Feed packaging equipment

A feed and equipment technology, applied in the field of feed packaging equipment, can solve the problems of wasting human and material resources, and the pellets cannot be packaged, and achieve the effect of reducing operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

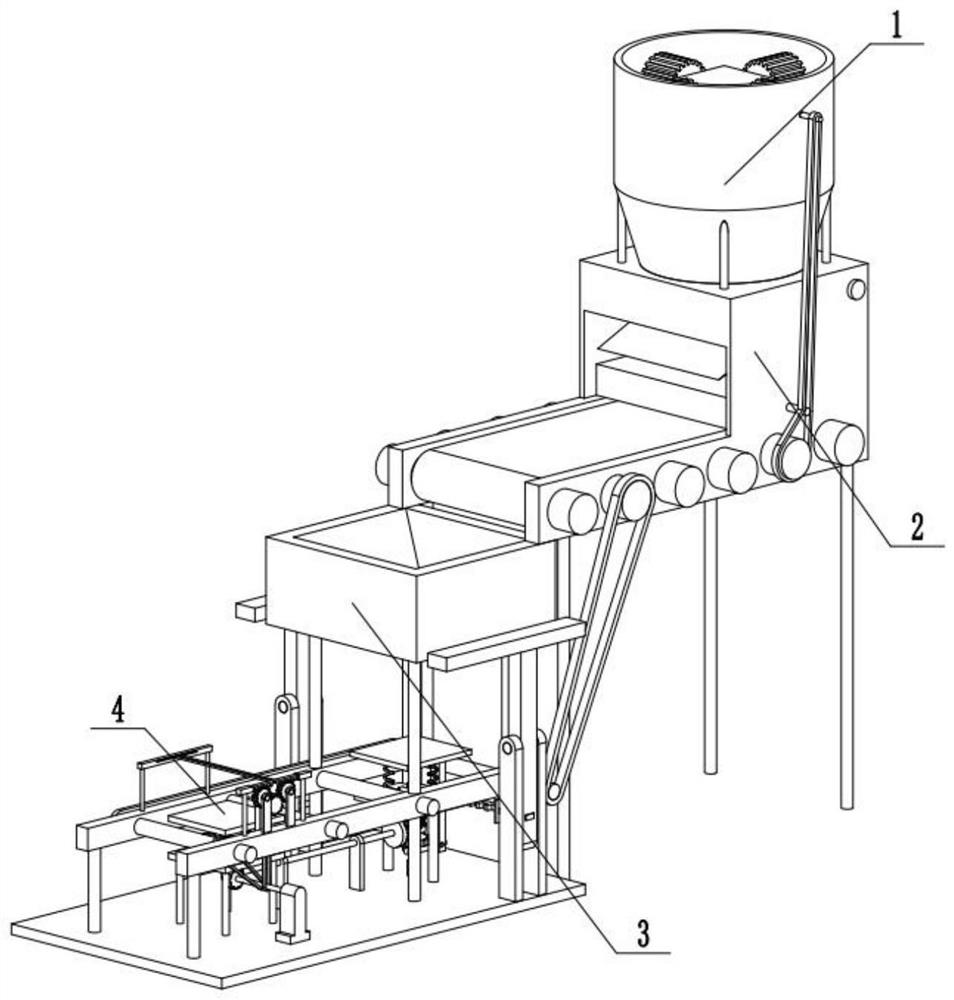

[0031] Combine below Figure 1-14 Describe this embodiment, a feed packaging equipment, including a feed assembly 1, a transmission assembly 2, a packaging assembly 3, and a sealing assembly 4, the feed assembly 1 is connected to the transmission assembly 2, and the transmission assembly 2 is connected to the sealing assembly 4, Packing assembly 3 is connected with sealing assembly 4.

specific Embodiment approach 2

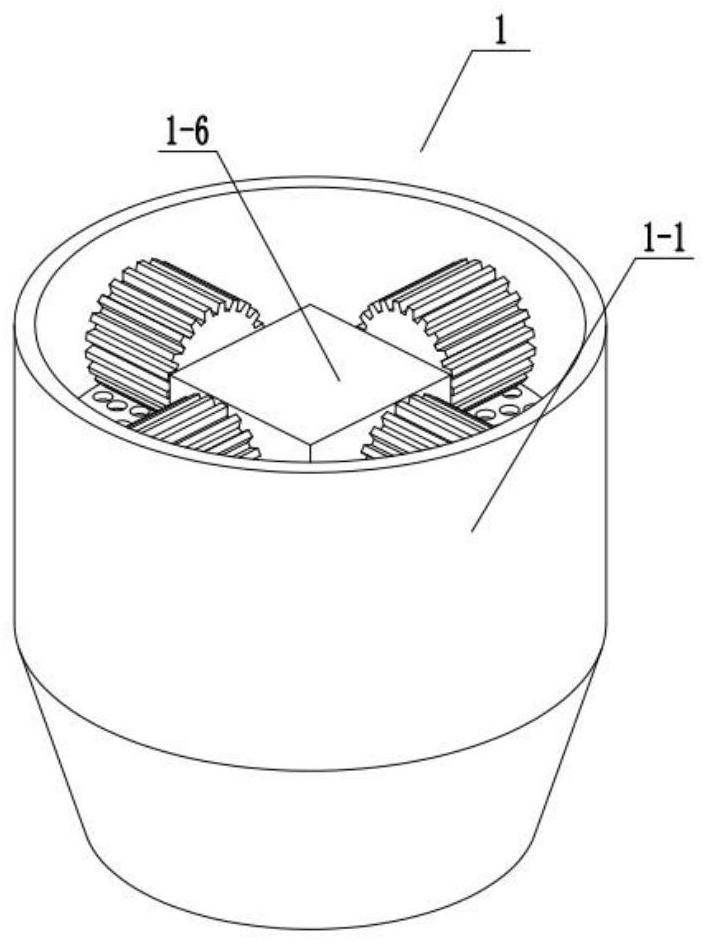

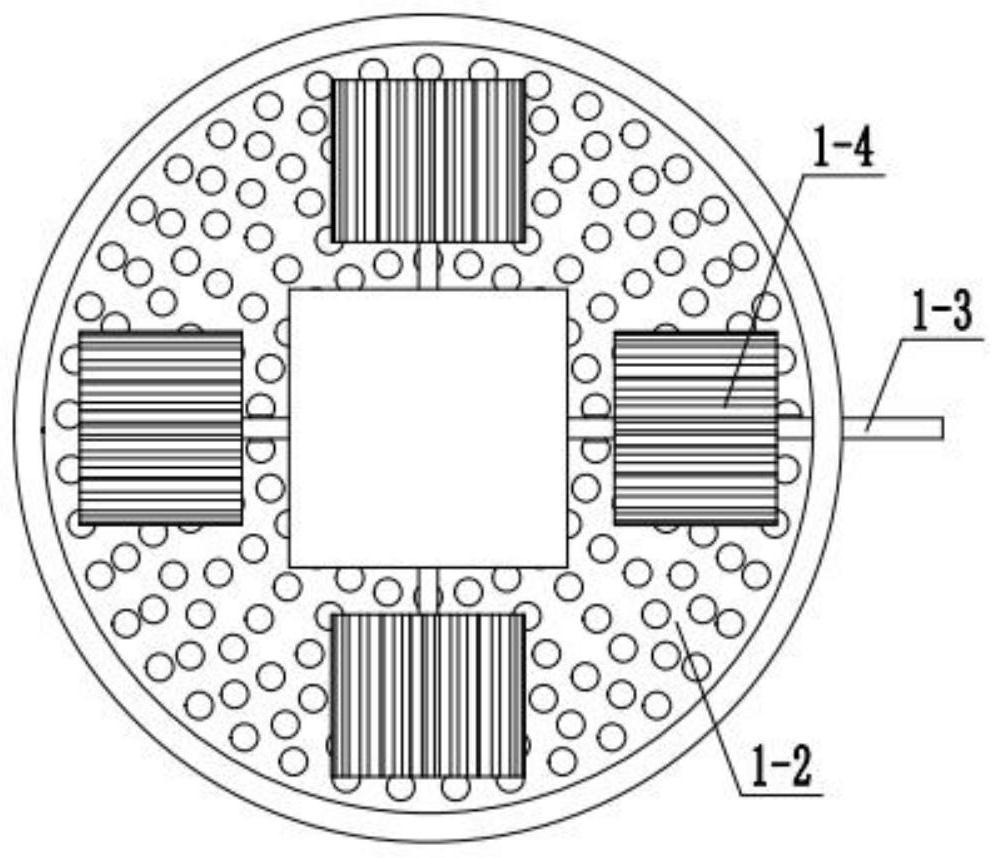

[0033] Combine below Figure 1-14Describe this embodiment, this embodiment will further explain Embodiment 1. The feed assembly 1 includes a feed bucket 1-1, a grinding disc 1-2, a transmission shaft 1-3, a pressure wheel 1-4, and a spur gear 1-5. , chassis 1-6, end face gear 1-7, cutter shaft 1-8, blade 1-9, feed bucket 1-1 is fixedly connected with grinding disc 1-2, feed bucket 1-1 and transmission shaft 1-3 rotate Connection, transmission shaft one 1-3 is fixedly connected with pressure roller 1-4, transmission shaft one 1-3 is fixedly connected with spur gear 1-5, transmission shaft one 1-3 is rotationally connected with chassis 1-6, and spur gear 1- 5 is meshed with the end gear 1-7, the chassis 1-6 is fixedly connected with the grinding disc 1-2, the end gear 1-7 is fixedly connected with the cutter shaft 1-8, and the cutter shaft 1-8 is rotationally connected with the chassis 1-6 , the cutter shaft 1-8 is fixedly connected with the blade 1-9;

[0034] Put the feed in...

specific Embodiment approach 3

[0036] Combine below Figure 1-14 Describe this embodiment. This embodiment will further explain Embodiment 1. The transmission assembly 2 includes a conveyor belt bracket 2-1, a roller 2-2, a conveyor belt 2-3, a transmission belt 2-4, and a transmission shaft 2-2. 5. Cam 2-6, connecting rod 2-7, load-bearing block 2-8, feeding plate 2-9, spring 1 2-10, conveyor belt bracket 2-1 is fixedly connected with feed barrel 1-1, conveyor belt bracket 2-1 Rotately connected with roller one 2-2, roller one 2-2 is connected with conveyor belt 2-3, transmission belt one 2-4 is connected with roller one 2-2, transmission belt one 2-4 is connected with drive shaft two 2- 5 is matingly connected, transmission belt one 2-4 is cooperatively connected with transmission shaft one 1-3, transmission shaft two 2-5 is rotationally connected with conveyor belt support 2-1, transmission shaft two 2-5 is fixedly connected with cam 2-6, and cam 2 -6 is fixedly connected with the connecting rod 2-7, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com