Textile fabric cutting device

A textile cloth and cutting device technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problem of low laying efficiency and achieve the effect of improving laying and cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

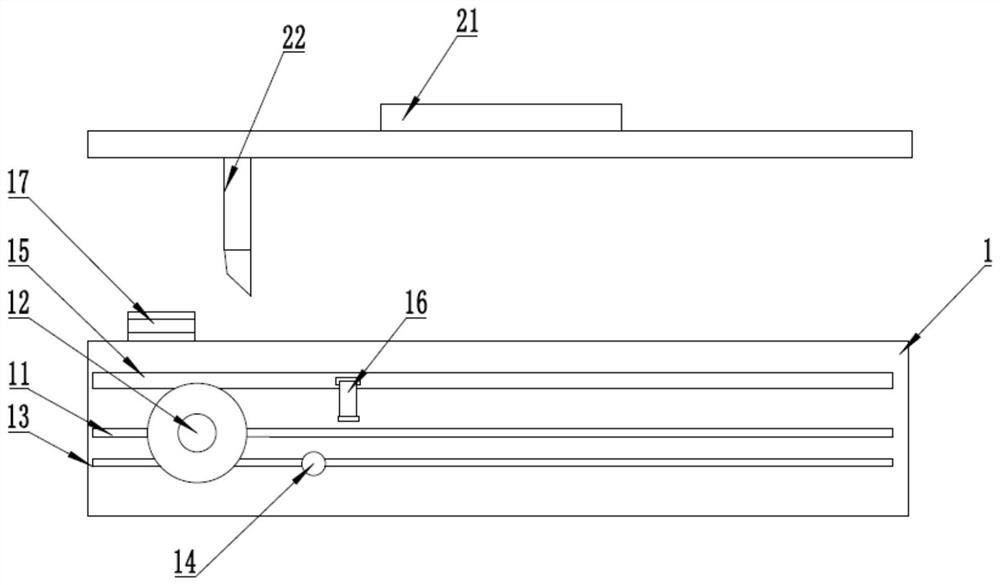

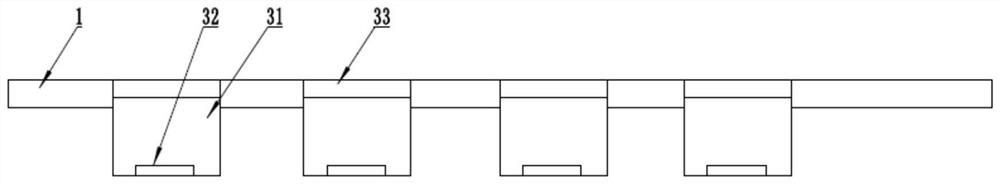

Method used

Image

Examples

Embodiment approach

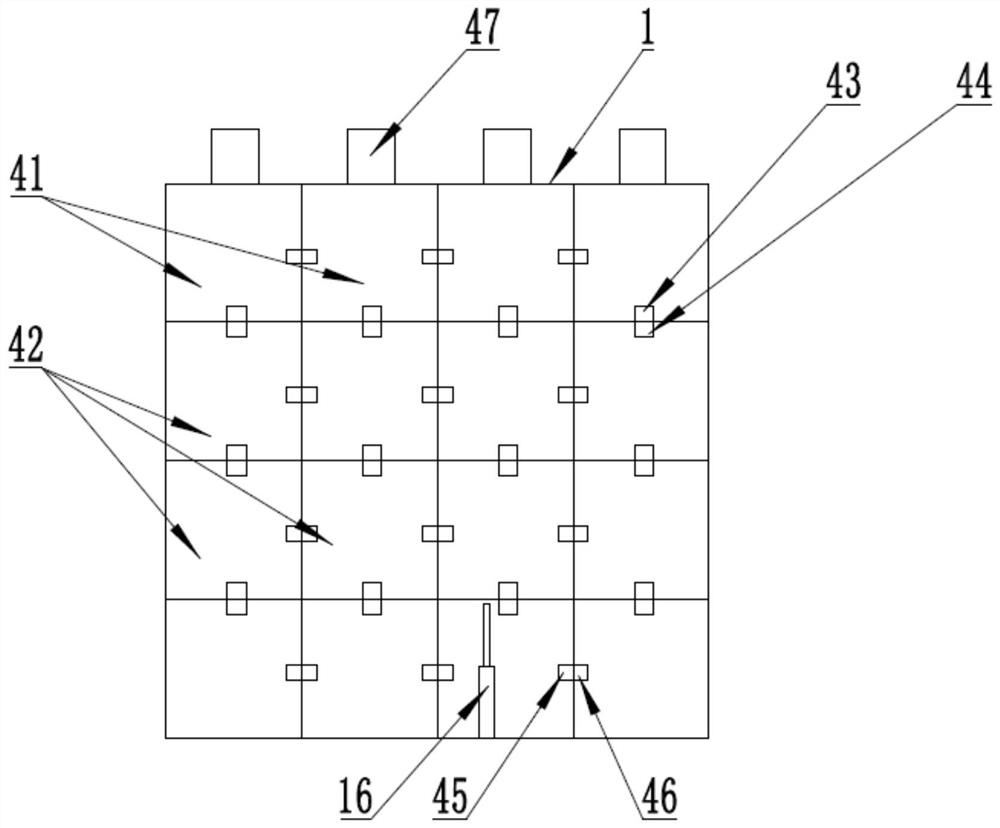

[0030] As an embodiment, the device also includes a collection mechanism, then the placement table 1 includes a plurality of first boards 41 arranged on one side of the placement table 1, and also includes a plurality of second boards 41 arranged on the side of the first board 41. Plate body 42, the width of the first plate body 41 is the same as that of the second plate body 42;

[0031] A plurality of rotating motors 47 are installed on the edge of the placing table 1, which are respectively connected with each first plate body 41 to drive each first plate body 41 to rotate. The first plate body 41 and the second plate body 42 are arranged on the long axis side. A first buckle 43 is provided, a first slot 44 matching the first buckle 43 is provided on the other side of the major axis, and a first board body 41 and a second board body 42 are provided with a The second buckle 45 is provided with a second slot 46 matching the second buckle 45 on the other side of the short axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com