Automatic conveying system for craft home textiles and method

A technology of automatic conveying and craftsman, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as affecting normal use, the hanging hanger is not firmly clamped, and cannot be buckled into the chain clip.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

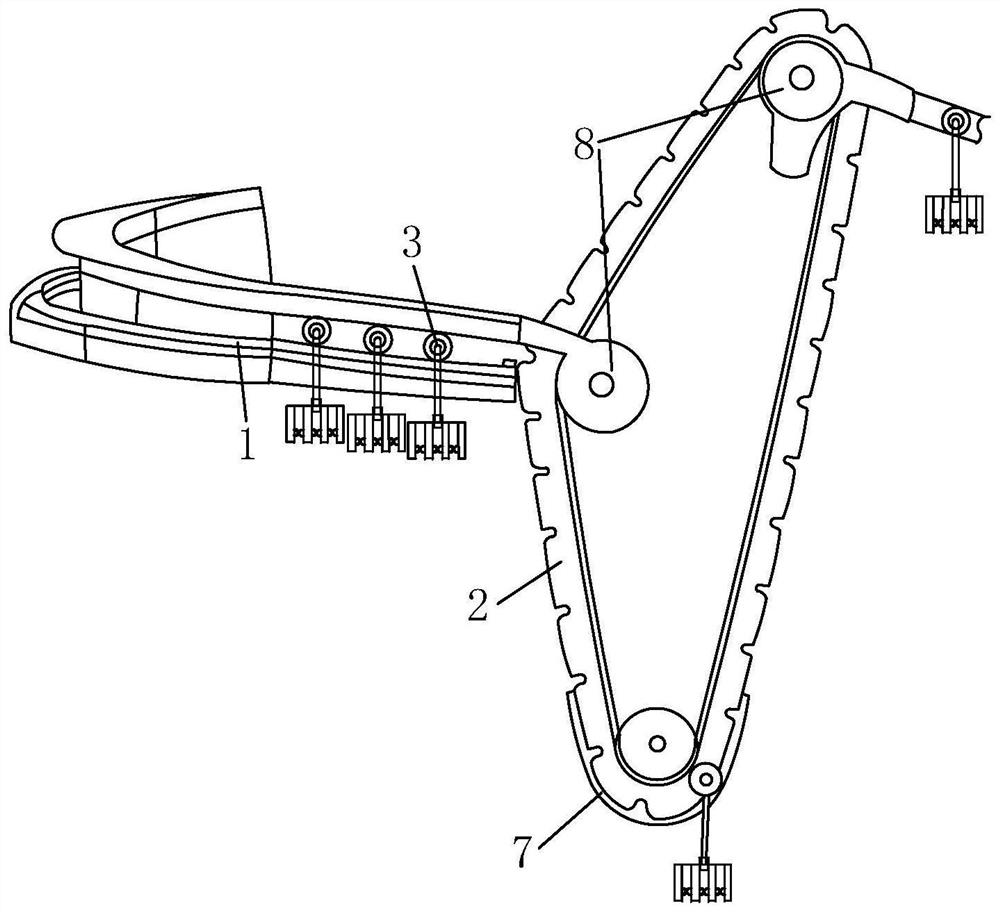

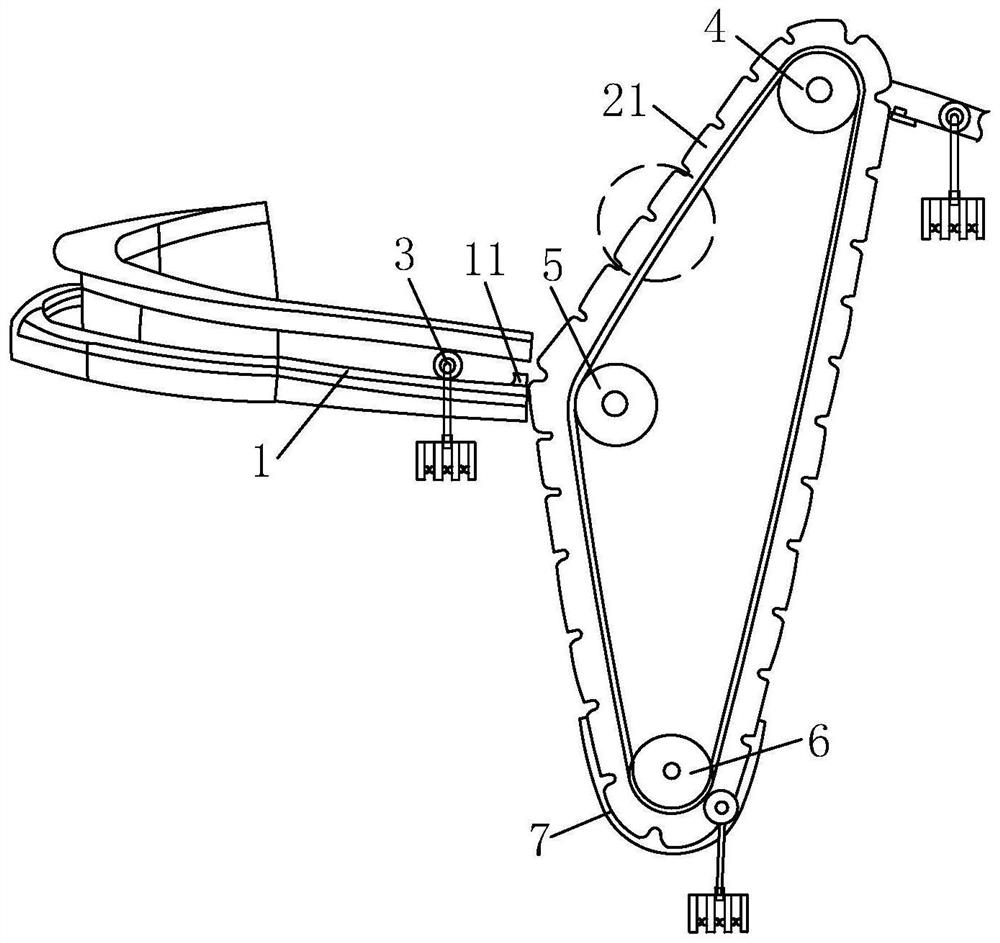

[0026] Such as figure 1 The shown automatic conveying system for craft home textiles includes a conveying station and an inspection station. The conveying station transports processed home textile products to the inspection station for inspection. The conveying station includes a circular track 1, a conveying mechanism, and a crane for conveying home textile products. The hanger 3, the hanger 3 is transported to the entrance of the conveying mechanism through the circular track 1, and then the home textile products are conveyed to the exit of the conveying mechanism through the conveying chain 2, and the exit of the conveying mechanism is connected to the subsequent conveying track ;

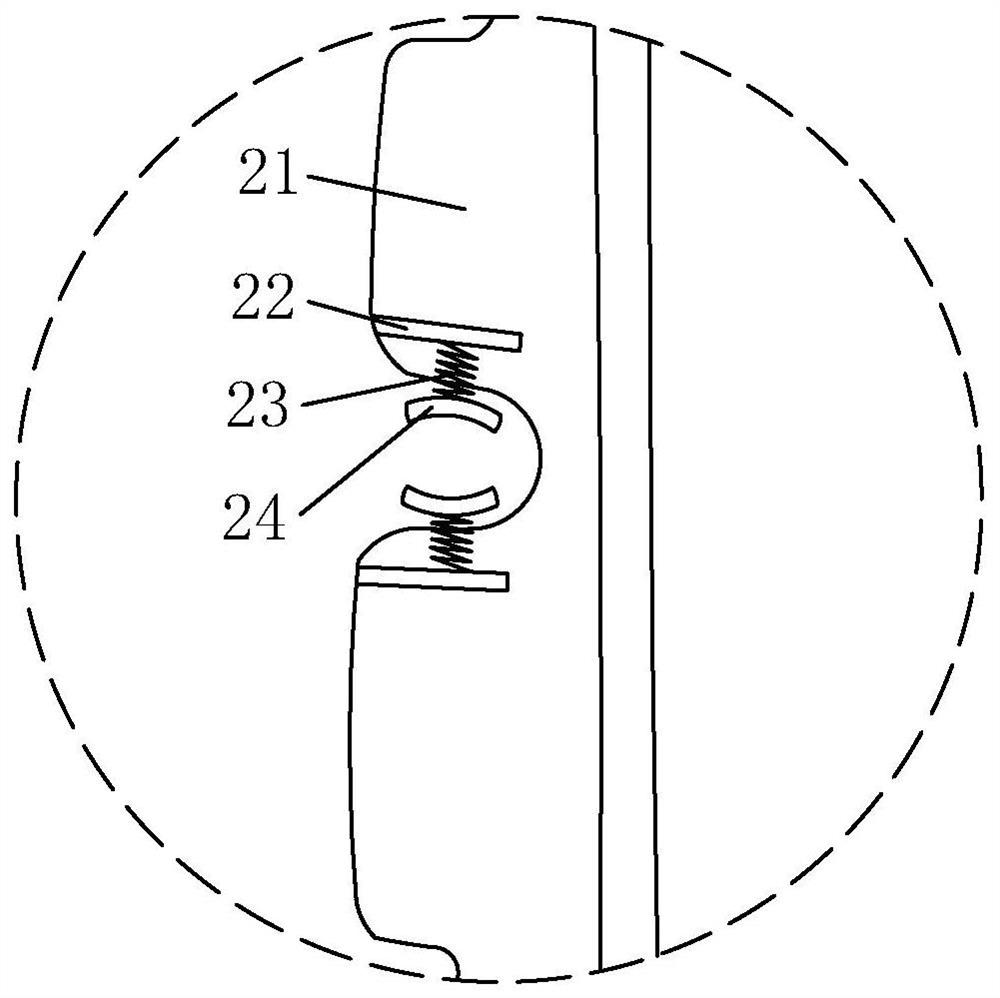

[0027] Wherein, one end of the circular track 1 close to the conveying mechanism is provided with an upwardly protruding blocking plate 11, and the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com