Optical machine

An optical machine and light source technology, applied in optics, instruments, projection devices, etc., can solve problems affecting the energy utilization rate of the projection system, projection uniformity, projection quality, reduced reliability of the optical machine, and reduced service life of the optical machine. Achieve the effect of facilitating independent heat dissipation, reducing the probability of short circuit, and reducing the error of optical path propagation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

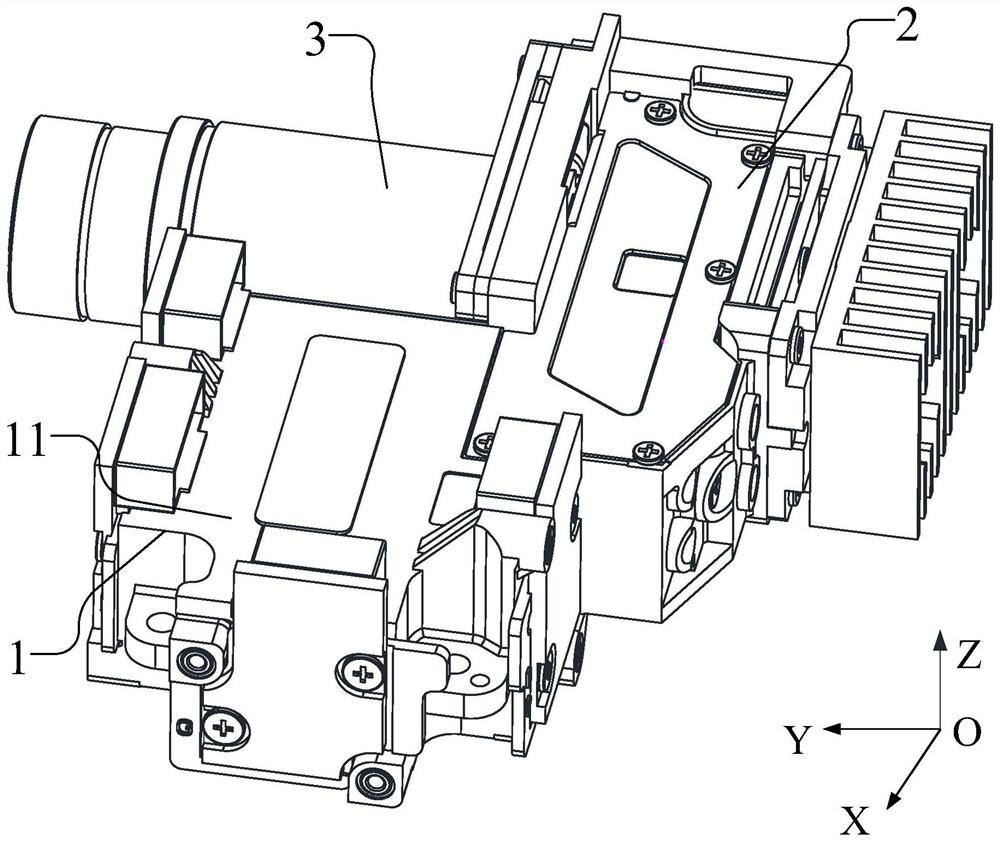

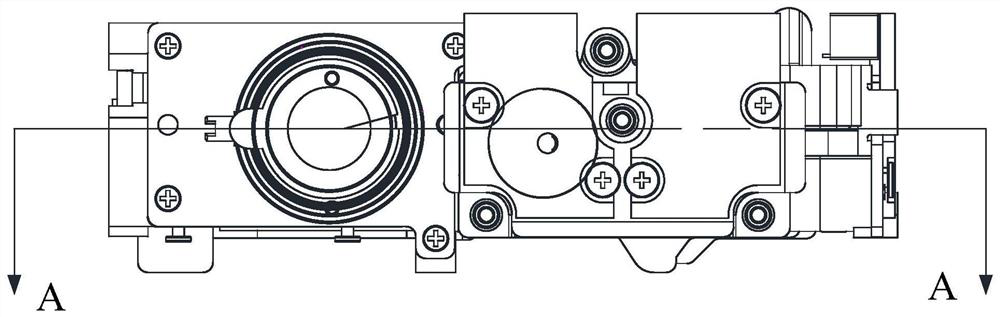

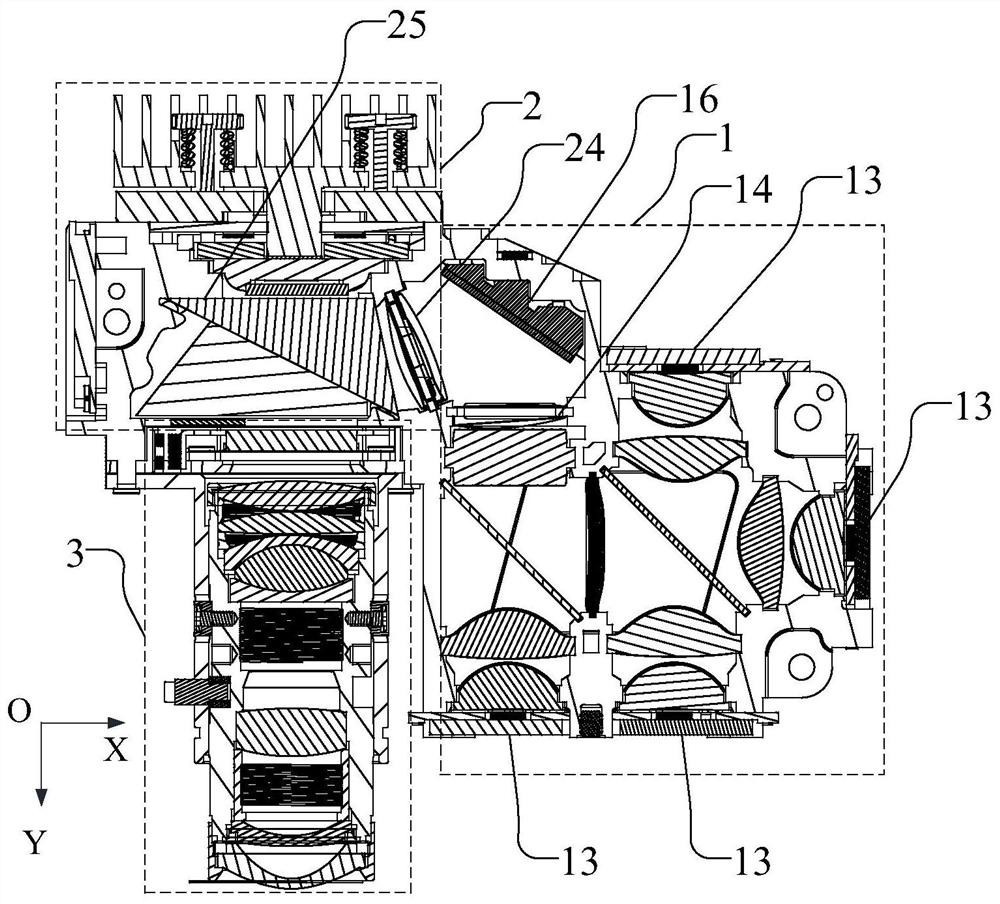

[0029] In order to ensure the reliability of the optical machine on the premise of miniaturization, this embodiment discloses an optical machine, please refer to figure 1 , figure 2 and image 3 ,in, figure 1 It is a schematic diagram of the front-view stereoscopic structure of an optical machine disclosed in this embodiment, figure 2 It is a left view structural schematic diagram of an optical machine disclosed in this embodiment, image 3 for figure 2 Schematic diagram of the A-A cross-sectional structure.

[0030] Please refer to figure 1 , figure 2 and image 3 The optical machine disclosed in this embodiment includes: a light source optical path lens group module 1, a light modulation system module 2, and a projection optical path lens group module 3, wherein the lens group of the light source optical path provides incident light to the light modulation system, and the light source can be RGB light emitting Diode; the light modulation system includes, for exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com