C-shaped sleeve detachable and replaceable reinforced concrete column-column connecting structure and construction method

A technology of reinforced concrete columns, connecting structures, applied in the direction of columns, pier columns, pillars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

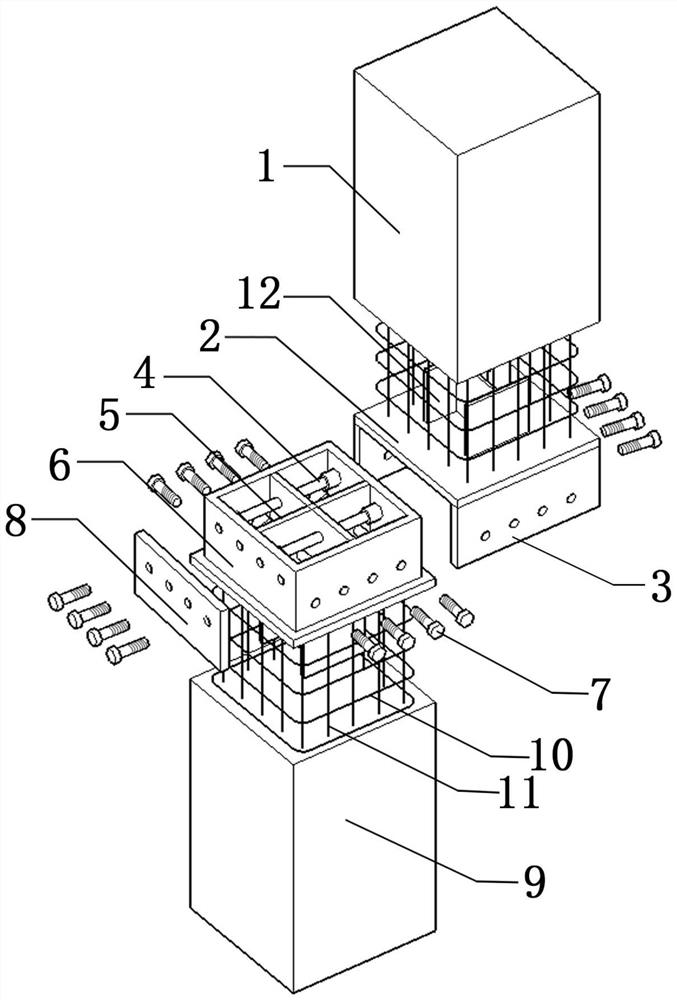

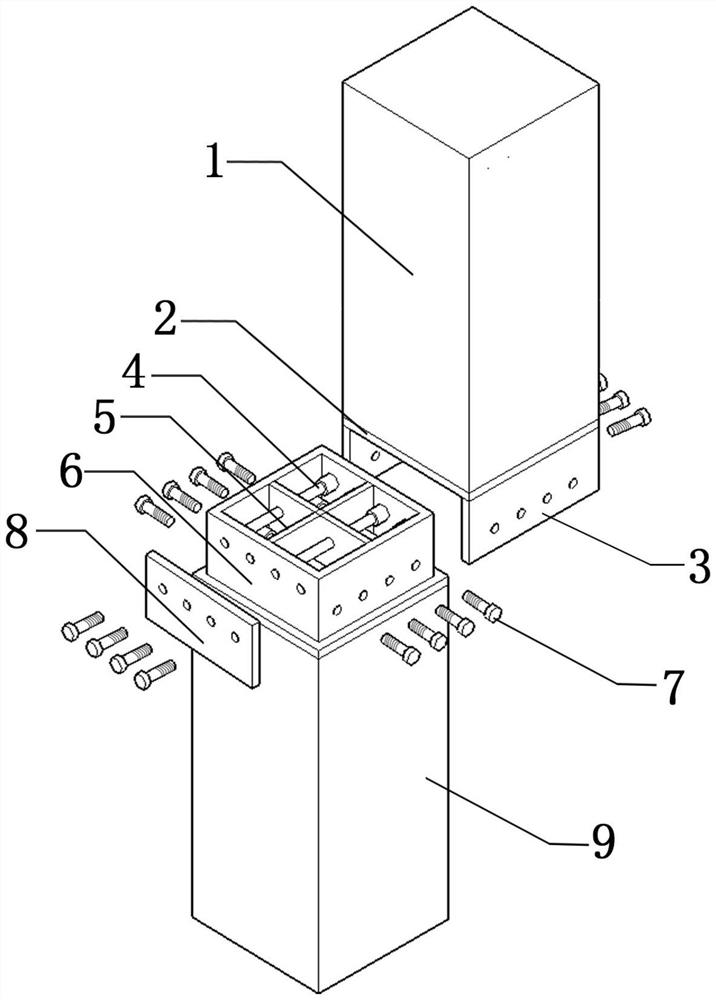

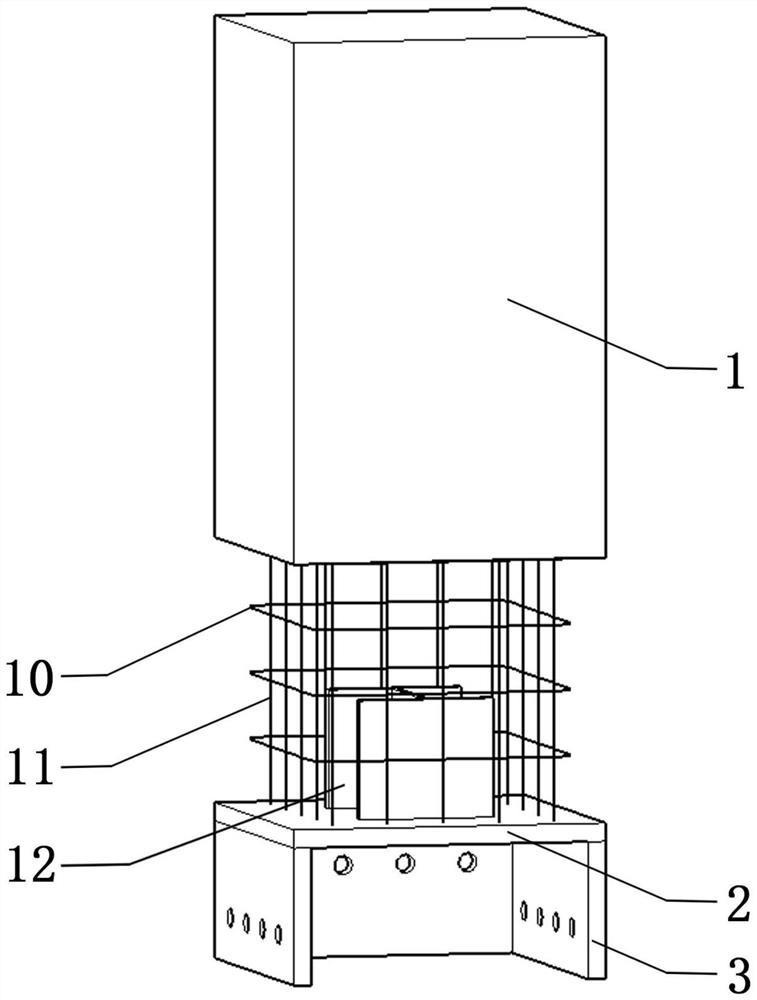

[0032] see Figure 1-Figure 4 As shown, a C-shaped sleeve detachable and replaceable reinforced concrete column-column connection structure includes an upper reinforced concrete column, a lower reinforced concrete column, a cover plate, and high-strength bolts. The upper reinforced concrete column includes a C-shaped outer sleeve, column end steel plate, shear connectors, longitudinal bars, and stirrups; the lower reinforced concrete column includes a rectangular inner sleeve, a combination device of steel pipe and steel sleeve, and a cross-shaped opening Steel plates, shear connectors, longitudinal bars, and stirrups; among them, the embedded shear connectors in the upper and lower columns are placed inside the steel skeleton formed by the longitudinal bars and stirrups, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com