Test method for simulating real vehicle cold start emission test by using engine bench

An engine bench and test method technology, which is applied in the direction of engine testing, internal combustion engine testing, machine/structural component testing, etc. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the purpose, structure and function of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings.

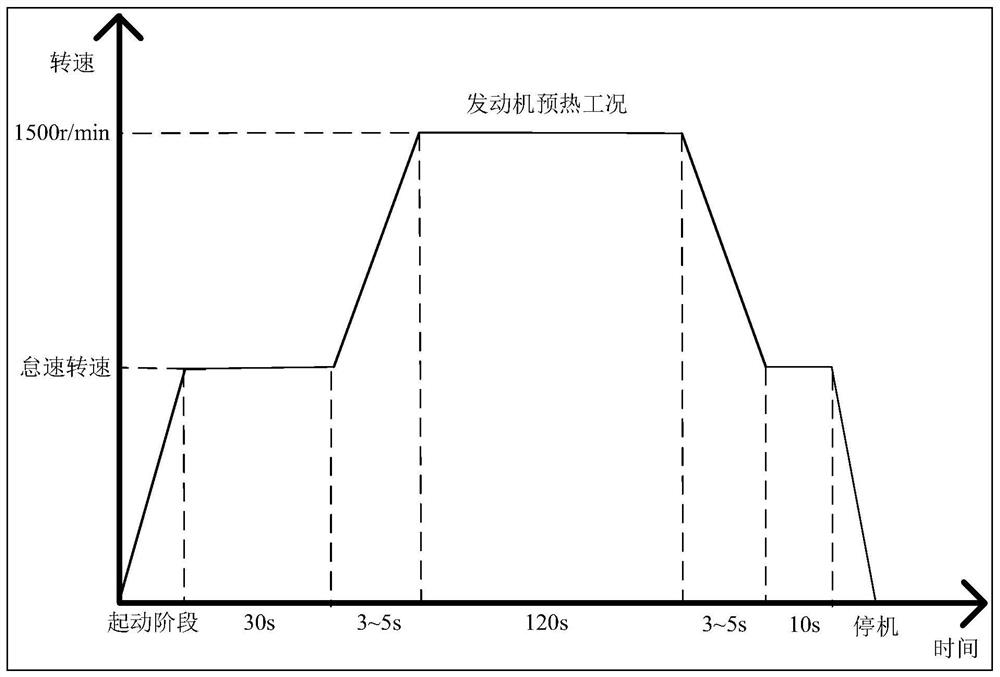

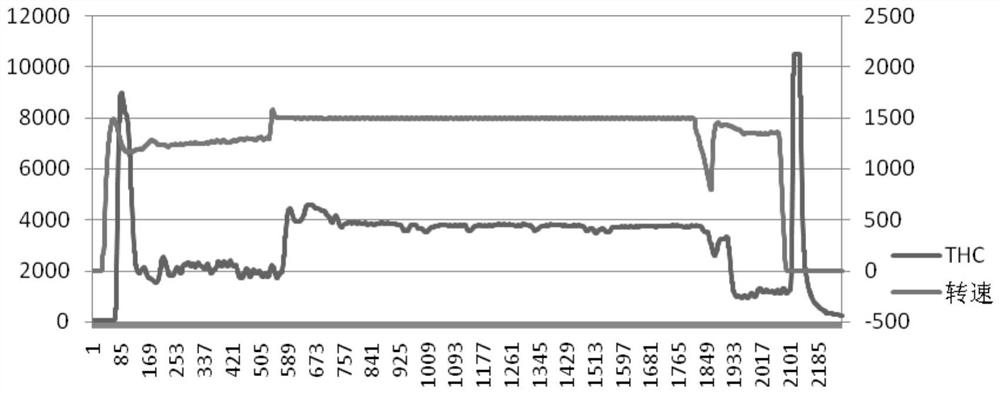

[0014] Apply the engine bench to simulate the real vehicle cold start emission test method, reduce the engine oil temperature and coolant temperature to room temperature, connect the emission direct mining equipment and air-fuel ratio measurement equipment, and carry out the cold start test. After the engine is successfully started, it enters the idling condition After a period of time, increase the speed and torque, and warm up the engine. During the test, parameters such as original emission and particulate matter quantity are collected (i.e. data recording and analysis). Through the test data curve, the emission performance of the current engine state can be determined. .

[0015] to combine figure 1 To further explain this optimization plan:

[0016] 1. Preparato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com