Visual grain monitoring terminal convenient to clean

A monitoring terminal and visual technology, which can be used in measuring devices, testing plant materials, and material analysis by optical means, which can solve problems such as troublesome and difficult cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

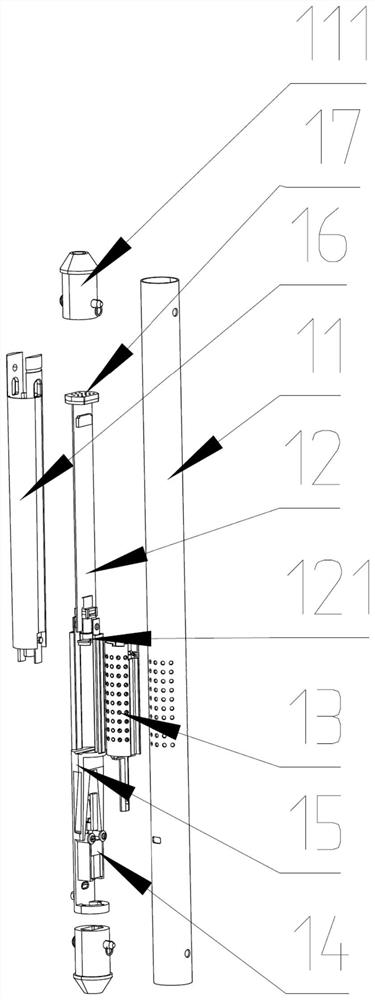

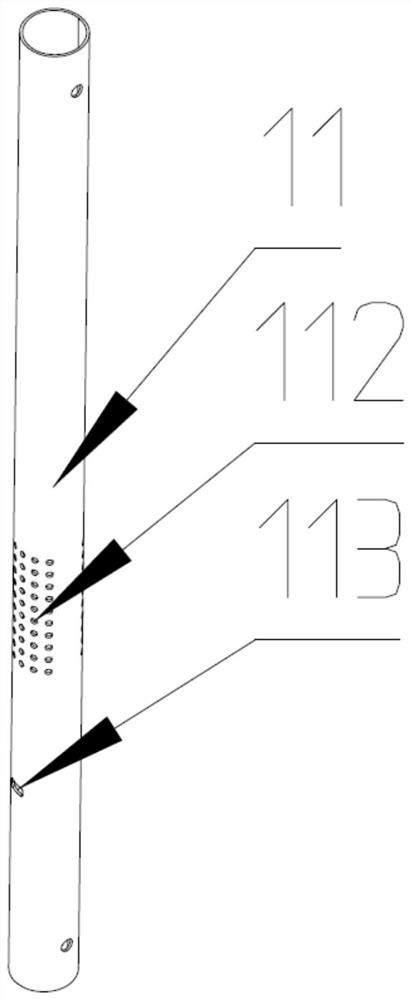

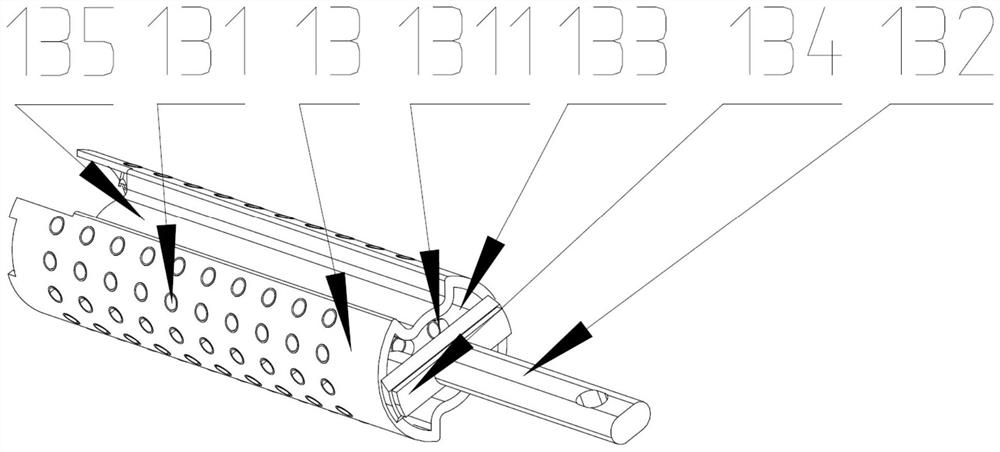

[0039] see Figure 1-6 , a visual grain monitoring terminal that is easy to clean, including a housing 11; preferably, the housing 11 is made of stainless steel tube and has a cylindrical shape; both ends of the housing 11 are open, and both ends are provided with sealing ends The plug 111, the end plug 111 is connected with the shell 11 through the positioning pin 1111; the end plug 111 is provided with a connecting hole 1112; the shell 11 is provided with a circuit board 12 which plays a core control role, and various required components are welded on the circuit board 12. Electric component; Described circuit board 12 is connected with monitoring device, and described monitoring device comprises camera 121, temperature sensor and humidity sensor etc.; The side of described camera 121 is also provided with supplementary light; The region that camera 121 illuminates is provided with for The pest collecting tube 13 is stored; the pest collecting tube 13 is provided with a firs...

Embodiment 2

[0044] Embodiment 2 is a further description of Embodiment 1, and the same parts will not be repeated here, please refer to Figure 1-6 , the base 15 adopts a cylindrical shape, the diameter of the base 15 is slightly smaller than the inner diameter of the housing 11, and an assembly gap of 0.5 mm is left in the design; the actuator 14 is a telescopic motor or an electric push rod, preferably, A telescopic motor is used as the actuator 14; the base 15 is provided with an installation groove 154 for placing the actuator 14; above the installation groove 154, there is a movement groove 155 for placing the output end of the actuator 14; the installation hole 151 It is arranged above the movement slot 155; the connecting rod 132 is connected to the output end of the actuator 14 through the installation hole 151, and the connection method can be plug-in.

[0045] The both sides of mounting hole 151 are provided with leaking insect passage 152; Namely the leaking insect passage 152 ...

Embodiment 3

[0048] The third embodiment is a further improvement to the second embodiment, and the same parts will not be repeated here, please refer to Figure 1-6 The insect collecting pipe 13 is also cylindrical, and its diameter is slightly equal to the inner diameter of the shell 11, and an assembly gap of 0.5 mm is left; the left and right sides of the insect collecting pipe 13 are provided with chute 135 for limiting; The base 15 top is provided with the supporting frame 156 that cooperates with described chute 135, and described supporting frame 156 is altogether two, is respectively arranged correspondingly with the chute 135 on the left and right sides of insect collecting pipe 13; 156 engages with the corresponding chute 135 to further limit the moving direction of the insect collecting tube 13 .

[0049] Because the insect collecting pipe 13 is also cylindrical, its diameter is slightly equal to the inner diameter of the shell 11; The pests within 13 can all be discharged wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com