Method for testing dielectric property of ceramic material and application of method

A technology of ceramic materials and dielectric properties, applied in the field of functional materials testing, can solve the problems of long cycle time, complex production process of final products, difficulty in meeting the testing requirements of ceramic filling materials, etc., and achieve short preparation time and accurate results of dielectric properties Reliable, stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

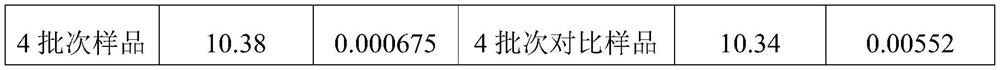

Examples

Embodiment 1

[0034] The present embodiment provides a method for testing the dielectric properties of ceramic powder, and the specific steps are as follows:

[0035] S1. The mass ratio of the dispersion is, polyethylene oxide: ethanol: water = 0.03: 2: 100, and the viscosity of the dispersion is 50 mP.S. To the dispersion (20 g), add titanium dioxide powder (40 g, particle size 20 μm, shape spherical shape, impurity content <1wt%), after stirring uniformly, add PTFE dispersion emulsion (30g, solid content is 60%) and stir uniformly.

[0036] S2. The slurry obtained in S1 is placed in an oven at 100° C., dehydrated for 15 minutes, and then taken out and cooled.

[0037] S3, put the sample obtained in S2 into a calender for calendering, the calendering temperature is 25° C., the calendering speed is 10r / min, the number of calendering is 16 times, and the calendering thickness is 0.6mm.

[0038] S4, put the sample obtained in S3 into the oven for debinding, the debinding temperature is 170°C...

Embodiment 2

[0043] The difference between the method for testing the dielectric properties of the ceramic powder provided in this example is that the ceramic powder used in this example is an angular titanium dioxide powder with a particle size of 3 μm.

[0044] After testing, at room temperature, the density of the sample is 2.91g / cm 3 , the dielectric constant at 6.5GHz is 11.45, and the dielectric loss is 0.00103.

Embodiment 3

[0046] The difference between the test method provided in this example and Example 1 is that the ceramic powder used in this example is spherical strontium titanate powder with equal mass and particle size of 15 μm.

[0047] After testing, at room temperature, the density of the sample is 3.32g / cm 3, the dielectric constant at 6.5GHz is 16.45, and the dielectric loss is 0.0082.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com