Special self-locking lifting appliance for steel structure

A steel structure and spreader technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve problems such as risk reduction, and achieve the effects of risk reduction, convenient operation, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

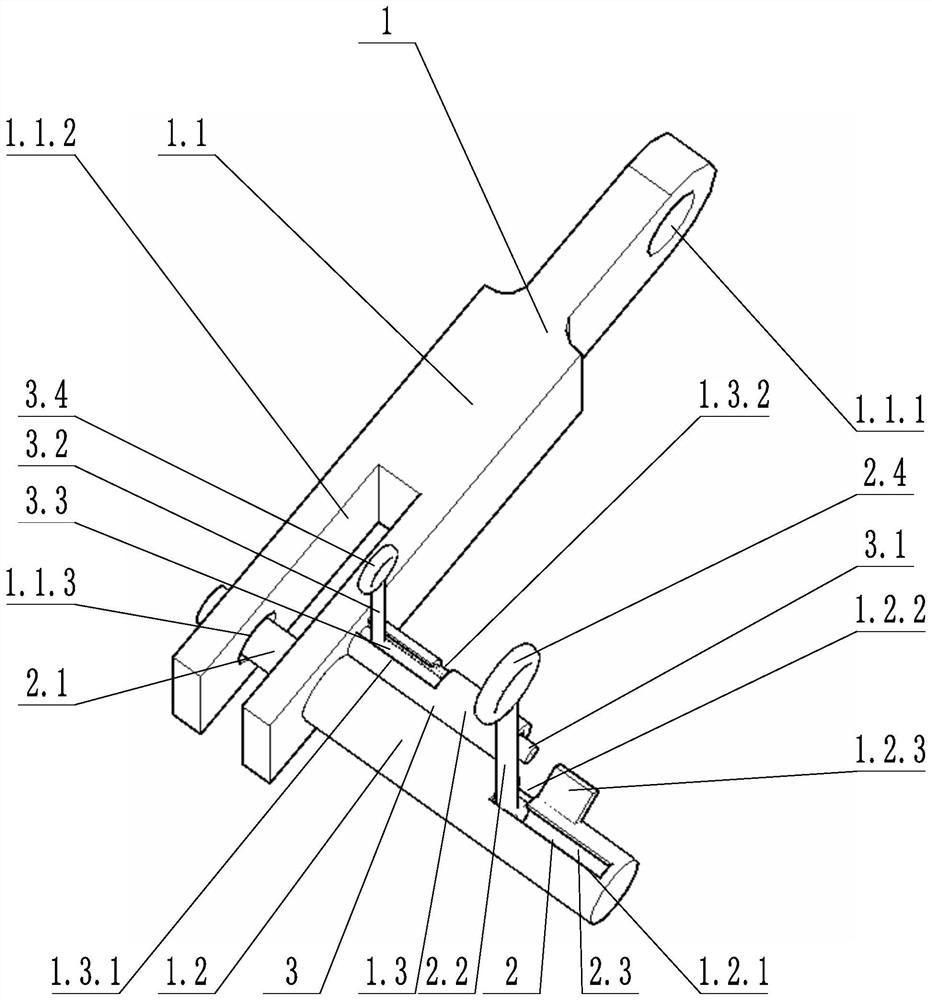

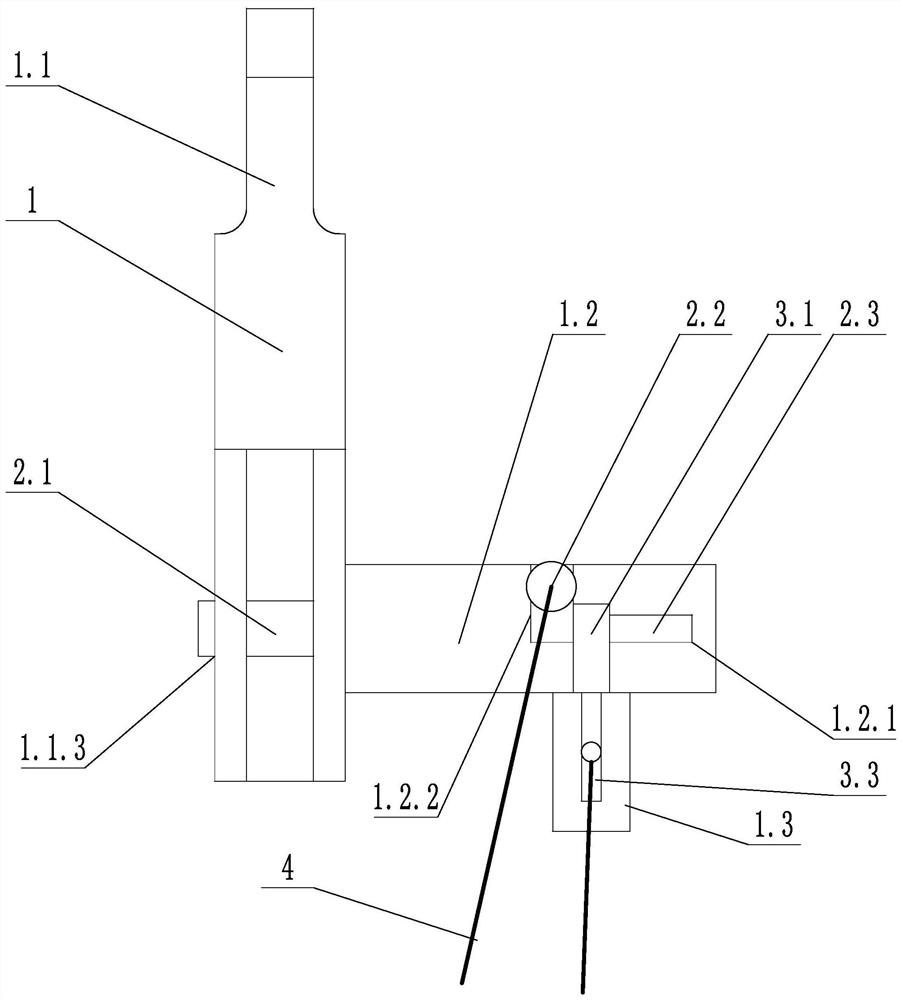

[0031] Such as image 3 As shown, a special self-locking spreader is dedicated to a steel structure, including a spreader body 1, a fixing structure 2, a lock structure 3, and a drawn rope 4, and the spreader body 1 includes a connection block 1.1, a first set of tube 1.2 and the second set. Tube 1.3, the first sleeve 1.2 is perpendicular to the axis of the second sleeve 1.3, and there is a jack 1.1.3 on the connecting block 1.1.3 through the connecting tank 1.1.2, the first set of tube 1.2 The side wall is provided with a first slider 1.2.1 and a first lock groove 1.2.2 in communication.

[0032] The fixing structure 2 includes a fixed latch 2.2, a first lever 2.2 and a first telescopic spring 2.3, and the fixed latch 2.1 is disposed within the first sleeve 1.2 and is slidable with the first sleeve 1.2, and the fixed latch 2.1 can be taken along the first kit 1.2 The axis rotates, one end of the fixed latch 2.3 passes through the jack 1.1.3, and the first telescopic spring 2.3 is ...

Embodiment 2

[0036] Such as figure 1 As shown, a special self-locking spreader is dedicated to a steel structure, including a spreader body 1, a fixing structure 2, a lock structure 3, and a drawn rope 4, and the spreader body 1 includes a connection block 1.1, a first set of tube 1.2 and the second set. Tube 1.3, the connection block 1.1 is provided with a jack 1.1.3, a connecting hole 1.1.1, and a connecting groove 1.1.2, and the jack 1.1.3 pass through the connecting tank 1.1.2, the side wall of the first sleeve 1.2 The first slider 1.2.1 and the first lock slot 1.2.2 are provided with each other; the second lock slot 1.3.1 and the second lock slot 1.3.2 are provided on the side wall of the second sleeve 1.3. .

[0037] The fixing structure 2 includes a fixed latch 2.2, a first lever 2.2 and a first telescopic spring 2.3, and the fixed latch 2.1 is disposed within the first sleeve 1.2 and is slidable with the first sleeve 1.2, and the fixed latch 2.1 can be taken along the first kit 1.2 The...

Embodiment 3

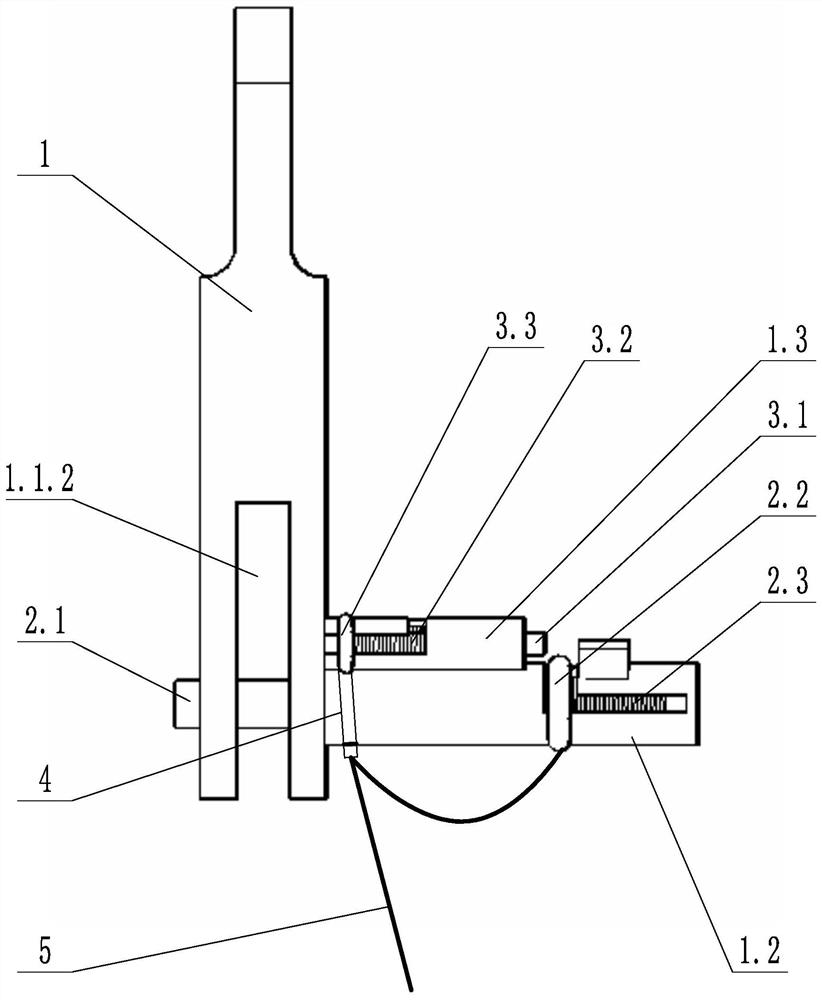

[0041] Such as figure 1 with figure 2 As shown, on the basis of Example 2, the first thus rod 2.2 and the second tilt rod 3.2 are connected to the same roof 4; the second pulley 3.2 is provided with an elastic telescopic member 5, one end and the second end of the elastic scratch piece 5. The tensive rod 3.2 is connected, and one end of the drawing cord 4 is fixed to the elastic telescopic member 5 and connected to the first lever 2.2.

[0042] In the above technical solution, the elastic telescopic member 5 may be a telescopic spring or an elastic elastic rope or other elastic member. One end of the drawstring 4 is bound to the first thus rod 2.2, and the elastic scaling member 5 that is then tied to the second tilt rod 3.2 after the appropriate margin is left. The action of the elastic scratzer 5 is to adjust the length of the rope between the two tie rods and give the second tilt rod 3.2 a certain axial buffer to avoid small do not operate. When you need to unlock, pull the dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com