Grinding jig, grinding equipment and grinding method

A fixture and equipment technology, which is applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of low product grinding efficiency, low yield rate of polished products, and high scrap cost, so as to improve grinding efficiency and good grinding quality. High efficiency, simple structure, and the effect of improving the grinding yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

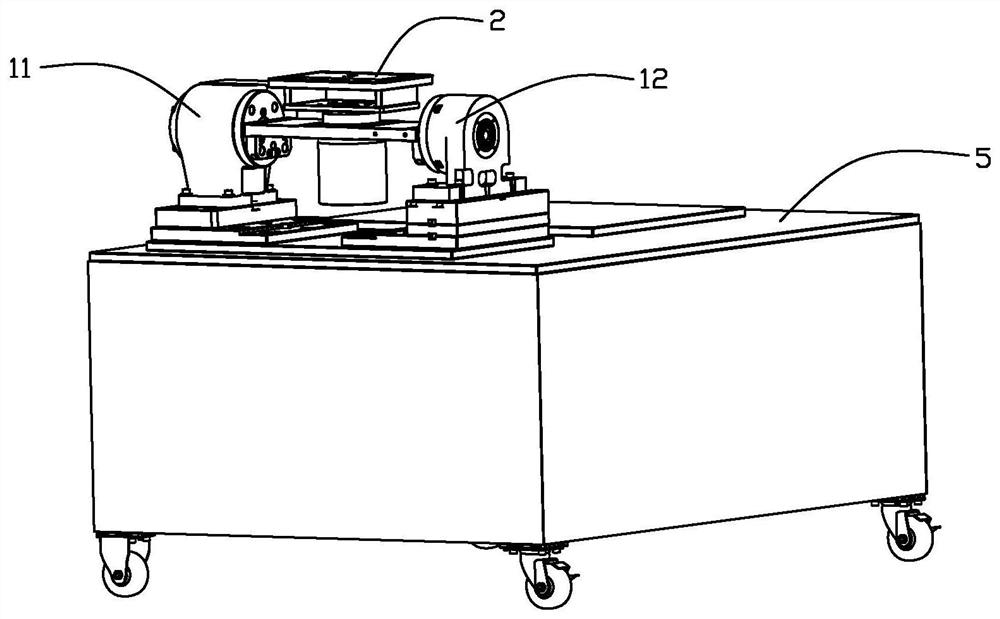

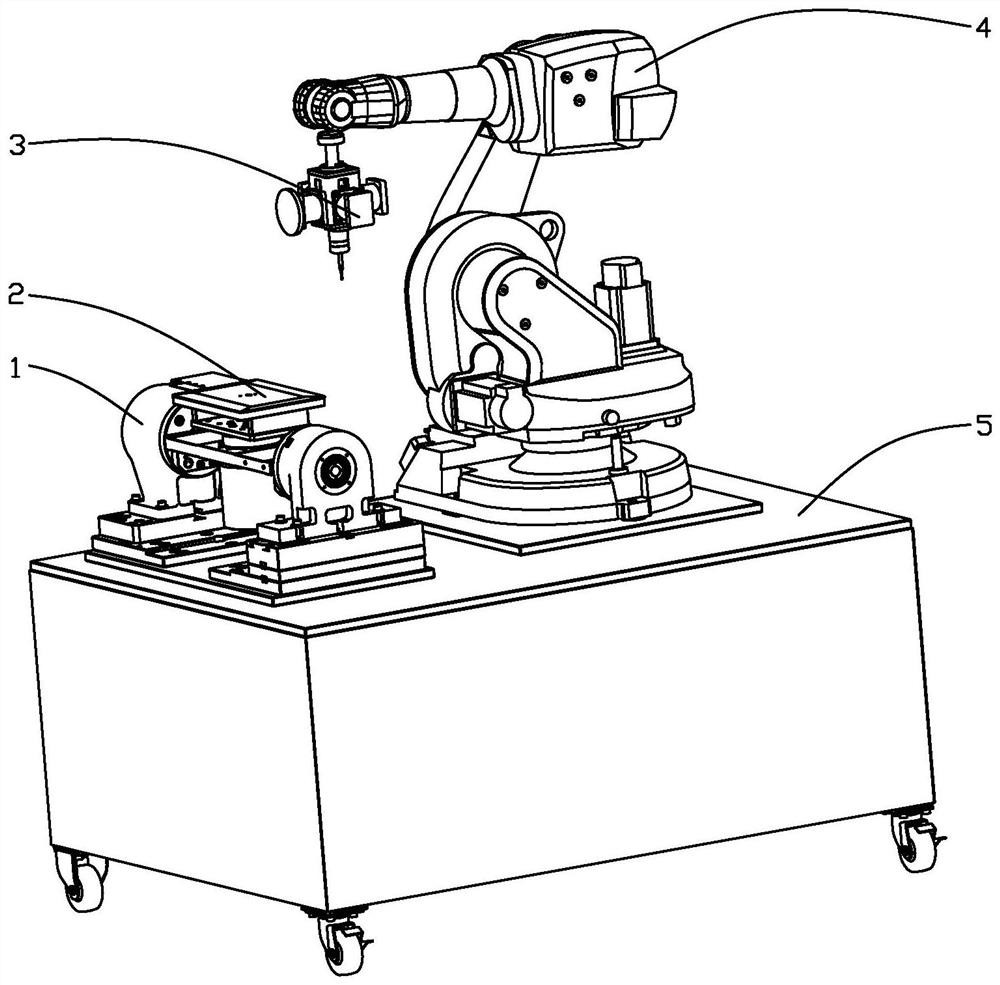

[0038] Embodiment 1: as figure 1 and Figure 5 As shown, the present embodiment provides a grinding jig 1, including a worktable 5, a first rotating device disposed on the worktable 5, and a second rotating device disposed on the first rotating device.

[0039] The first rotating device includes a rotating support, a first driving device (not shown), a first rotating shaft arranged on the rotating support and electrically connected to the first driving device, and fixed to the The supporting plate 111 on the first rotating shaft; the first rotating shaft can drive the supporting plate 111 to rotate; the first driving device is used to drive the first rotating shaft.

[0040] The rotating support includes a driving end support 11 and a follower end support 12 ; the driving end support 11 and the follower end support 12 are respectively fixedly connected to the workbench 5 through a fixing plate 113 . The first rotating shaft 114 of the driving end is provided on the support 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com