Fireproof steel structure environment-friendly building

A steel structure, environmental protection technology, applied in the direction of fire prevention, construction, building components, etc., can solve the problems of heavy rain noise, large disadvantages, and lack of fire extinguishing function, and achieve the effect of reducing noise, increasing firmness, and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

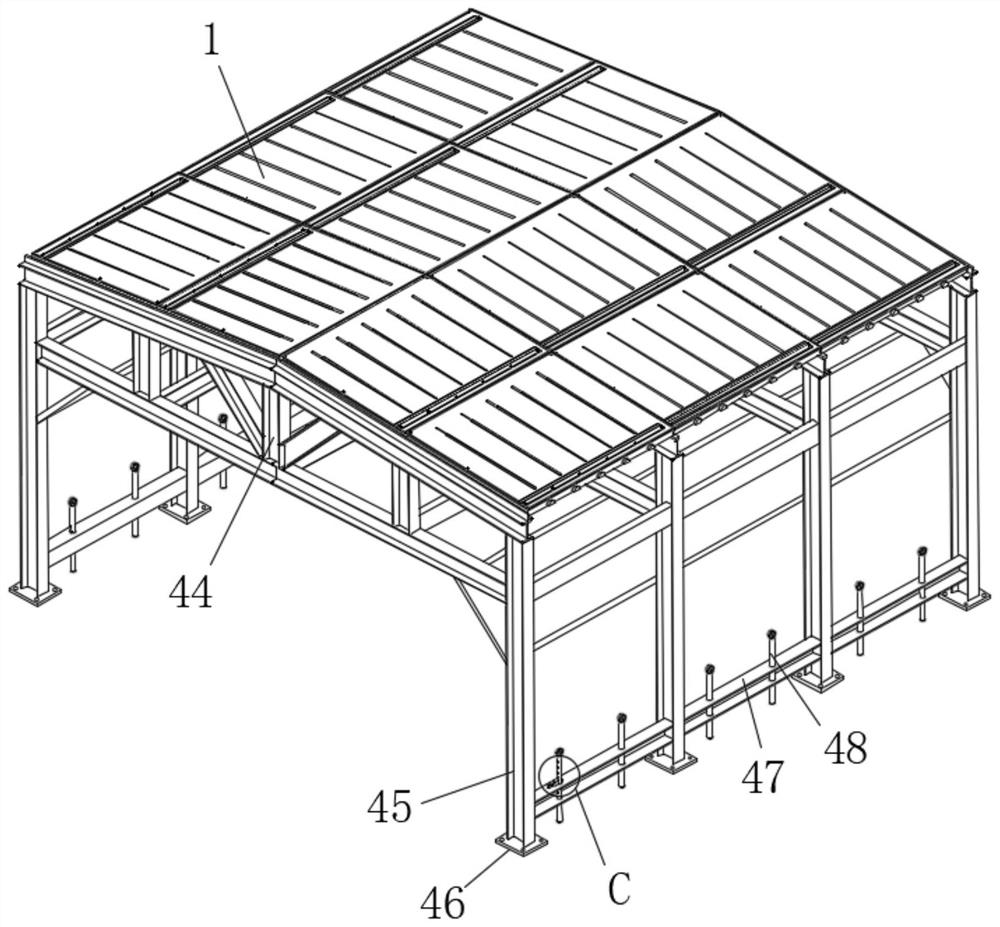

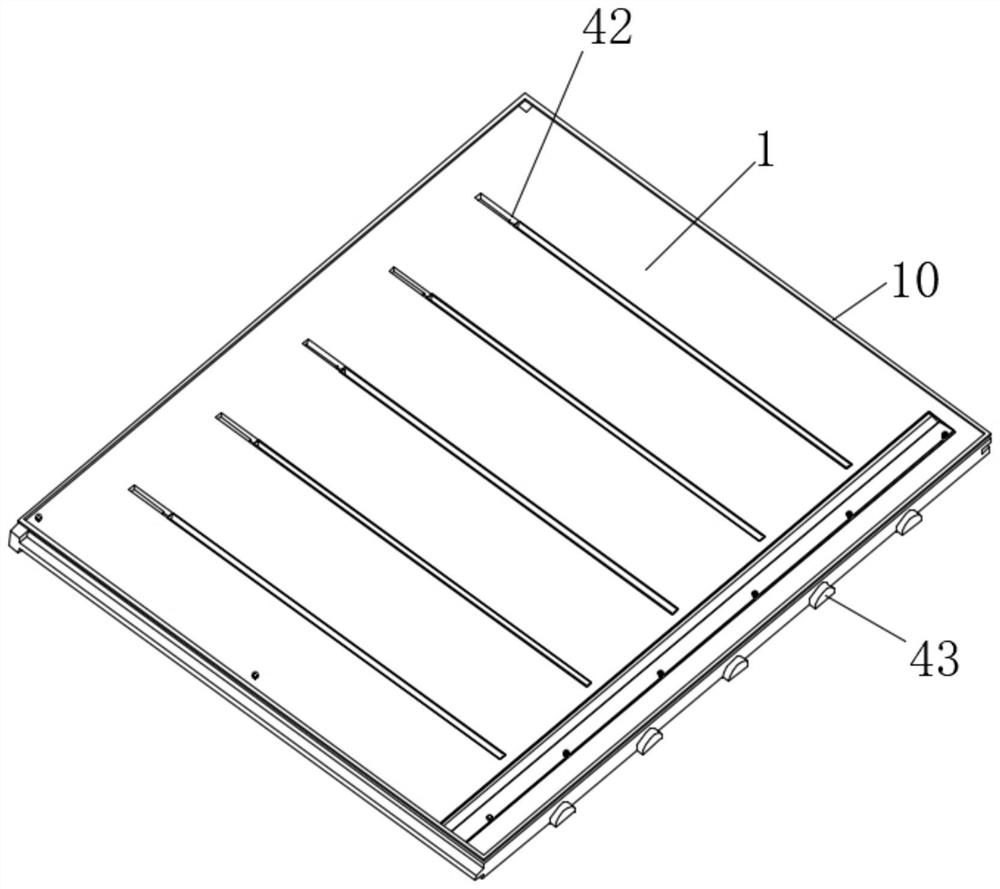

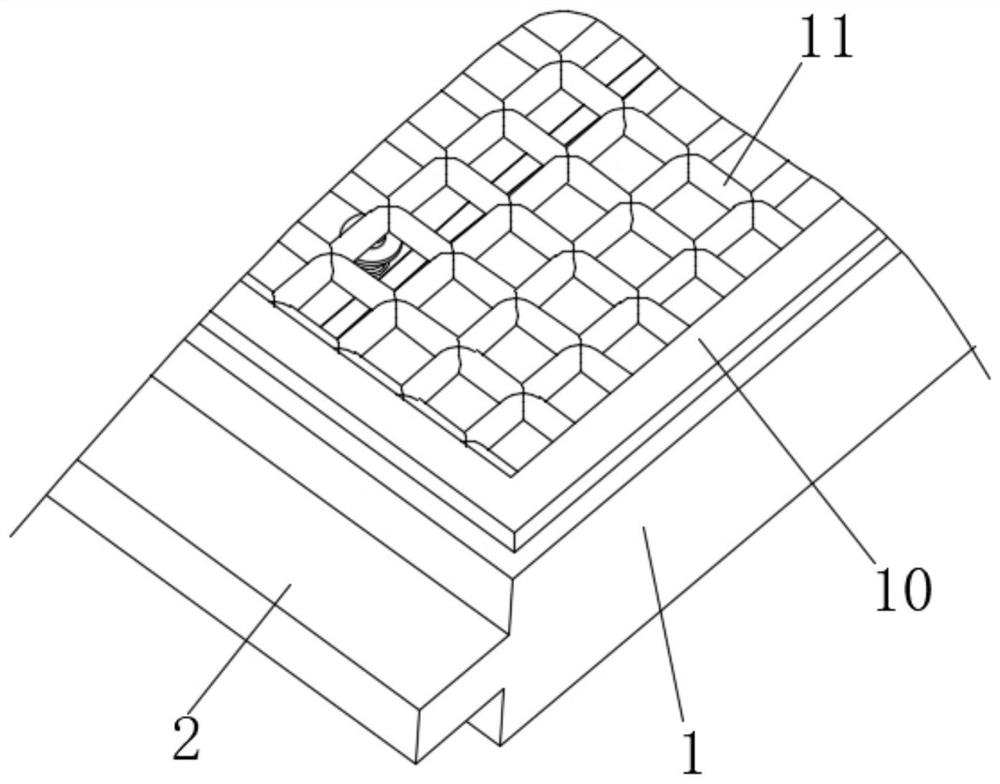

[0036] Such as Figure 1-Figure 13 A fireproof steel structure environment-friendly building is shown, including a roof 1, the roof 1 is arranged in several pieces and the edges are spliced together, and the several roofs 1 form a plate shape with both sides extending obliquely downward. A support structure is installed on the end faces, and a water storage cylinder 6 is embedded in the lower side near the top plate 1. The upper end port of the water storage cylinder 6 is fixedly installed with an upper corner cutting plate 7 and a lower corner cutting plate 8, and the upper corner cutting plate 7 and The adjacent edges of the lower corner-cutting plate 8 jointly form an inclined channel leading into the inner side of the water storage cylinder 6, and several groups of eight-character partitions 9 are extended from the upper end surface of the upper corner-cutting plate 7, and the two oppositely called eight-character partitions 9 are called a Set in groups, the lower end su...

Embodiment 2

[0038] A fire-resistant steel structure environment-friendly building, comprising a roof 1, which is arranged in several pieces and whose edges are spliced together, the several roofs 1 jointly form a plate shape with both sides extending obliquely downward, and the lower end surfaces of the several roofs 1 are installed together There is a support structure, a water storage cylinder 6 is embedded and installed on the lower side near the top plate 1, and the upper end port of the water storage cylinder 6 is fixedly installed with an upper corner cutting board 7 and a lower corner cutting board 8, and the upper corner cutting board 7 and the lower corner cutting board The adjacent edges of 8 form an inclined passage leading into the inner side of the water storage cylinder 6 together, and several groups of eight-character spacers 9 are extended from the upper end surface of the upper chamfer plate 7, and the eight-character spacers 9 are set in two relative groups. The lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com