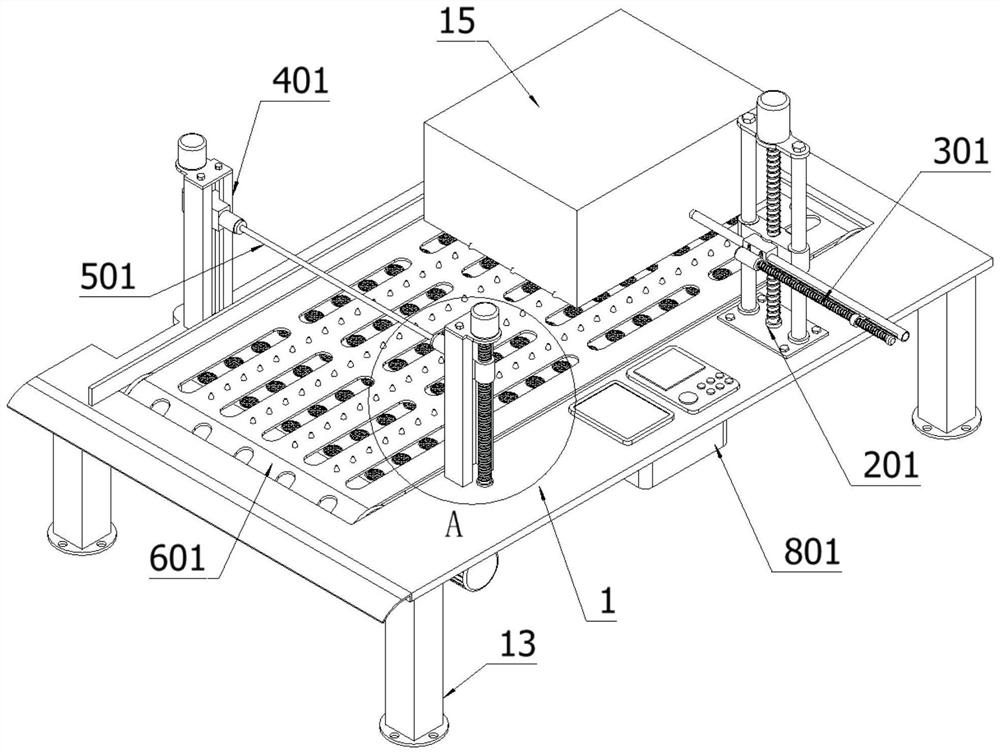

[0042] as attached figure 1 to attach Figure 11 Shown:

[0043] The present invention provides an electric heating automatic cutting device for sofas based on the Internet of Things, which includes an installation base plate 1; four corners of the bottom of the installation base plate 1 are fixedly connected with support legs 13, and the bottoms of the four support legs 13 are fixedly connected with connection feet 14; The top front side of the installation base plate 1 is fixedly connected with the control center 9; the top front side of the installation base plate 1 is fixedly connected with the Internet of Things connection platform 10; the top of the installation base plate 1 is fixedly connected with the punching positioning device 2, and the punching positioning device 2 is fixedly connected There is a telescopic punching and cutting device 3; two cutting driving devices 4 are fixedly connected to the top left side of the top, and an elastic cutting device 5 is fixedly...

Embodiment 2

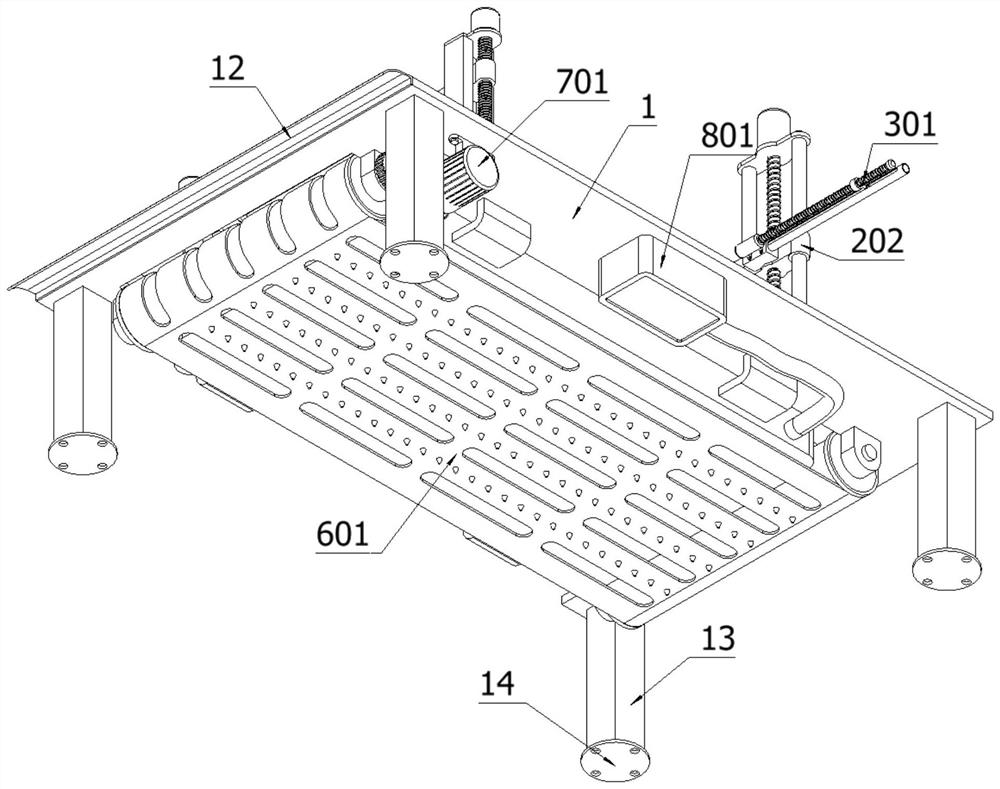

[0051] Such as Figure 12As shown, in the second embodiment, other structures remain unchanged, and the present invention provides another structural form of the air suction bellows 803, so that the suction force of the air suction bellows 803 is concentrated in the air suction slots 602, solving the problem of the air suction bellows. 803 is prone to friction with the sponge running belt 601; the positioning absorption device 8 includes: suction pump 801, bellows connection bracket 802, suction bellows 803, suction network port 804 and connecting hose 805, fixed connection at the bottom of the installation base plate 1 There is a suction pump 801, and the suction pump 801 is connected to a suction bellows 803 through a connecting hose 805; four bellows connecting brackets 802 are fixedly connected to the bottom of the installation base plate 1, and four bellows connecting brackets 802 are fixedly connected to a suction bellows Bellows 803; the top of the suction bellows 803 i...

Embodiment 3

[0053] Such as Figure 14 As shown, on the basis of the second embodiment, other structures remain unchanged. The present invention provides another structural form of the air suction slot 602. The air suction slot 602 adopts a strip-shaped slotting method, which can simultaneously accommodate The four suction mesh ports 804, while ensuring the firm and stable operation of the operating device 6, maximize the suction air volume of the suction mesh ports 804 on the suction bellows 803, so as to realize the transportation of larger volumes of sponge blocks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com