Blade power increasing system with trailing edge being thickened

A blade and blunt trailing edge technology, which is applied in the field of blade power augmentation system, can solve problems such as the increase of drag coefficient, and achieve the effects of reducing drag coefficient, improving lift-drag coefficient, and improving trailing edge shedding vortex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] In order to clearly understand the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further elaborated below in conjunction with the accompanying drawings.

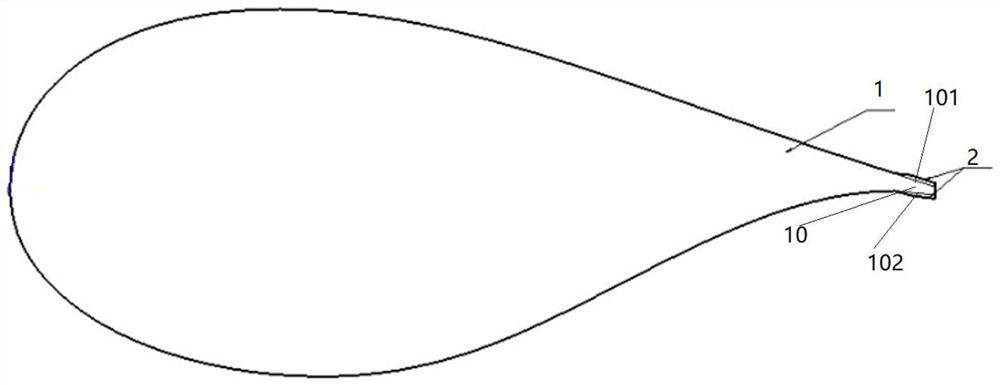

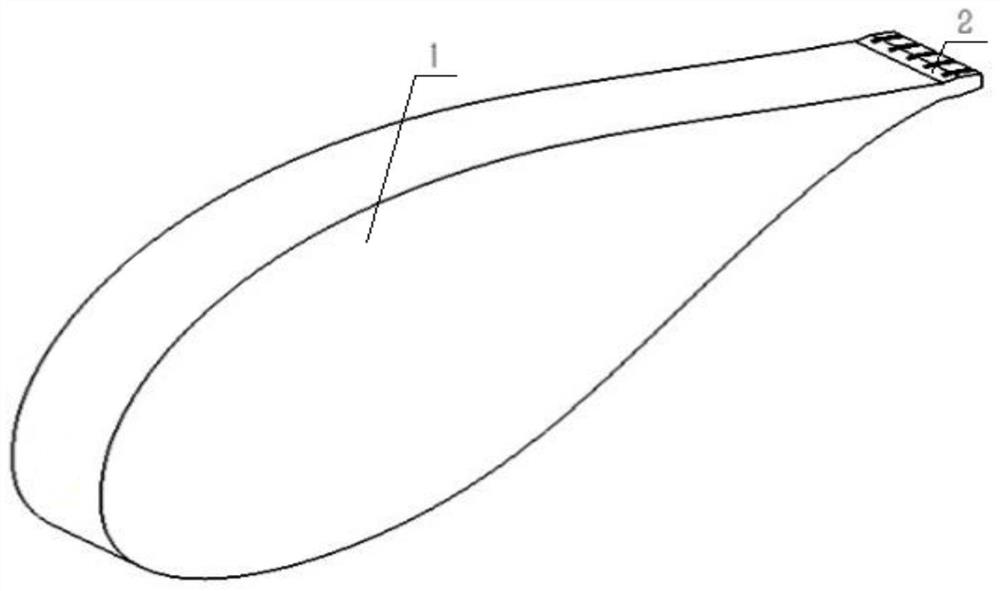

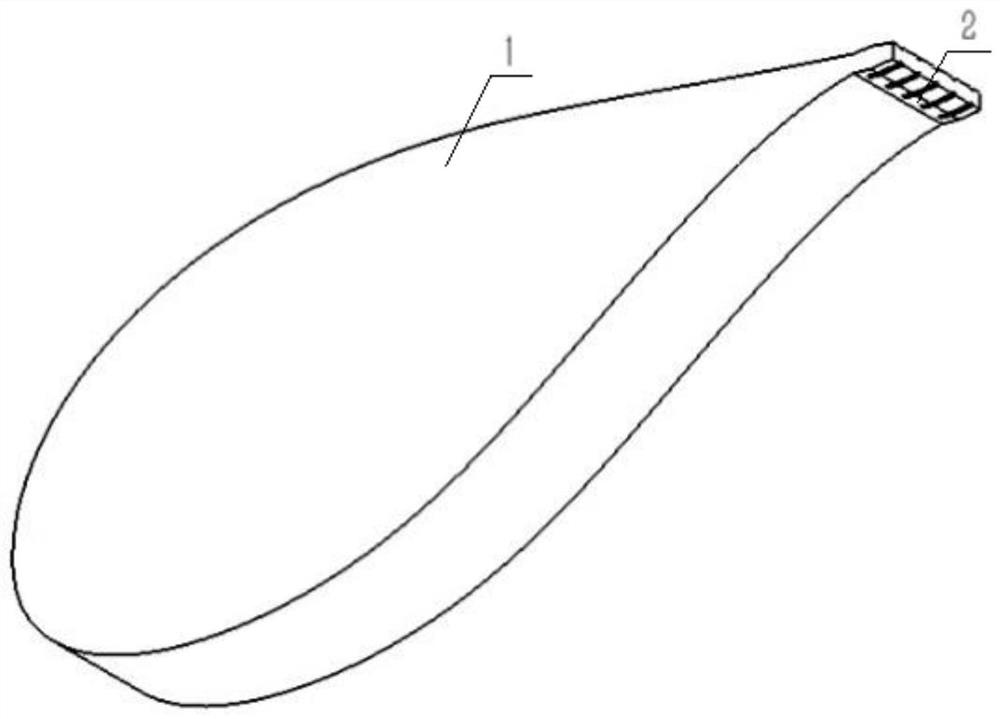

[0042] see Figure 1 to Figure 3 As shown, the present invention discloses a blade power booster system with a thickened trailing edge, which includes a blade airfoil main body 1 and a power booster device 2, the trailing edge part of the blade airfoil main body 1 is a blunt trailing edge 10 with a thickness, and A power booster 2 is provided on at least one of the suction surface 101 or the pressure surface 102 of the blunt trailing edge 10 of the blade airfoil main body 1 . The power booster 2 is wedge-shaped in cross section and includes a plurality of grooves 20 .

Embodiment 1

[0044] Such as Figure 4-8 As shown, as a preferred embodiment, in a blade power augmentation system with thickened trailing edge in the embodiment of the present invention, the blade airfoil main body 1 adopts DU00-W401 airfoil, the chord length c=1000mm, the width is 100mm, blunt The thickness of the trailing edge 10 is 10mm, the power booster 2 is installed on the pressure surface 102 of the blade airfoil main body 1, the contact surface between the power booster 2 and the blade airfoil main body 1 is a follow-up surface, the length X=45mm, and the thickness d= 3mm, the length L0 of the surface 21 in contact with the airflow in the power booster 2 =25mm, the wedge angle β=10° away from the trailing edge of the blade airfoil main body 1, the power booster 2 has 6 grooves 20 on the contact surface with the airflow, The distance between the grooves 20 is D=16 mm, the depth of the grooves 20 is 2 mm, and the opening direction of the grooves is θ=90°.

[0045] Use CFD to calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com