Emulsified lubricating oil negative pressure dehydration poking type membrane breaking system and membrane breaking method thereof

A negative pressure dehydration and lubricating oil technology, which is applied in the field of lubricating oil processing, can solve problems such as residue, oil film thickness, and affecting the dehydration effect of emulsified lubricating oil, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

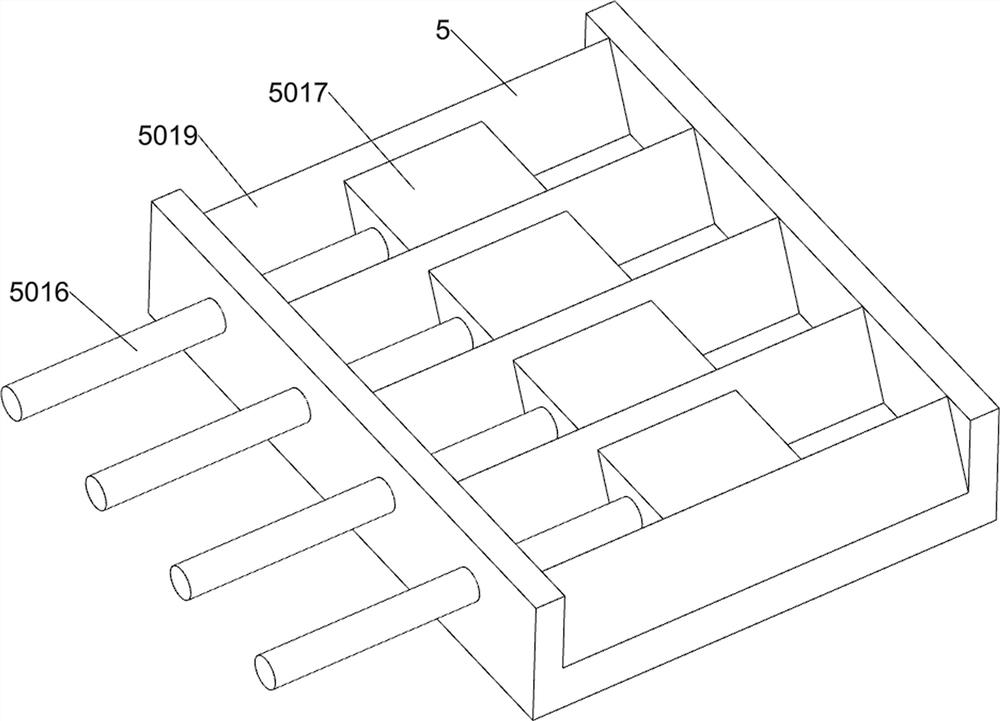

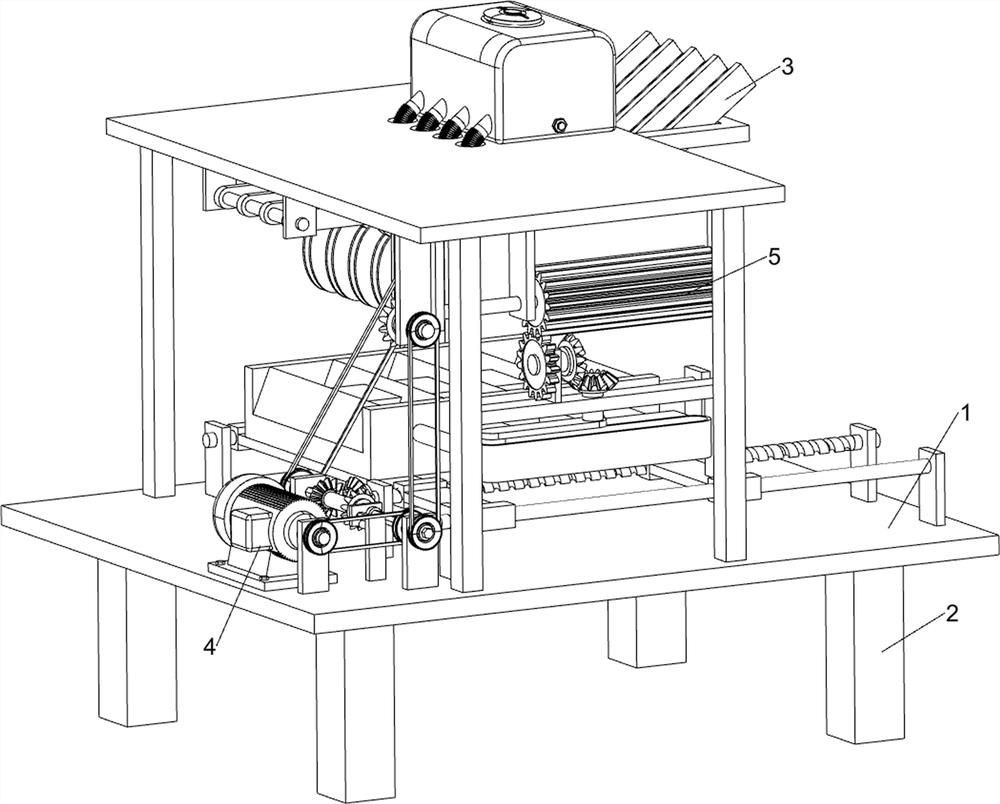

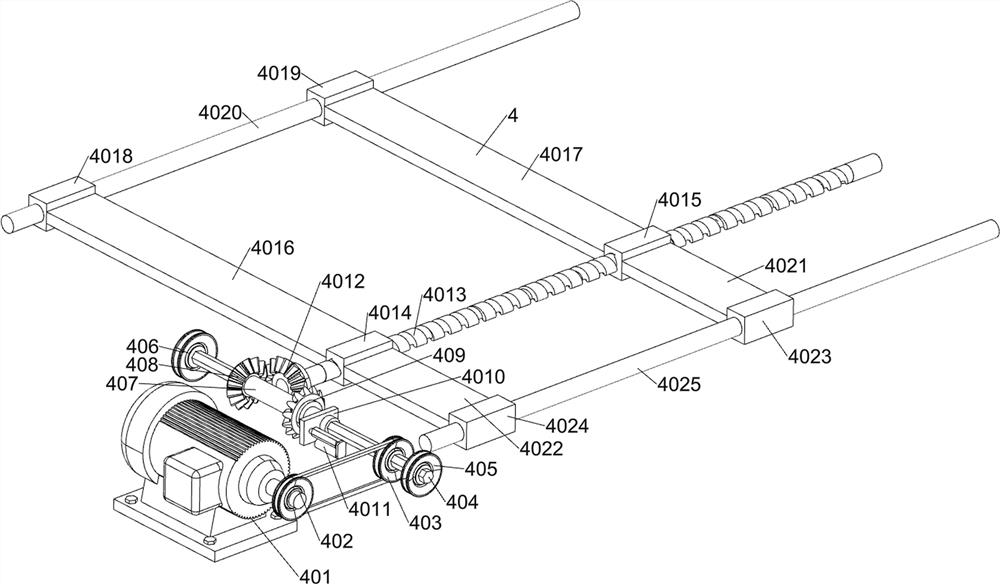

[0037] A negative pressure dehydration poking membrane breaking system for emulsified lubricating oil, such as Figure 1-10 As shown, it includes a working frame plate 1, a supporting base 2, a stamping film water absorption system 3, a transfer transmission system 4 and a grinding film system 5; a group of supporting bases 2 are arranged at the four corners below the working frame plate 1; the working frame plate 1 and the stamping film The film water absorption system 3 is connected; the work frame plate 1 is connected with the transfer transmission system 4; the work frame plate 1 is connected with the grinding film system 5; the stamp film water absorption system 3 is connected with the transfer transmission system 4; The membrane system 5 is connected.

[0038] Working process: When using this device, place the device horizontally in a workshop in a negative pressure environment, fix it through the work frame plate 1 and the support base 2, turn on the power, and the oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com