Simple organic waste anaerobic fermentation equipment

An organic waste and anaerobic fermentation technology, applied in the field of simple organic waste anaerobic fermentation equipment, can solve the problems of slow discharge and movement of gas and waste liquid, and achieve the effect of improving the circulation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

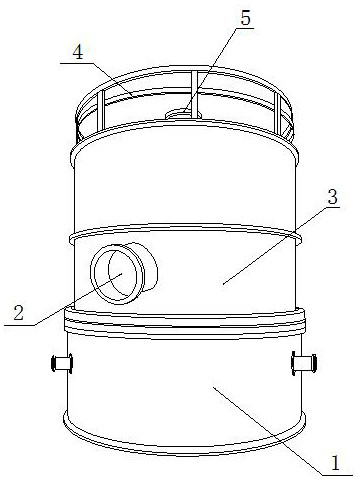

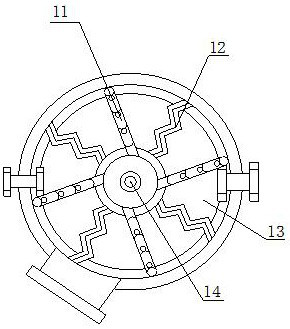

[0030] Append figure 1 Adherent Figure 5 Down:

[0031] Its structure includes driving the base 1, the discharge tube 2, the fermentation case 3, the guardrail 4, the upper end of the drive base 1 is nested in the bottom of the fermentation case 3, the front surface of the fermentation box and the drain tube 2 Internal flange, the top of the drain tube 2 is fitted with the lower end gap of the adder 5, and the lower end of the adder 5 is welded to the top of the fermentation case 3, and the top of the fermentation box 3 is welded at the bottom of the guardrail 4 The drive base 1 includes a stirring pan 11, a blowing strip 12, a carrier plate 13, a drive shaft 14, and a wiping strip 12 gap, the scraping strip 12 surface and loading The surface profile of the substance plate 13, the center of the carrier plate 13 is nested in the drive shaft 14, the center of the drive shaft 14 engages the interior of the agitating disk 11.

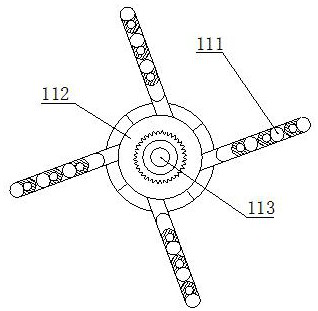

[0032] Wherein, the agitation disk 11 includes a stirred ...

Embodiment 2

[0038] Append Figure 6 Adherent Figure 9 Down:

[0039] Wherein, the scraper strip 12 includes a blade 121, a sleeve plate 122, a card slot 123, and a tapered plate 121, a socket plate 122, a hollow surface and a card slot 123. Nested connections, both sides of the card slot 123 and the outer end gap of the blade 121, the blade 121 is provided with four strips, and the end is embedded with the surface of the sleeve plate 122, wherein the blade 121 has It is beneficial to promote the drainage of waste slag debris on the surface of the carrier plate.

[0040] Wherein, the blade 121 includes a plate body B1, an internal flow tank B2, a front adapter B3, and the inside of the plate body B1 is integrally coupled with the internal flow groove B2, the inner stream tank B2 lower end and the front adhesive shovel B3 The top activity is fitted, and the front adapter B3 is embedded with the surface of the plate body B1, which is distributed in the inner side of the plate body B1, and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com