Device for unloading and bagging grinding body of ball mill

A ball mill and grinding body technology, applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of unfavorable use, large manpower consumption, high time cost, etc., and achieve the effect of improving the use effect, efficient operation, and simple and reliable device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

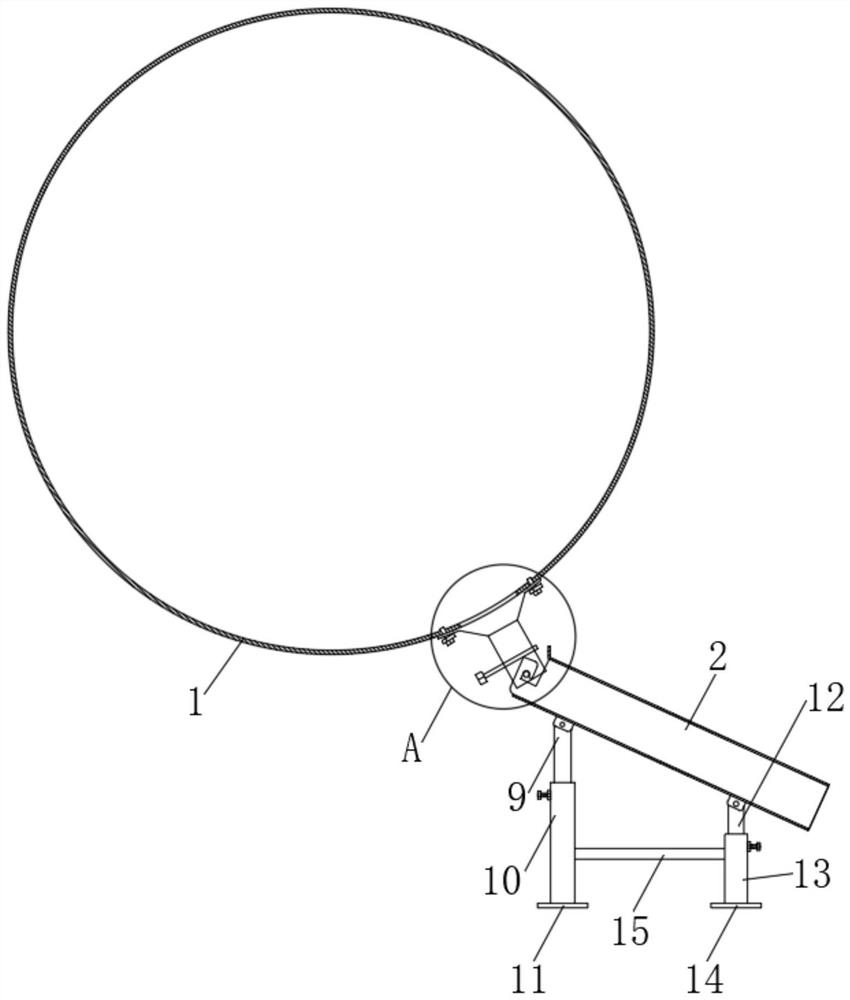

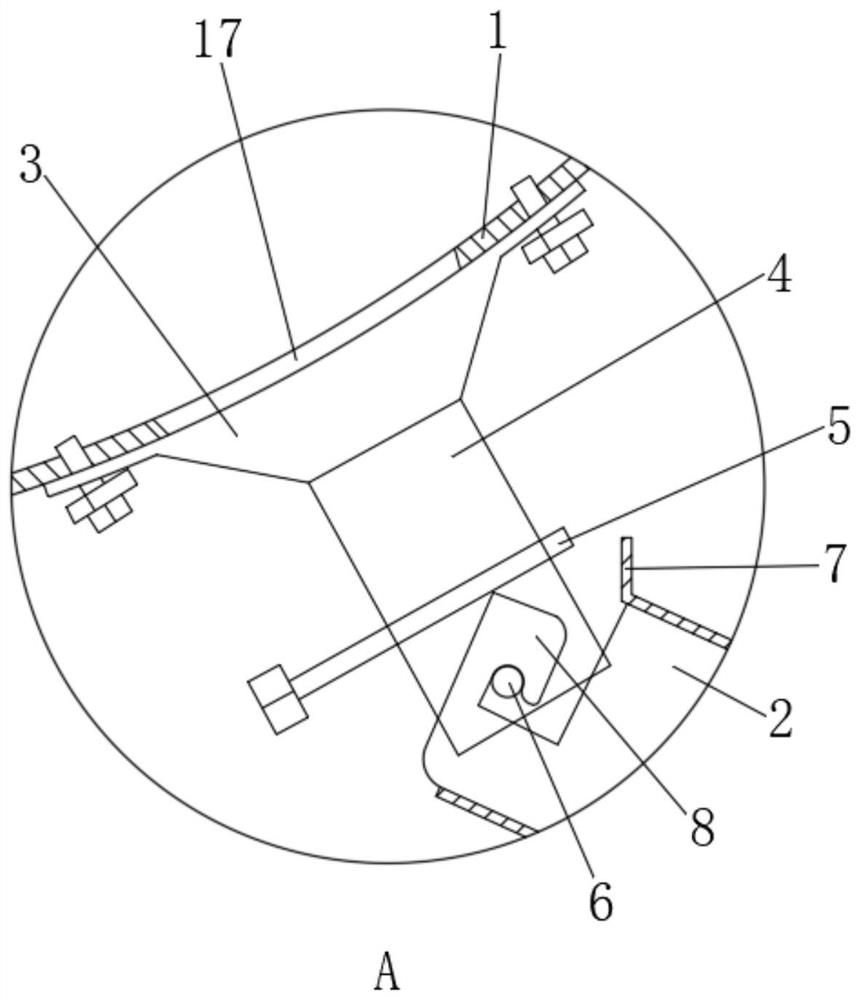

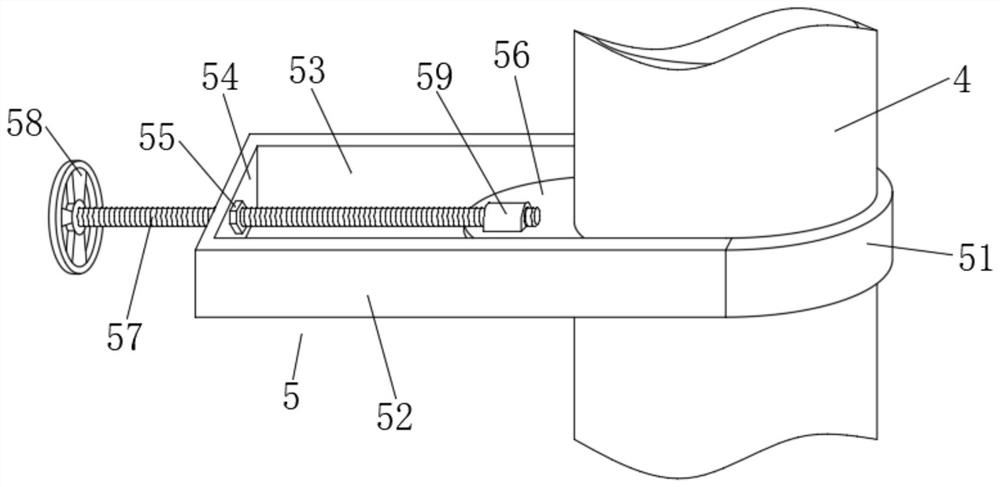

[0023] A device for unloading and bagging the grinding body of a ball mill, comprising a ball mill barrel 1 and a movable chute 2, the movable chute 2 forms an angle of 30 degrees with the horizontal plane, which is convenient for better unloading through the action of gravity; the said The bottom of the ball mill barrel 1 is provided with a mill door outlet 17, through which the mill door outlet 17 is convenient for better unloading operation; the outside of the ball mill barrel 1 and the outside of the mill door outlet 17 are connected with a funnel-shaped structure by screws The unloading connecting pipe 3, the bottom of the unloading connecting pipe 3 is fixedly connected with a guide pipe 4, the middle part of the guide pipe 4 is provided with a manual gate assembly 5, and the guide pipe 4 is far away from the bottom of the unloading connecting pipe 3 One end extends to the inside of the movable chute 2, the bottom of the movable chute 2 is fixedly connected to one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com