Device for preventing deep-buried submarine cable from being scoured

A technology for deep submarine cables and protective tubes, which is applied in the field of devices to prevent erosion of buried deep submarine cables, and can solve problems such as limited length, corrosion, aging and loosening, and influence of submarine cable transportation work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

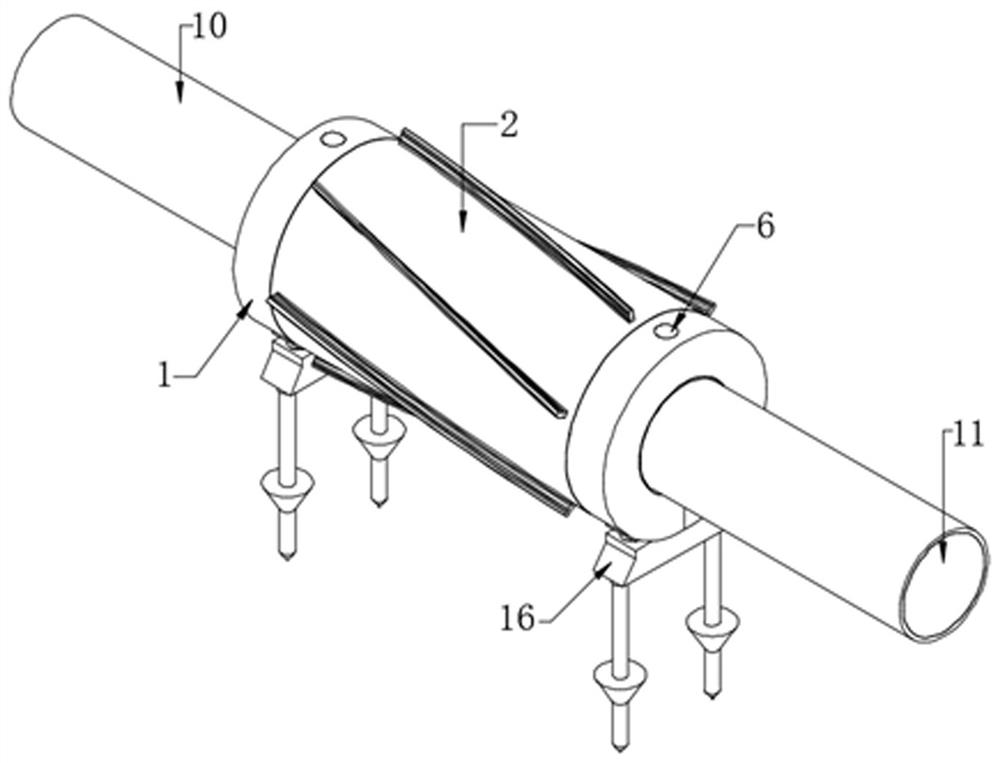

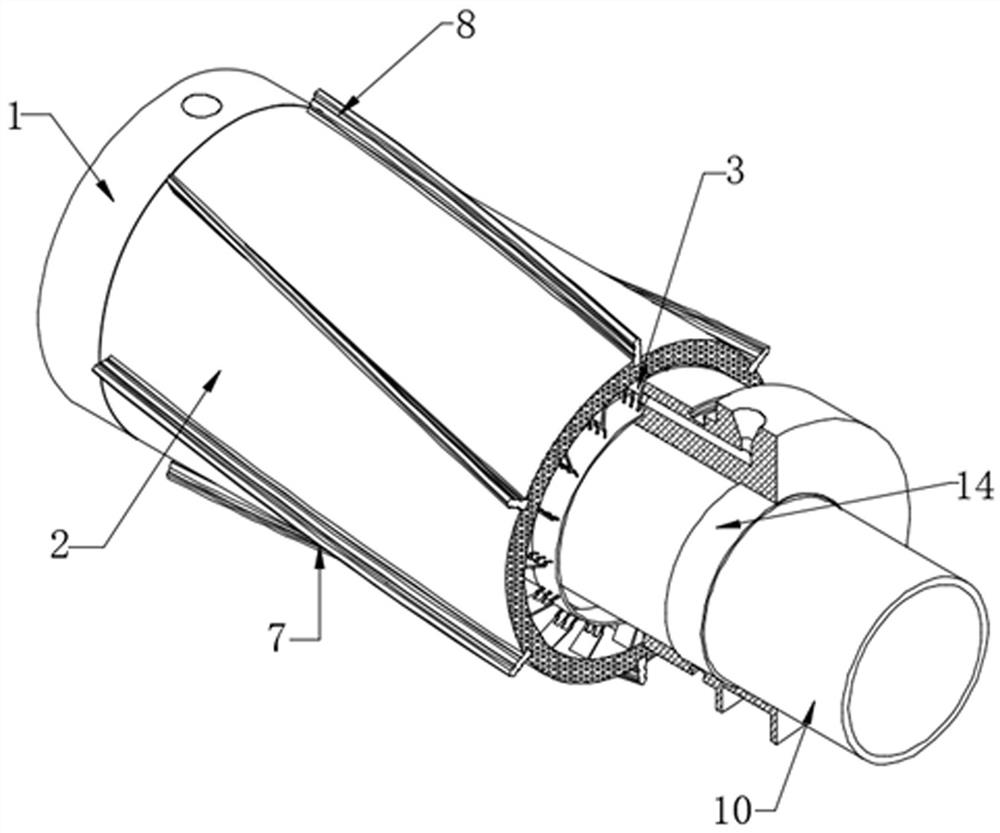

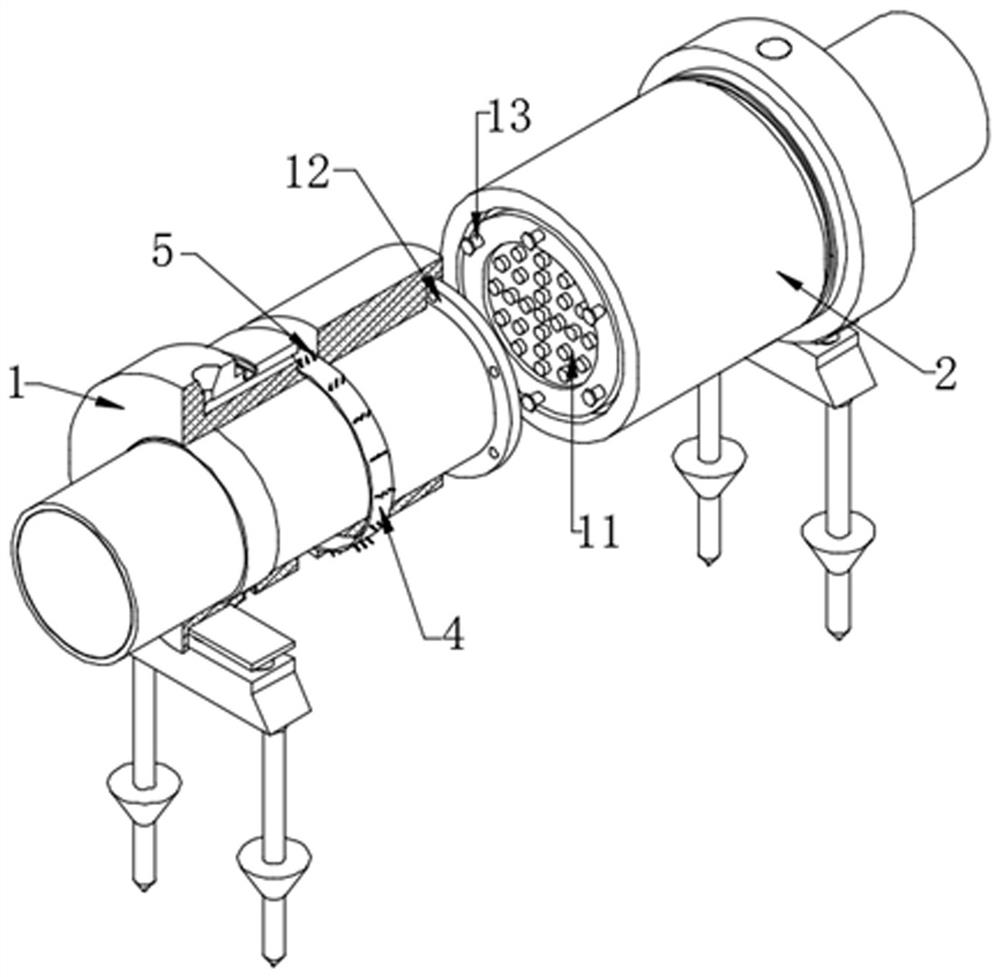

[0026] refer to Figure 1-4 , a device for preventing scouring of buried deep sea cables, comprising a protective cylinder 1, a scouring roller 2 is arranged on the outside of the protective cylinder 1, and the inner wall of the scouring roller 2 is connected with a plurality of paddles 3 by bolts, and the multiple paddles 3 are ring-shaped The outer wall of the protective tube 1 is provided with two annular grooves, and the inner wall of the annular groove is connected with a sound board 4 through bolts, and the outer wall of the sound board 4 is connected with a plurality of sounding pieces 5 through bolts, and the plurality of sounding pieces 5 are connected to each other by bolts. The surface of the sound board 4 is inclined, and the inside of the protective tube 1 is provided with a plurality of circular pipes, and the outer wall of the protective tube 1 is provided with a loudspeaker port 6, and the inside of the loudspeaker port 6 is provided with a water barrier, and th...

Embodiment 2

[0035] refer to Figure 5 , a device for preventing the erosion of buried deep sea cables. Compared with Embodiment 1, this embodiment also includes a square groove on the upper side outer wall of the base 16, and a backing plate 21 connected to the inner wall of the square groove by bolts, and the backing plate 21 The outer wall of the upper side is provided with a plurality of anti-collision protrusions 22, and the material of the anti-collision protrusions 22 is rubber

[0036]When in use, the inserting rod 19 is inserted into the soil at the bottom of the ocean, and the device is fixed in the ocean as a whole. After installation, the flow of water inside the ocean is blocked by the resistance plate 7, and the kinetic energy in the flow of the water body is converted into the energy of the resistance plate 7. Thrust force, the washing roller 2 rotates outside the protective cylinder 1. During the rotation of the washing roller 2, a plurality of plectrums 3 are constantly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com