Coating film detection device and coating equipment

A detection device and position detection technology, which is applied in the field of coating detection devices and coating equipment, to achieve stable performance, facilitate control of uniformity, and improve production efficiency

Pending Publication Date: 2021-07-13

BOE TECH GRP CO LTD +1

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Embodiments of the present disclosure provide a coating detection device and coating equipment to solve or alleviate one or more technical problems in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0033] In the following, only some exemplary embodiments are briefly described. As those skilled in the art would realize, the described embodiments may be modified in various different ways, all without departing from the spirit or scope of the present disclosure. Accordingly, the drawings and descriptions are to be regarded as illustrative in nature and not restrictive.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

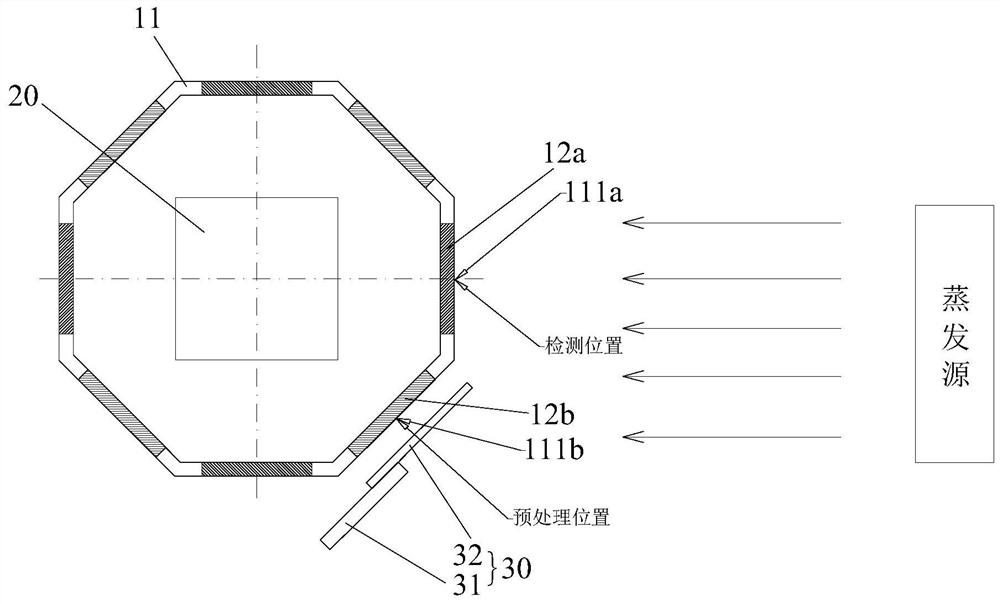

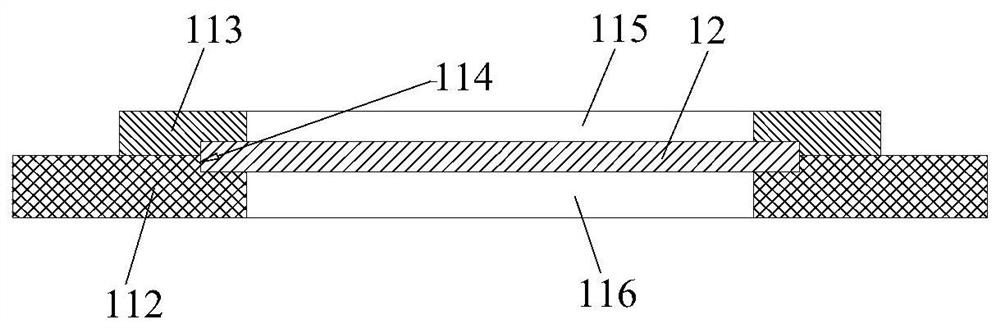

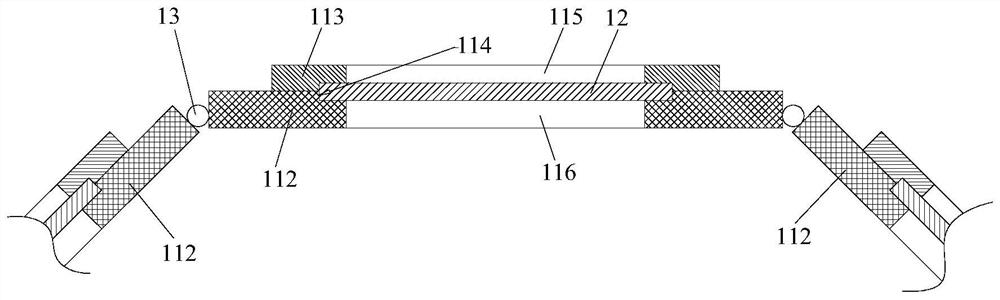

The embodiment of the invention provides a coating film detection device and coating equipment. The coating film detection device comprises a mounting rack, a detection position, a pretreatment position and a first driving mechanism, wherein the mounting rack is at least used for arranging a first detection sheet located at the detection position and a second detection sheet located at the pretreatment position, the detection position is configured to enable the first detection sheet located at the detection position to receive film layer material deposition, the pretreatment position is configured to enable the second detection sheet located at the pretreatment position to receive pretreatment so as to form a preset film layer on the surface of the second detection sheet, and the first driving mechanism is connected with the mounting rack and is used for driving the mounting rack to move so as to convey the pretreated second detection sheet from the pretreatment position to the detection position. According to the technical scheme, the early-stage unstable state of the second detection sheet can be consumed; and when the second detection sheet is adopted for detecting the coating rate, the performance of the second detection sheet is stable, irregular fluctuation of the temperature rate cannot occur, control over the actual film thickness is facilitated, and the production efficiency is improved.

Description

technical field [0001] The present disclosure relates to the field of coating technology, in particular to a coating detection device and coating equipment. Background technique [0002] Coating processes such as vacuum evaporation are widely used in the production process of organic light-emitting diode (Organic Light-Emitting Diode, OLED) display devices and other products. The thickness of some film layers in these products is very low, usually between a few nanometers and hundreds of nanometers. If the thickness is abnormal, it may lead to abnormal performance of the product. Therefore, it is necessary to monitor the thickness of the film layer to monitor the coating process. Control to realize the control of the film thickness. [0003] Existing film thickness detection is usually realized by QCM (Quartz Crystal Microbalance, quartz crystal microbalance). During the coating process, the material of the film layer will be deposited on the QCM crystal oscillator, causin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C14/54C23C14/24

CPCC23C14/546C23C14/24

Inventor 徐天宇贾克飞黄秦霏易平安肖昂刘洋刘金彪李哲

Owner BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com