digital light processing optomechanical

A digital light processing and opto-mechanical technology, applied in optics, instruments, projection devices, etc., can solve the problems of lack of heat dissipation space, non-compliance with the pursuit of micro-projector miniature technology, low energy utilization rate, etc. area, improve the heat dissipation effect of the whole machine, and reduce the effect of mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

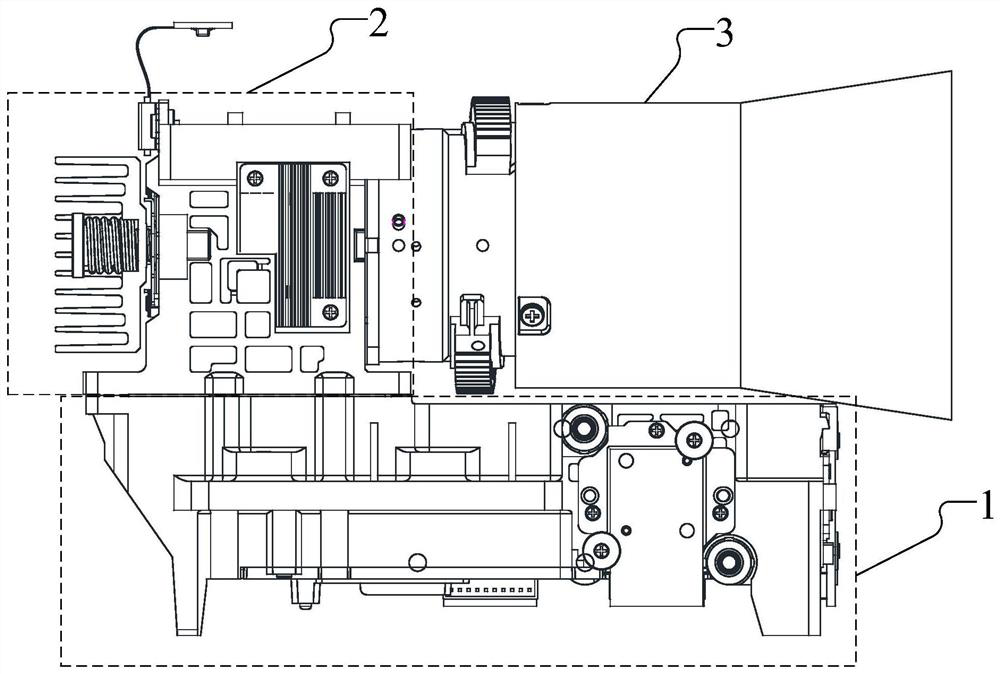

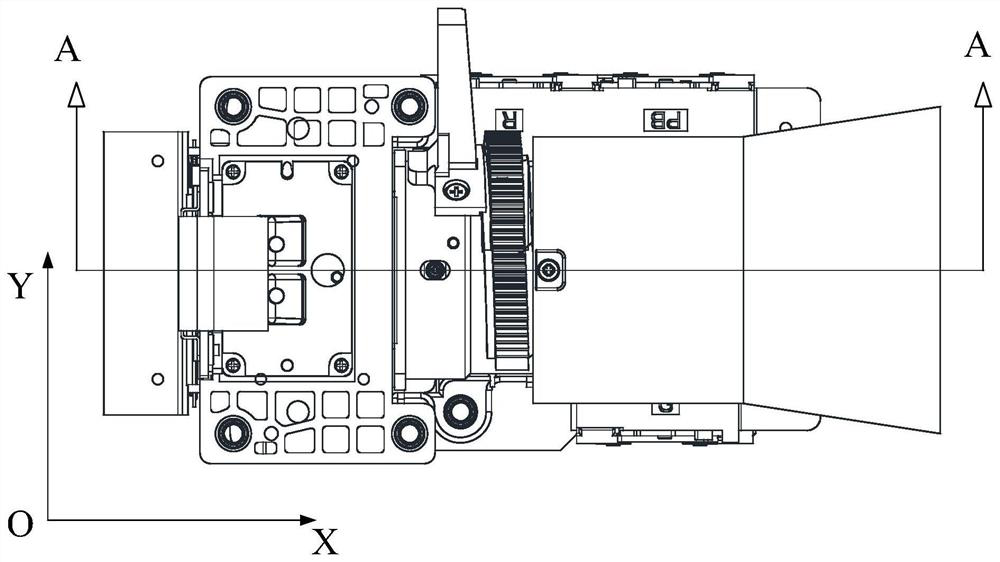

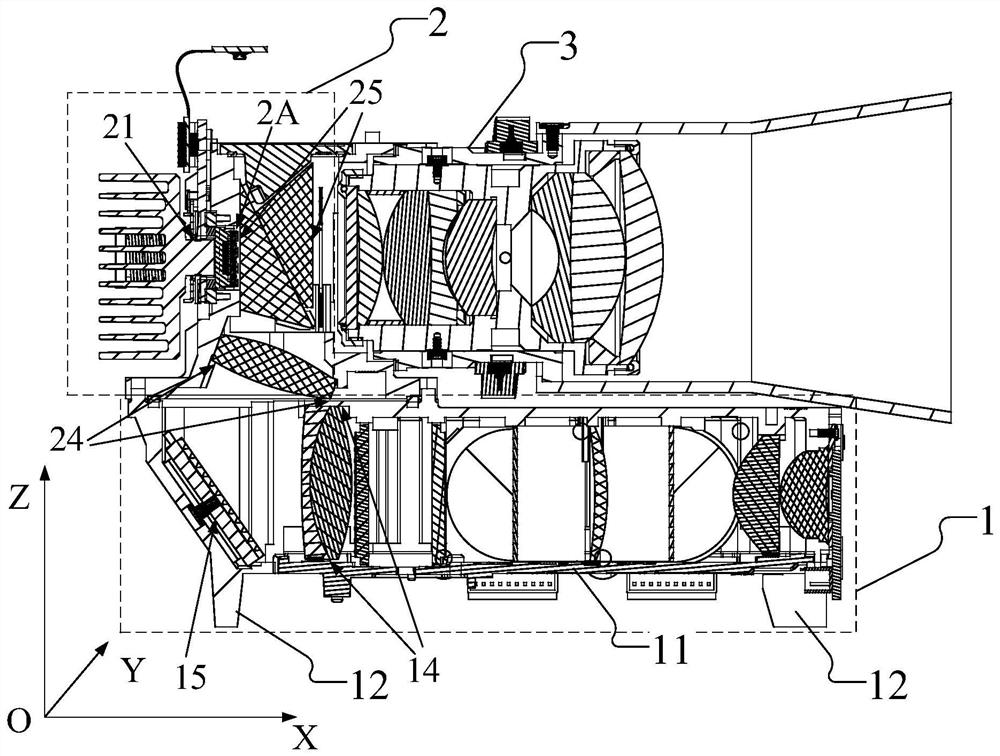

[0030] In order to improve heat dissipation, reduce the mutual influence between different optical modules, and save floor space, this embodiment discloses a digital light processing optical engine. Please refer to figure 1 , figure 2 and image 3 ,in, figure 1 A schematic diagram of the front view structure of an optical machine disclosed in this embodiment, figure 2 It is a schematic top view structure diagram of an opto-mechanical disclosed in this embodiment, image 3 disclosed in this example figure 2 Schematic diagram of the cross-sectional structure in A-A.

[0031] Please refer to figure 1 , figure 2 and image 3, the digital light processing optical machine disclosed in this embodiment includes: a first optical path module 1, an optical modulation module 2 and a second optical path module 3, which are respectively provided with a first lens group, a light modulation device and a second lens group, wherein: the first An optical path provides incident light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com