Full-automatic in-mold labeling and visual detection system

A visual inspection and in-mold labeling technology, applied in labeling machines, labels, conveyor objects, etc., can solve the problems of low production efficiency and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

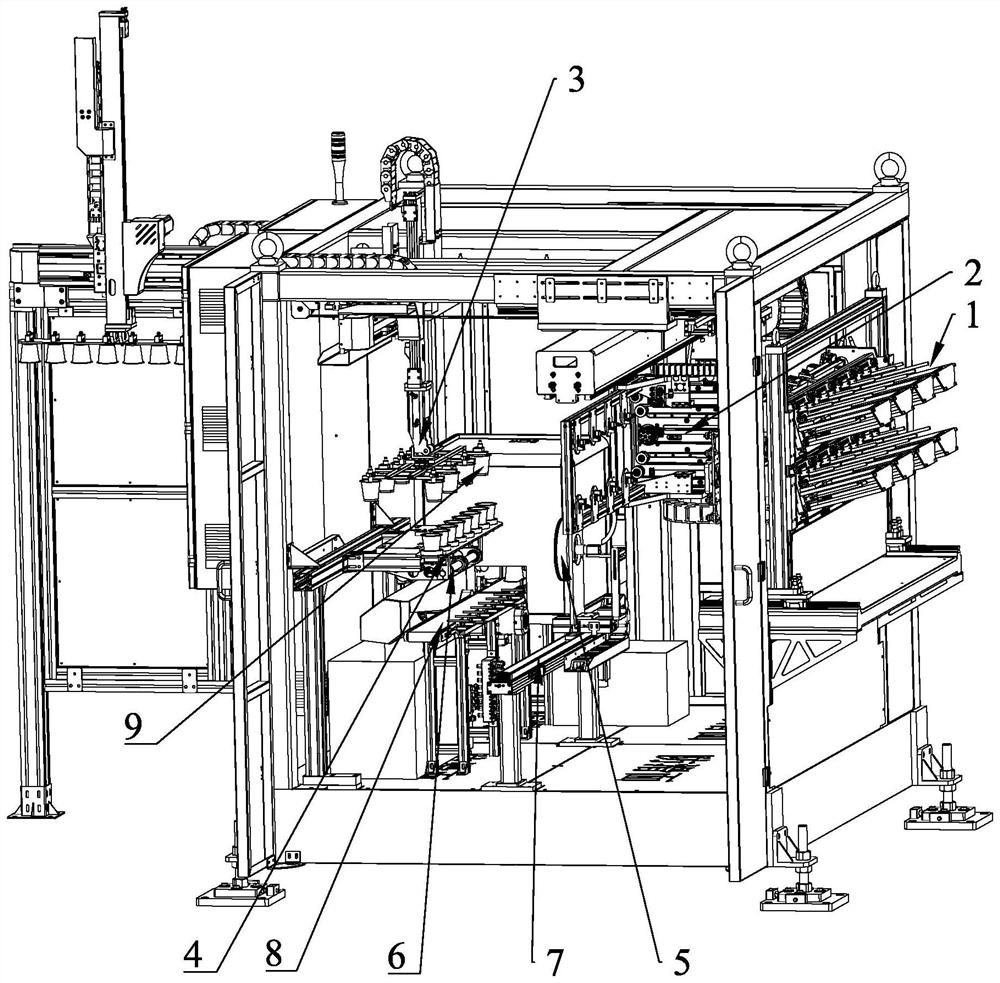

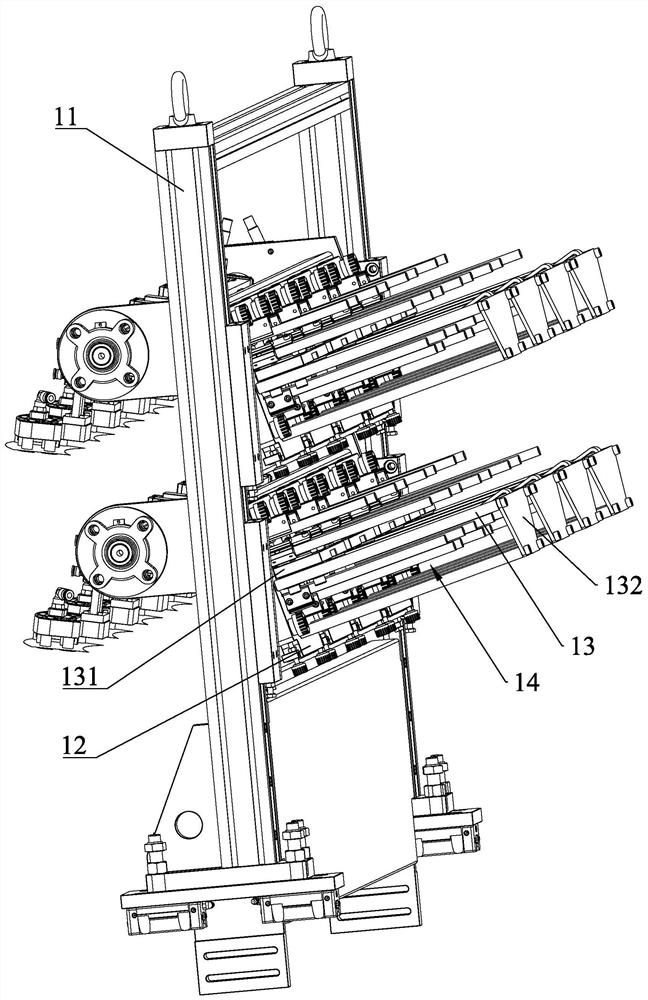

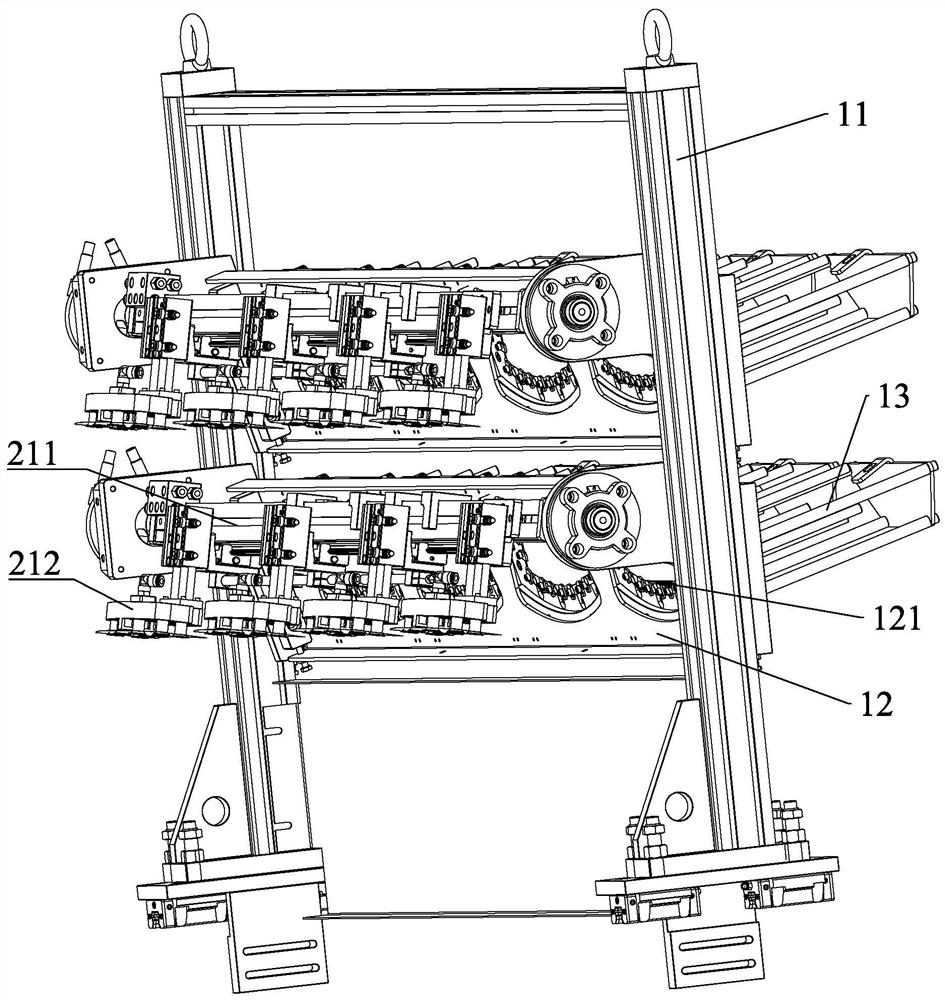

[0038] see figure 1 , Figure 10 and Figure 12 , the invention discloses a fully automatic in-mold labeling visual inspection system for in-mold labeling and visual inspection of cup-shaped products, which includes a loading rack 1, a labeling device 2, a material transfer device 3, a product Receiving platform 4 , first visual inspection device 5 , turning mechanism 6 , reciprocating device 7 and conveying line 8 . The loading rack 1 is used for storing labels. The labeling device 2 is used to place the label on the material carrier 1 into the mold cavity and take out the cup-shaped product 9 that has been injection molded and labeled. The material shifting device 3 is used to transfer the cup-shaped product 9 that is taken out. The product receiving platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com