Thermoplastic elastomer accelerated creep test method

A thermoplastic elastomer, accelerated creep technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of inability to accurately obtain the shift factor, error in experimental results, long test time, etc., to shorten the test time. , the effect of overcoming errors and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

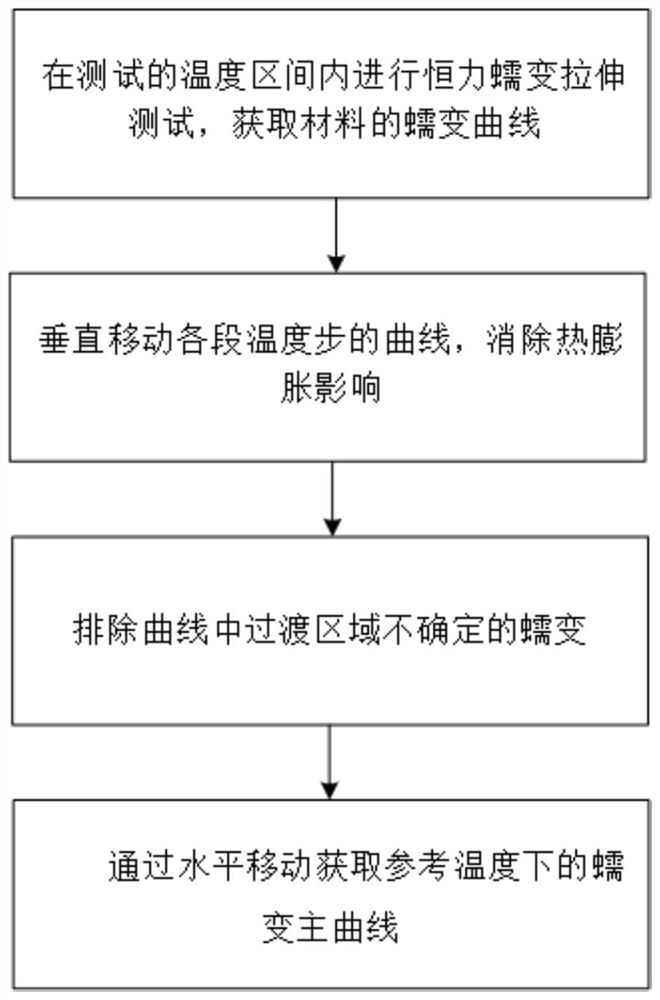

[0030] The time-temperature equivalence principle can be used to observe the creep behavior for a long time by increasing the temperature. The Boltzmann superposition principle believes that the deformation of the sample is a function of the load history. When multiple loads act on the polymer together, each load is independent. , can be superimposed on each other. Based on the above principles, multiple samples can be tested at each temperature, and a single sample can be used instead of a step temperature, and the number of test samples can be reduced by increasing the test conditions. Based on this thinking, the present invention provides a kind of thermoplastic elastomer accelerated creep test method, and this method comprises the following steps:

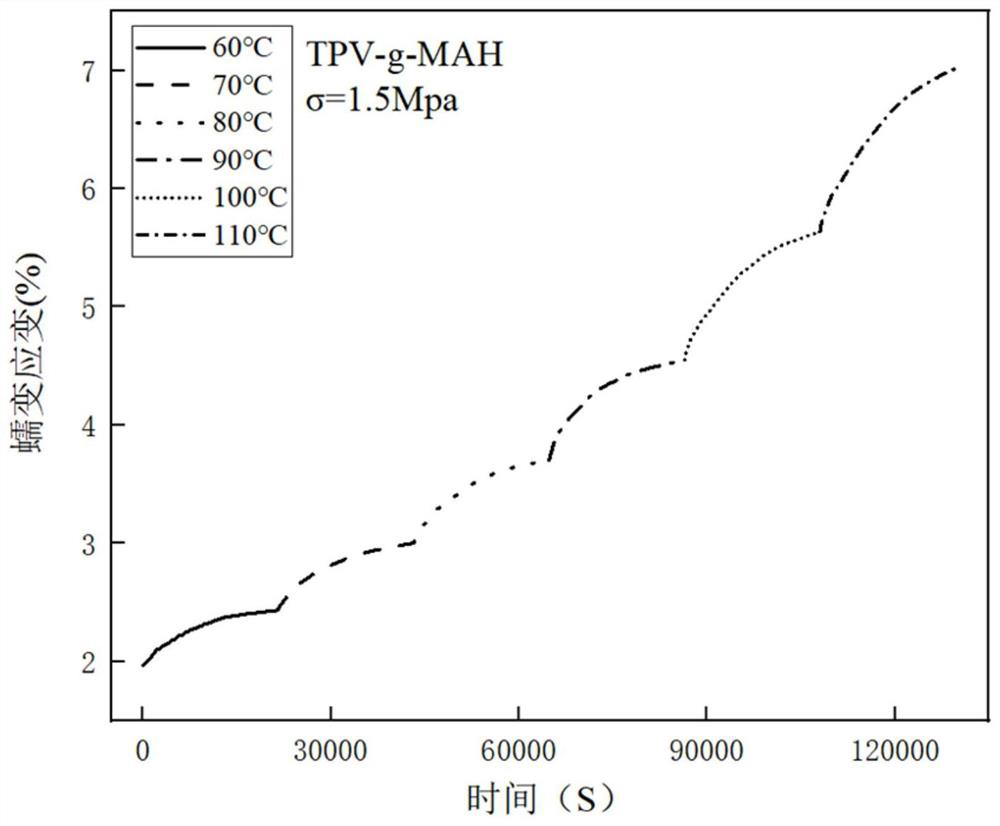

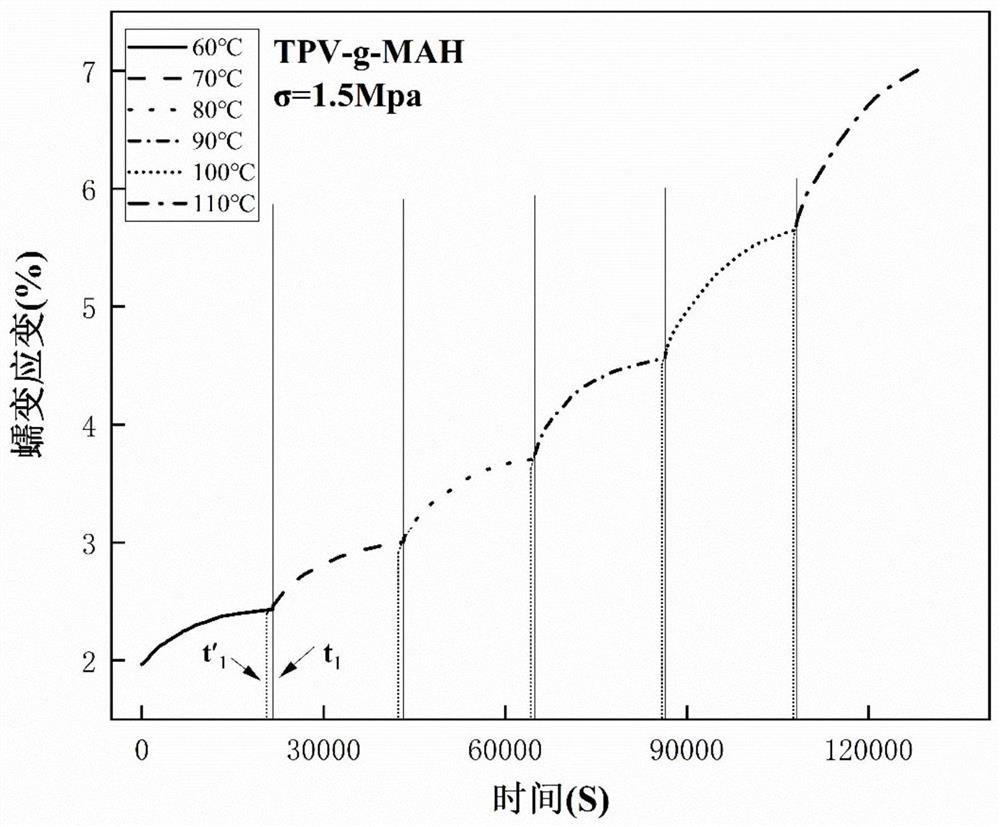

[0031] Step 1: Perform a constant force creep tensile test within the temperature range of the test to obtain a creep curve of the material.

[0032] Among them, the temperature range of the creep tensile test is usually the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com