Video-based automatic management system for coal conveying separate warehouse metering

A technology of automatic management and coal transportation, which is applied to the parts of TV system, general control system, control/regulation system, etc., and can solve problems such as damage, failure to warn in time, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

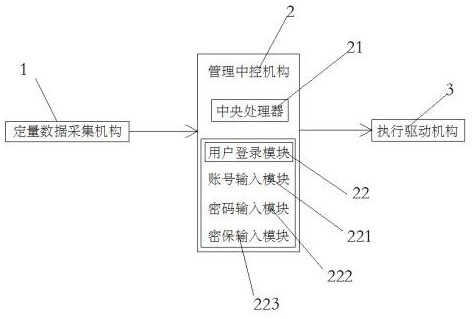

[0030] Example 1 as Figure 1-4 As shown, this video-based automated management system for coal delivery and sub-bin metering includes quantitative data collection mechanism 1, management central control mechanism 2 and execution drive mechanism 3, quantitative data collection mechanism 1, management central control mechanism 2 and execution drive mechanism Mechanism 3 is sequentially connected through wireless signal transmission;

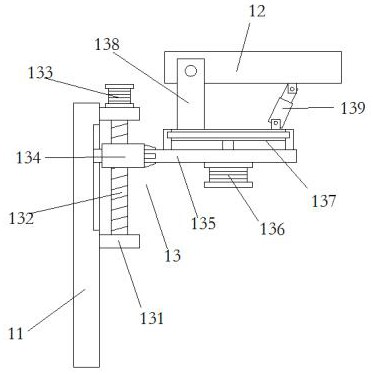

[0031] Quantitative data acquisition mechanism 1 comprises column 11 and video acquisition camera 12, is fixedly connected by adjusting mechanism 13 between column 11 and video acquisition camera 12;

[0032] The management central control mechanism 2 includes a central processing unit 21 and a user login module 22, and the user login module 22 includes an account number input module 221, a password input module 222 and a secret security input module 223;

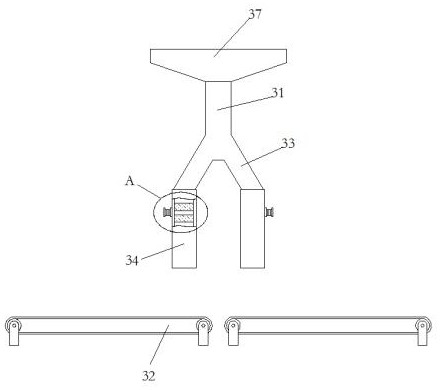

[0033] The actuator drive mechanism 3 includes a feeding cylinder 31 and two oppositely ar...

Embodiment 2

[0034] Embodiment 2 is on the basis of embodiment 1 such as figure 2As shown, its adjustment mechanism 13 includes two horizontal plates 131 fixedly connected to the side walls of the upright column 11 symmetrically. The upper end of the side horizontal plate 131 is fixedly connected with an adjusting motor 133, the output shaft of the lower end of the adjusting motor 133 runs through the surface of the horizontal plate 131 and is fixedly connected with the upper end of the rotating screw 132, and the rod wall of the rotating screw 132 is threaded with a lifting block 134, The side wall of lifting block 134 is fixedly connected with supporting plate 135, and the lower end of supporting plate 135 is fixedly provided with rotating motor 136, and the upper end output shaft of rotating motor 136 runs through the upper end of supporting plate 135 and is fixedly connected with rotating plate 137, and the rotating plate 137 One side of the upper end is fixedly connected with a U-sha...

Embodiment 3

[0035] Embodiment 3 is on the basis of embodiment 1 such as figure 2 As shown, the upper end of its support plate 135 is fixedly connected with a fixed cylinder with a cover sleeve outside the rotating plate 137, the outer wall of the rotating plate 137 is fixedly sleeved with a limiting ring plate, and the inner side wall of the fixing cylinder is provided with a ring matching the limiting ring plate. Sliding stop ring groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com