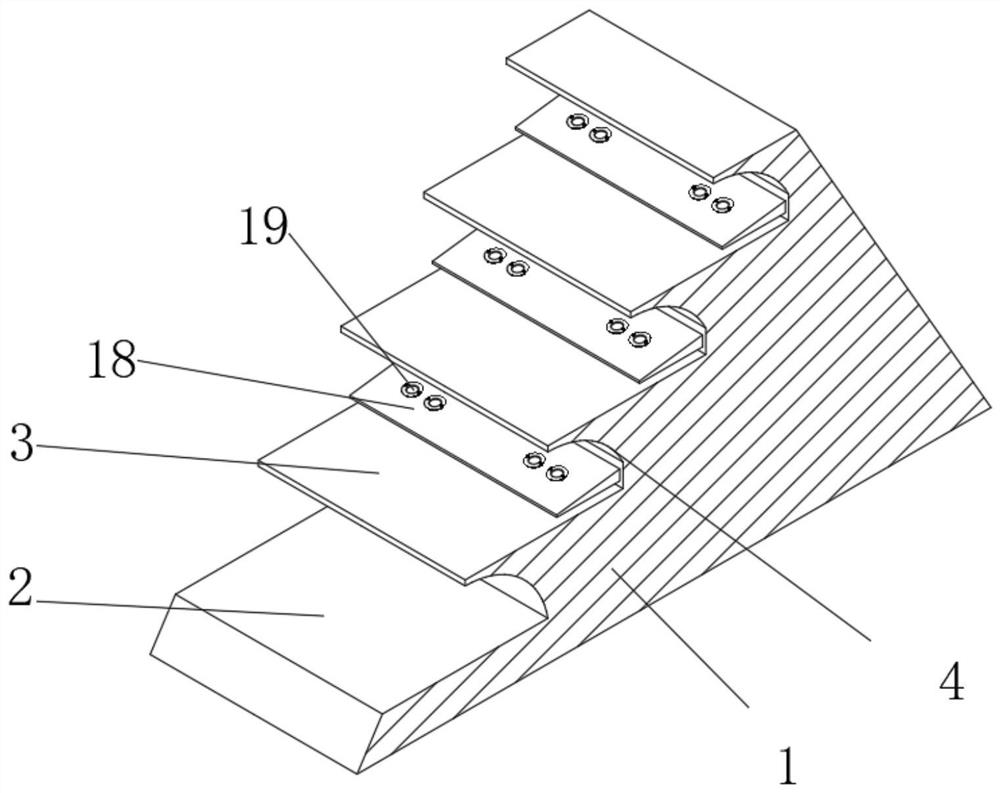

Combined energy dissipation wall for hydraulic engineering

A water conservancy engineering and combined technology, applied in water conservancy engineering, sea area engineering, coastline protection, etc., can solve the problems of large interaction stress, long stilling pool, high cost, etc., achieve automatic cleaning, improve energy dissipation efficiency, improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

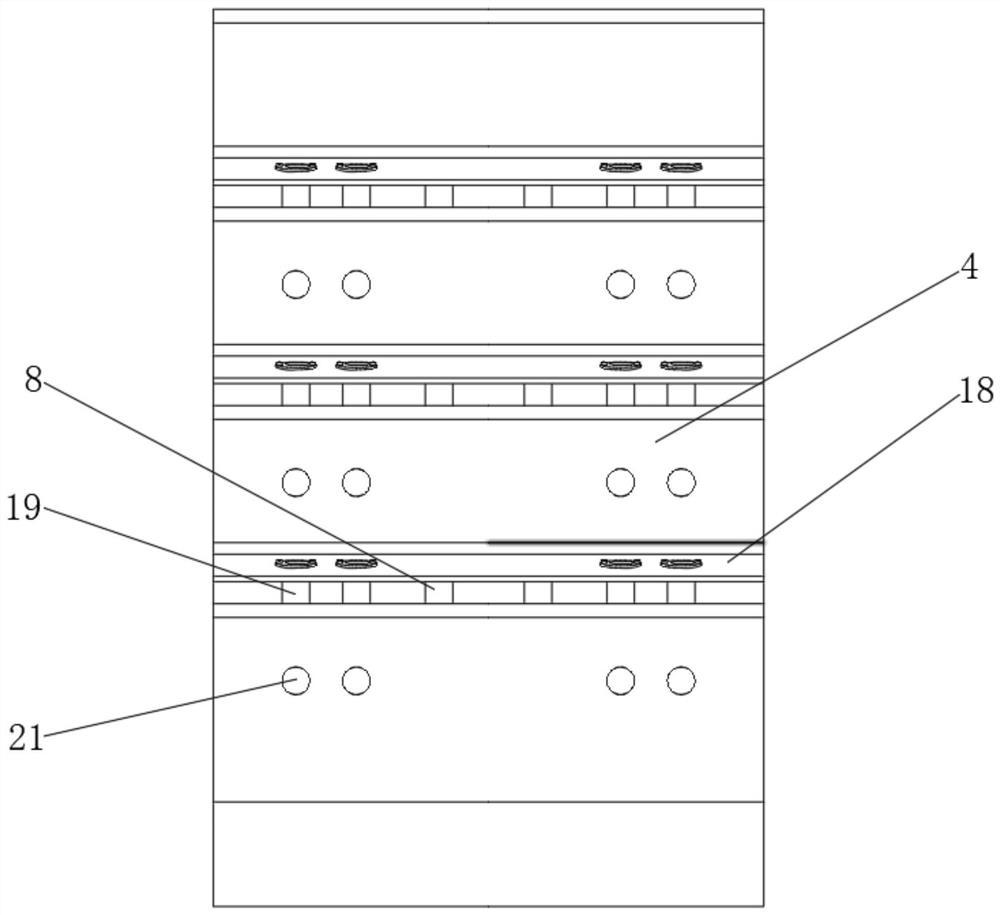

Method used

Image

Examples

Embodiment 2

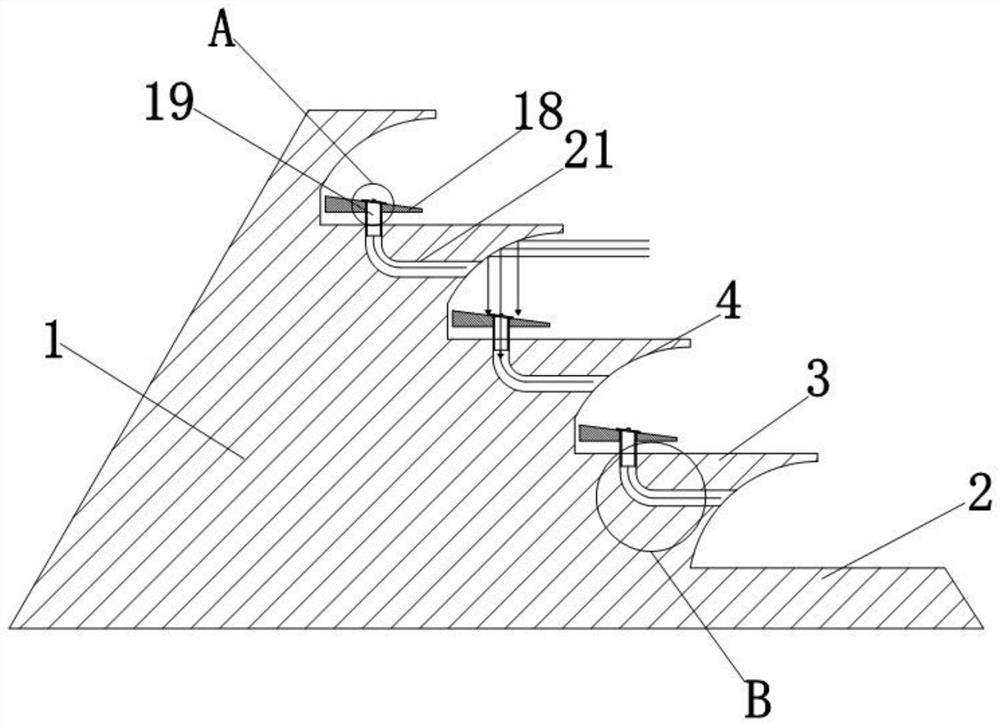

[0035] Because often there are sundries such as branches and plastic garbage floating on the water surface, these sundries often enter in the diversion groove 21 through the moving pipe 19 with the water flow, causing the diversion groove 21 to be blocked, so that the water flow cannot pass through the diversion groove 21. It flows out and flushes the water outside the diversion groove 21; therefore, the blocked sundries will weaken the effectiveness of the device on the water flow, so the device has been further improved.

[0036] Such as Figure 9 As shown, the bottom end of the moving tube 19 is movably socketed in the diversion groove 21. When the water impacts on the buffer plate 18, the buffer plate 18 will go down after being pressured, and at the same time, it will drive the moving tube 19 above it to move downward. At this time, the damping spring 10 will be compressed; when the pressure of the water on the buffer plate 18 disappears, the damping spring 10 resumes its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com