Forging burr removing device for high-end equipment manufacturing

A technology for equipment and forgings, applied in the field of forging burr removal equipment for high-end equipment manufacturing, can solve the problems of time-consuming, labor-intensive, easy to make people tired, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A kind of forging burr removal equipment for high-end equipment manufacturing, such as Figure 1-3 As shown, it includes a bottom plate 1, a shelf 2, a placement mechanism 3 and a stamping mechanism 4. The left side of the bottom plate 1 is connected to the front and rear sides of the shelf 2, the right side of the bottom plate 1 is provided with a placement mechanism 3, and the shelf 2 is connected to a stamping mechanism. 4.

[0070] Placement mechanism 3 includes main frame 31, first rotating shaft 32, fixed plate 33, placement panel 34, second rotating shaft 35 and Liuling roller 36, base plate 1 right side is provided with main frame 31, main frame 31 top left and right sides are all Rotationally connected with the first rotating shaft 32, the front and rear sides of the main frame 31 are connected with fixed plates 33, the fixed plate 33 is connected with the first rotating shaft 32 in a rotational manner, and the first rotating shaft 32 is connected with Liuling ...

Embodiment 2

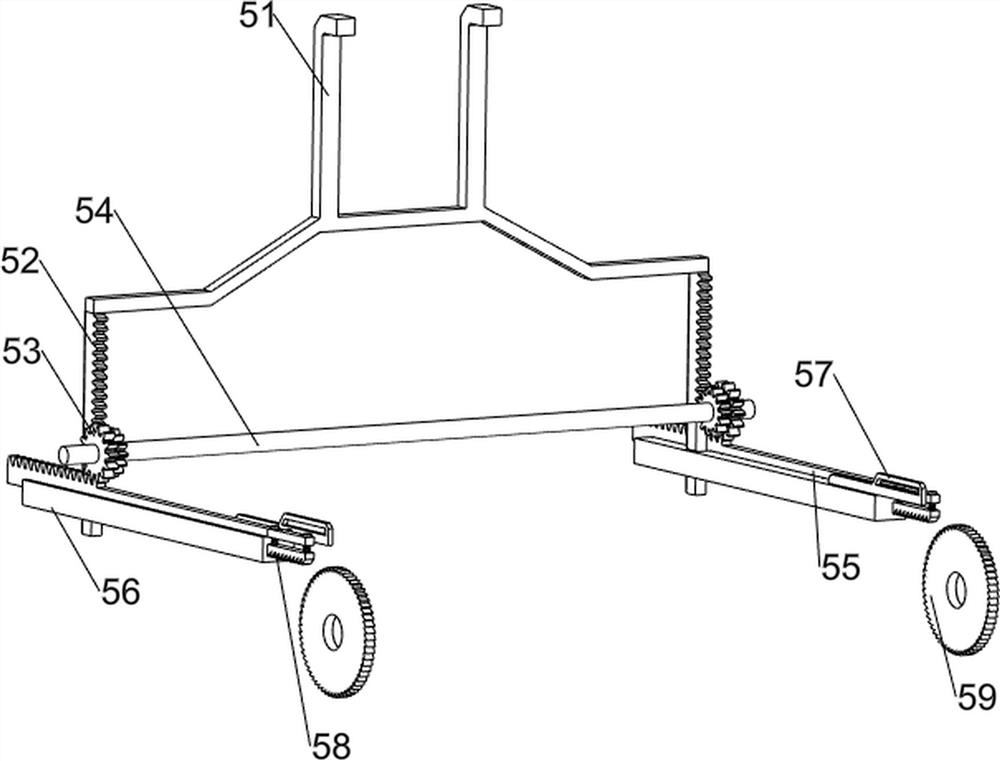

[0074] On the basis of Example 1, such as Figure 4-7 As shown, also includes rotating device 5, and rotating device 5 includes first push rod 51, first rack 52, gear set 53, rotating rod 54, second rack 55, groove frame 56, ladder block 57, ratchet The rack 58 and the ratchet gear 59 are connected with the first push rod 51 between the front and rear sides of the bottom of the pressing plate 43. Rotating rod 54, the front and rear sides of rotating rod 54 are all connected with gear group 53, and gear group 53 is made up of two gears, and two gears are provided with rotating rod 54 front and rear sides respectively, and gear group 53 meshes with first rack 52, The front and rear sides of the top of the shelf 2 are connected with a rack 56, the rack 56 is slidably connected with a second rack 55, the second rack 55 meshes with the gear set 53, and the right side of the second rack 55 is provided with a ladder. The block 57 and the ladder block 57 are provided with ratchet rac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com