Drill bit used for blind hole and capable of achieving automatic measurement

An automatic measurement and drill technology, applied in metal processing and other directions, can solve problems such as the inability to measure the depth of blind holes, the inability to achieve multi-aperture processing, and the occurrence of defective products, so as to avoid the scrap of circuit boards and reduce the time for replacing drill bits. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

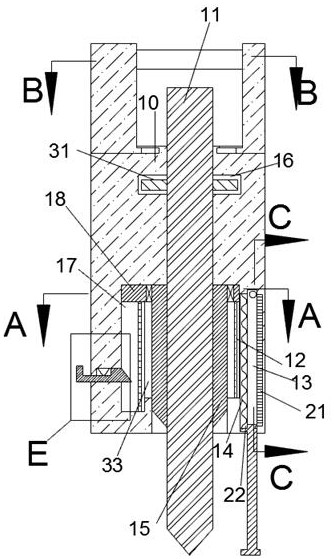

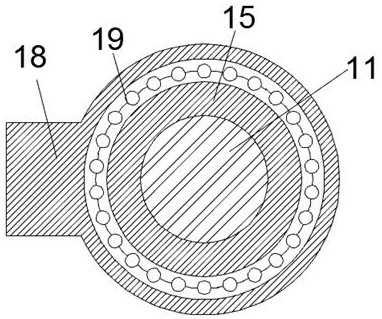

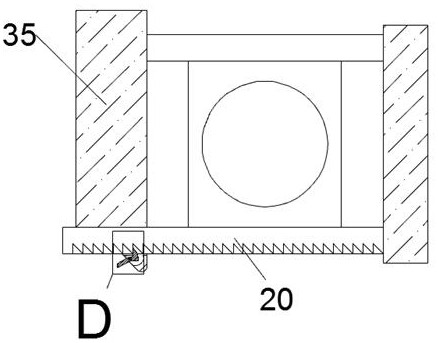

[0021] Combine below Figure 1-7 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0022] combined with Figure 1-7 The described drill bit for blind hole and automatic measurement includes auxiliary equipment 10, which is arranged on the auxiliary equipment 10 to fix the drill bit on the drilling machine, and is arranged on the auxiliary equipment 10 to obtain the blind hole. The measurement component for real-time measurement of the hole depth is set in the auxiliary equipment 10 to replace the drill bit diameter. The replacement component includes an electric telescopic component for telescopic control and a clamping component for fixing the large-diameter drill bit 15 . A limiting component that prevents the large-aperture drill 15 from being reset, the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com