Method and device capable of effectively reducing SiC single crystal defects

A single crystal and defect technology, applied in the field of effectively reducing SiC single crystal defects, can solve problems such as low utilization rate of SiC raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

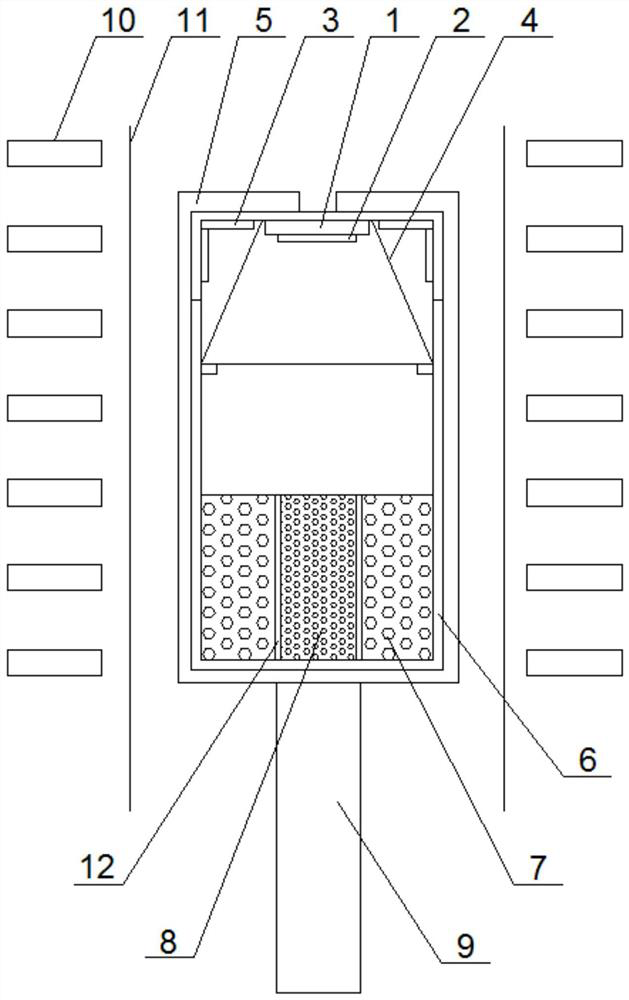

[0034] Embodiment 2 is a method for preparing a SiC single crystal using the device described in Embodiment 1, which specifically includes the following steps:

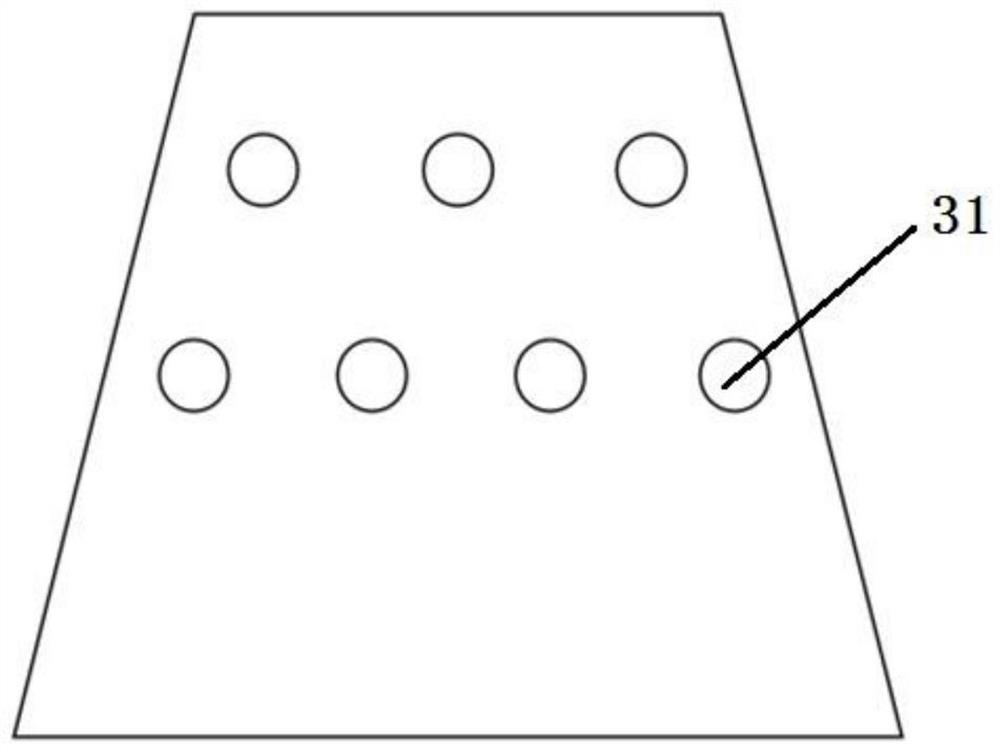

[0035] S1. First place the annular graphite filter screen 12 vertically in the center of the crucible main body 6, then fill the silicon carbide raw material 1 7 into the annular graphite filter screen 12, and then fill the silicon carbide raw material 2 8 into the annular graphite filter screen 12 The outer periphery is flattened, and then the shroud 4 is placed on the boss of the inner wall of the crucible main body 6, and then the graphite sheet 3 is respectively pasted on the circumferential inner wall of the top opening of the crucible main body 6 and the crucible cover on the outer periphery of the seed crystal holder 1, Finally, paste the seed crystal 2 on the seed crystal support 1 , and close the crucible lid on the crucible main body 6 .

[0036] S2. After wrapping the insulation material 5 on the outside of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com