Chain processing equipment

A technology for processing equipment and chains, applied in the direction of metal chains, etc., can solve the problem of multiple times of loading and unloading by staff, and achieve the effects of high automation, high work efficiency, high practicability, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

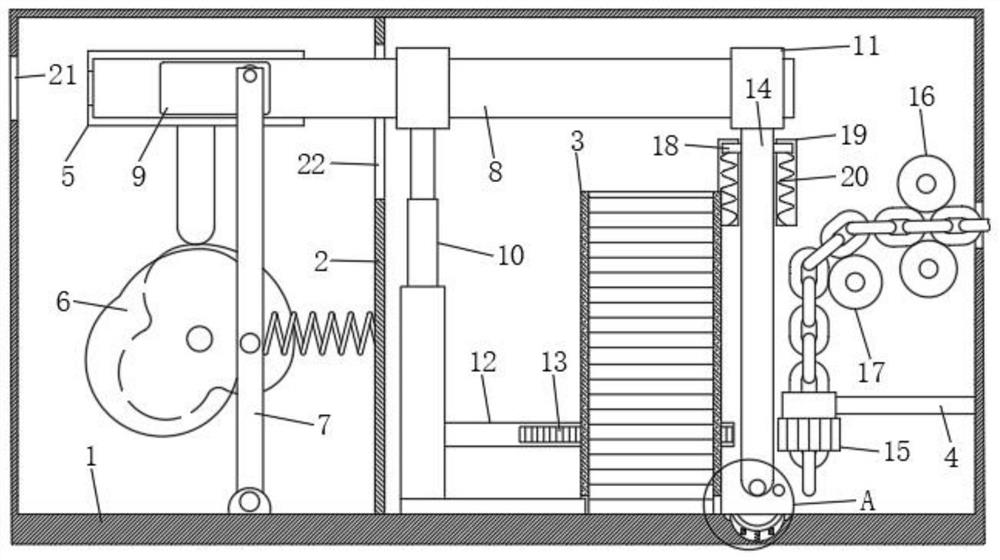

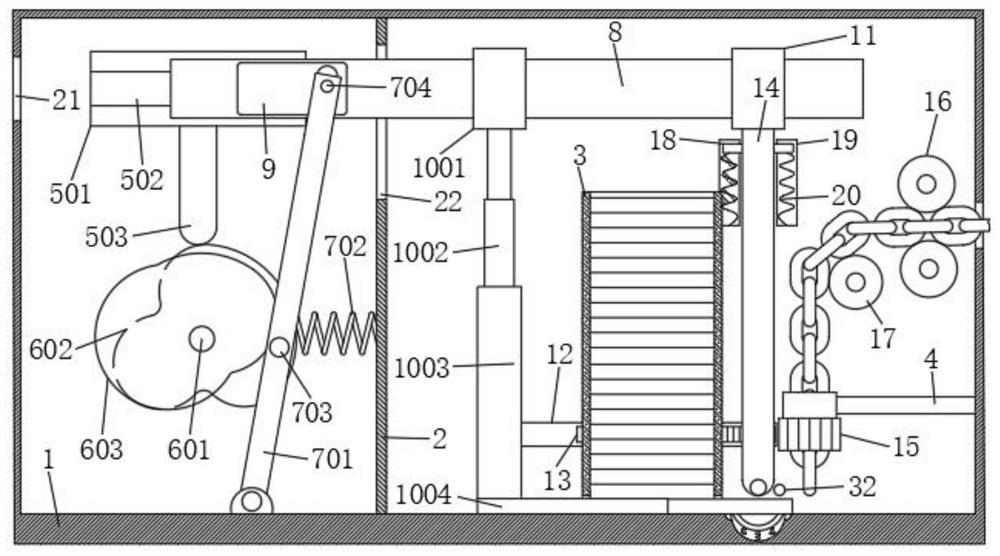

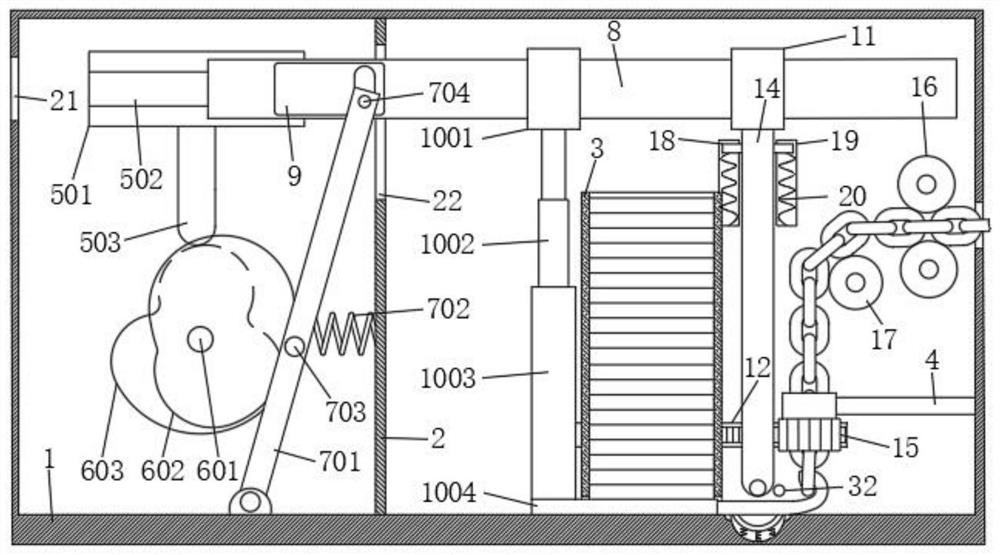

[0043] Such as Figure 1-9 As shown, the embodiment of the present invention provides a chain processing equipment: comprising a box body 1, the interior of the box body 1 is fixedly equipped with a partition plate 2, a discharge box 3, a bracket 4 and a push rod 32, and the bottom of the bracket 4 is rotatably installed with Gear 15, the inside of the box body 1 is equipped with a rotating assembly 6, a left and right adjustment assembly 7, a guide shaft 17 and two traction shafts 16, the inside of the box body 1 is provided with an up and down adjustment assembly 5, and the up and down adjustment assembly 5 is connected with the left and right adjustment assembly. 7 are all attached to the rotating assembly 6, the front of the up and down adjustment assembly 5 is provided with a central shaft 8, the front surface of the central shaft 8 is fixedly installed with a square plate 9, and the outer surface of the central shaft 8 is covered with a pushing assembly 10 and a set block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com