Preparation method of retarding superplasticizer

A high-efficiency water-reducing agent and retarding technology, applied in the chemical industry, can solve the problems of affecting the crushing quality of asbestos lint, uneven crushing of asbestos lint, and affecting the working environment of staff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

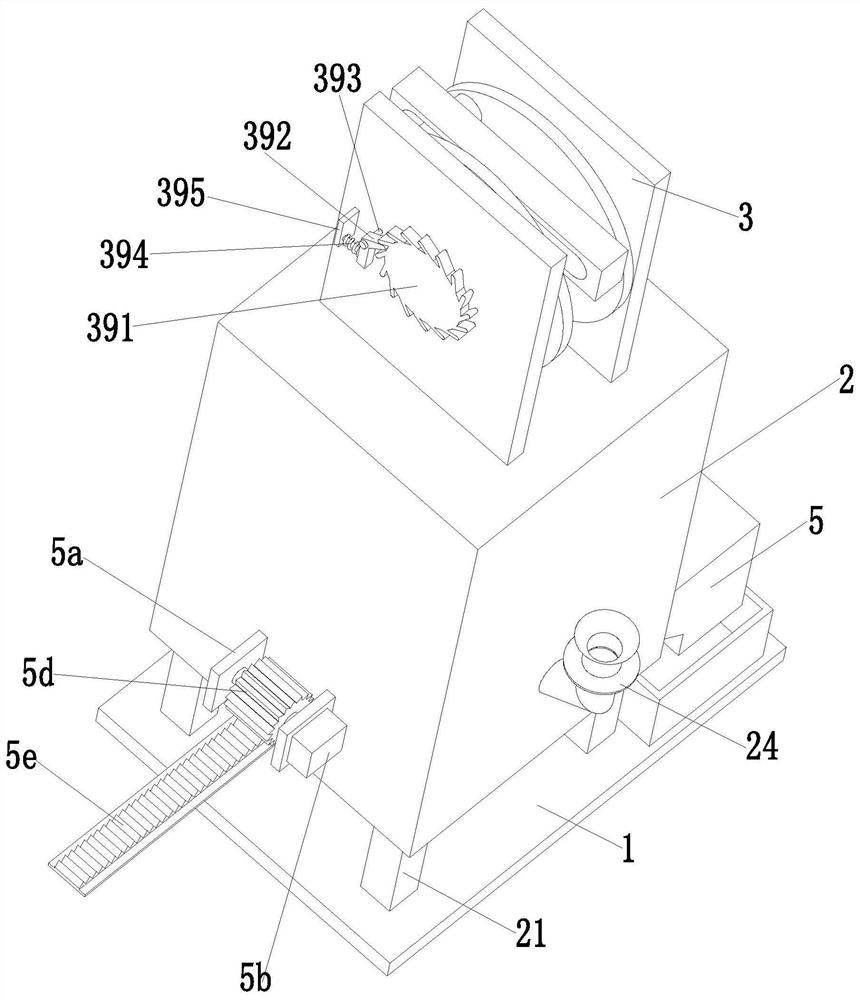

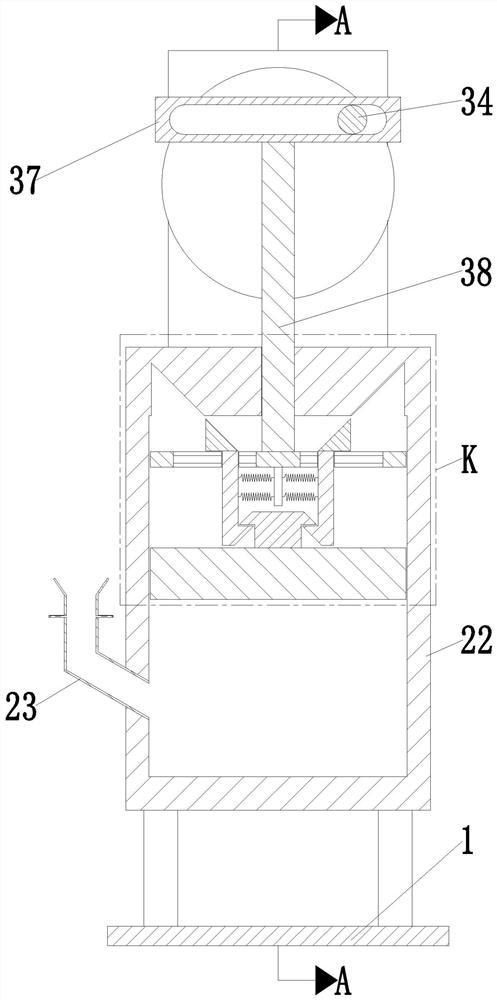

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

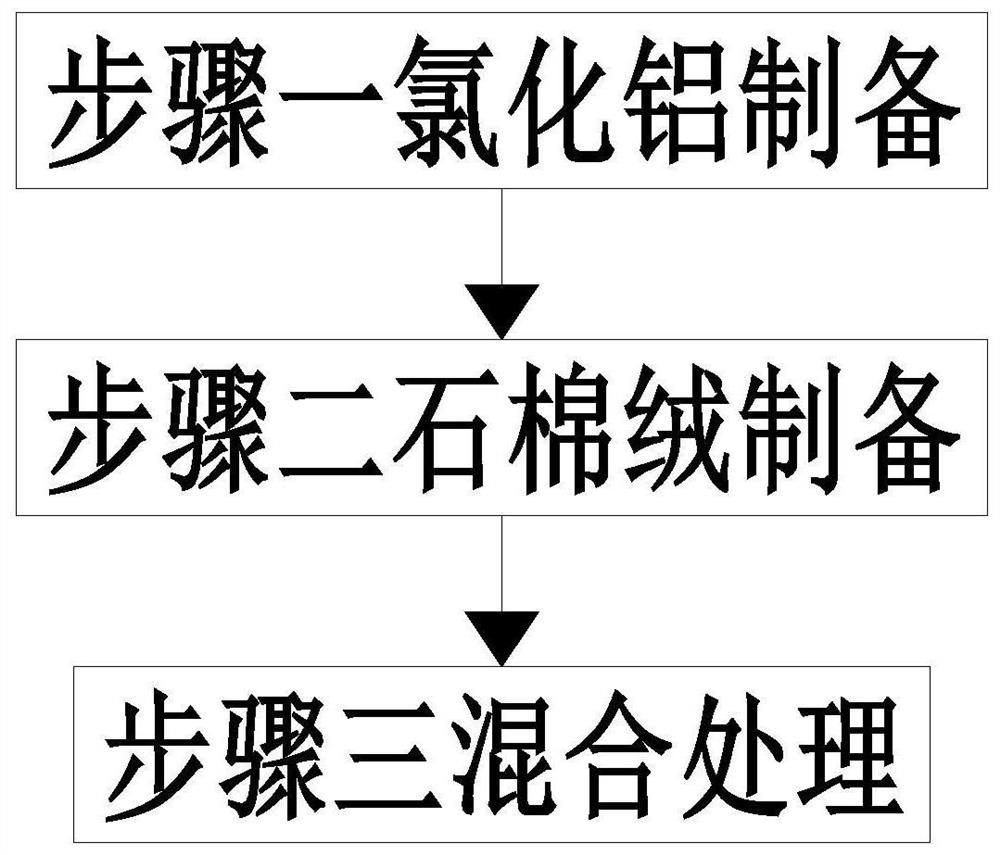

[0034] Such as Figure 1 to Figure 10 Shown, a kind of retarding high-efficiency superplasticizer preparation method mainly comprises the following steps:

[0035] Step 1, preparing aluminum chloride, mixing and stirring polyaluminum chloride and sodium polyaspartate, and pulverizing to obtain modified polyaluminum chloride;

[0036] Step 2, preparation of asbestos wool, adding deionized water to the asbestos wool, then adding cocoic acid diethanolamide and initiator, and undergoing microwave reflux and concentration to obtain asbestos wool blocks, and then crushing them through asbestos wool crushing equipment , to obtain modified asbestos wool;

[0037] Step 3, mixing treatment, after mixing the polycarboxylic acid mother liquor and allyl polyoxye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com