Blade structure resistance increasing device and method for horizontal-axis wind generating set

A technology for wind turbines and blade structures, applied in the direction of wind engines, wind engines consistent with the wind direction, wind engine control, etc., can solve problems such as the influence of blades on safe operation, increase the damping of blade vibration structures, save time and Cost, effect of improving buckling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

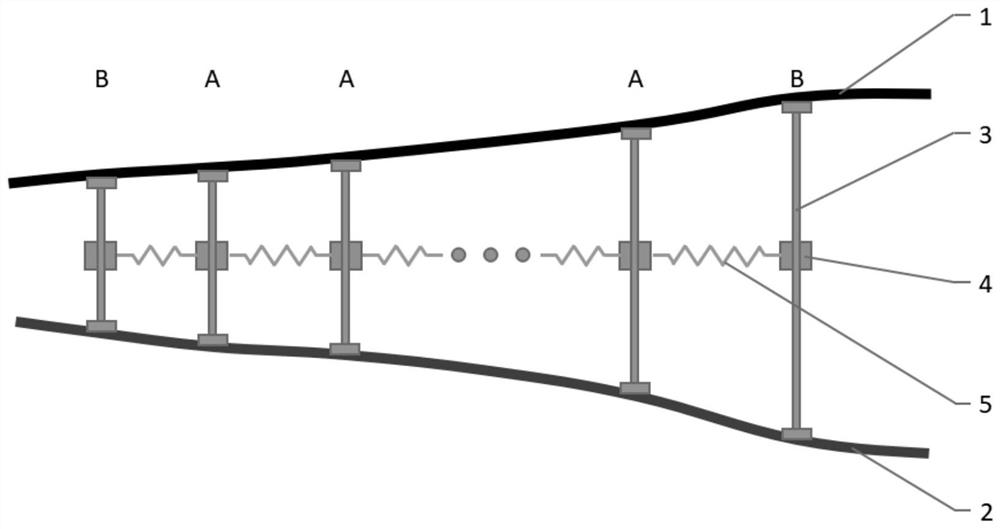

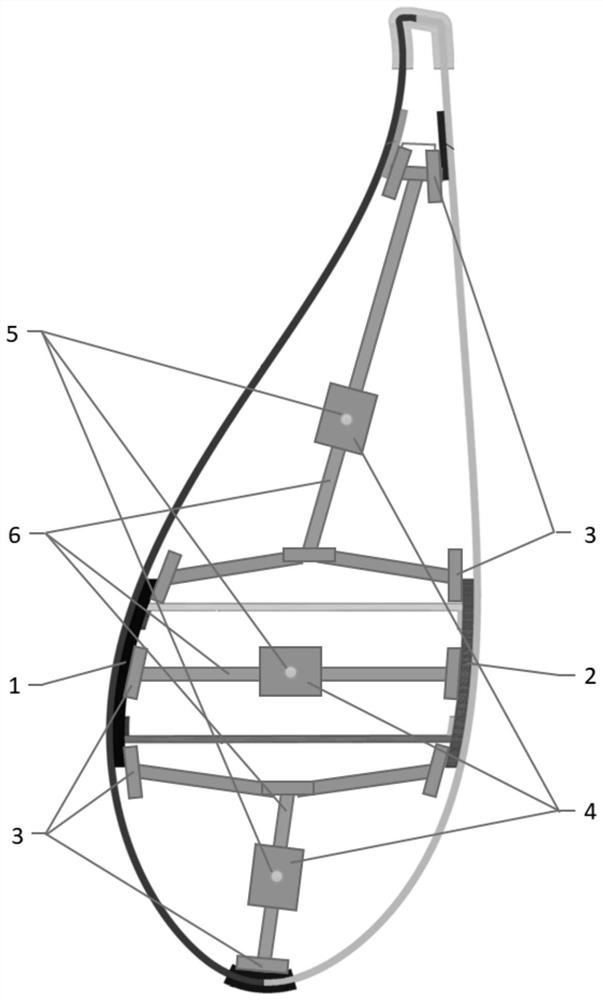

[0040] Such as figure 1 , figure 2 As shown, the present invention provides a blade structure resistance device for a horizontal axis wind power generating set. There are multiple The main body of the blade structure damping device is used to increase the damping of the blade vibration structure in the blade flapping direction and the shimmy direction.

[0041] The blade structure resistance device body includes a restoring force mass block power unit and an elastic connection structure 5, wherein the restoring force mass block power unit is arranged in multiple groups, arranged in the same cavity along the spanwise direction of the blade, and two adjacent return The force mass power units are connected to each other by an elastic connection structure 5 .

[0042] The restoring force mass block power unit includes a supporting structure 3, a mass block 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com