Pile-beam integrated fully-prefabricated assembled bridge substructure, bridge and construction method thereof

A technology of prefabricated assembly and construction method, applied in infrastructure engineering, erection/assembly of bridges, bridges, etc., can solve problems such as high material consumption, many on-site procedures, and easy environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

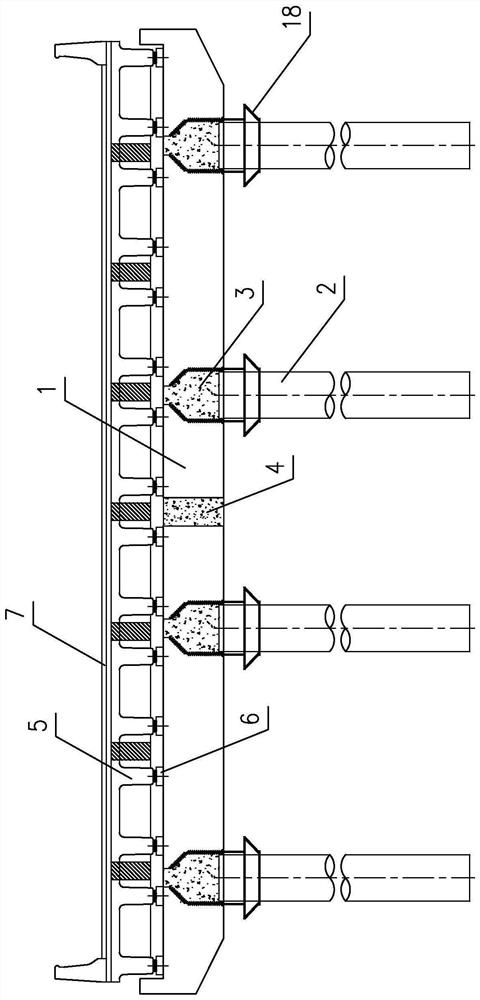

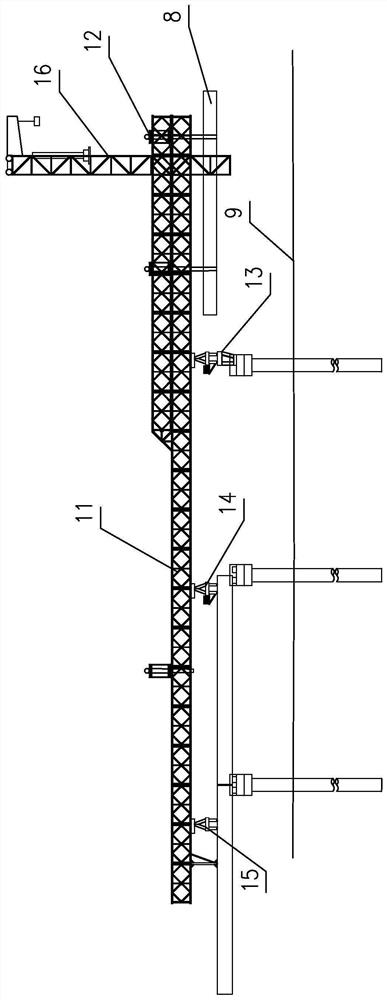

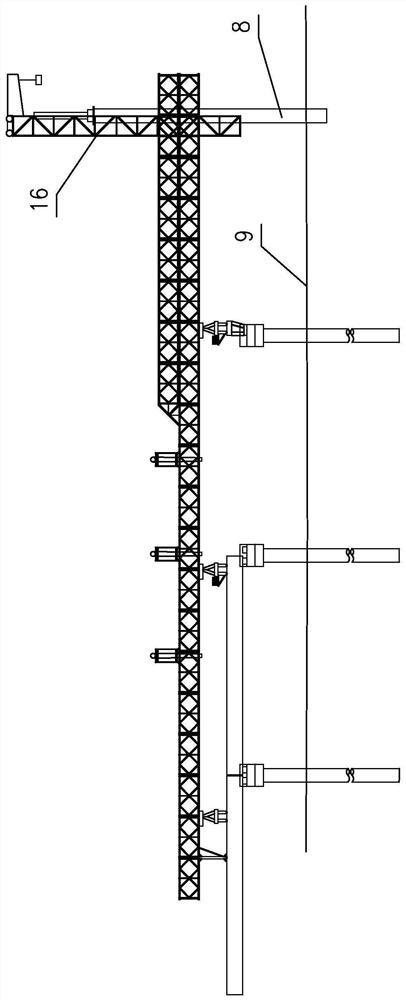

[0035] Such as figure 1 Shown is a pile-beam integrated fully prefabricated assembled bridge substructure of the present invention, which includes a cover beam 1 and a pier column, the cover beam 1 is arranged along the transverse bridge direction, and the pier column is poured in the pile core of the prefabricated concrete pipe pile The precast concrete pipe pile 2 made of concrete, the lower end of the precast concrete pipe pile 2 is fixed in the foundation, the connection node 3 between the upper end and the cover beam 1 and the precast concrete pipe pile 2 are formed by one-time pouring of concrete, so that the prefabricated The concrete pipe pile column 2 is connected with the cover beam 1 as a whole.

[0036] Specifically, a vertical through hole is reserved on the cover beam 1, and a temporary steel hoop 18 is set on the upper end of the precast concrete pipe pile. The cage is inserted into the reserved hole and extends into the prefabricated concrete pipe pile, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com