Heat exchange assembly capable of achieving switching of working conditions and heat exchanger

A technology of heat exchange components and working conditions, applied in indirect heat exchangers, tubular elements, heat exchange equipment, etc., can solve the problem of uncontrolled heat exchange efficiency adjustment, inability to adjust the opening degree heat exchange efficiency, and difficult to meet heat exchange Fast switching of the device to achieve the effect of prolonging the service life and overcoming the easy blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

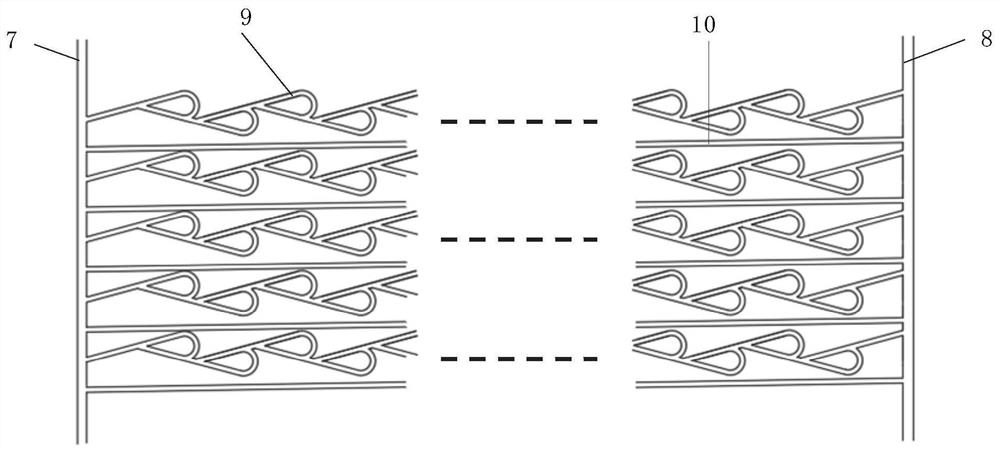

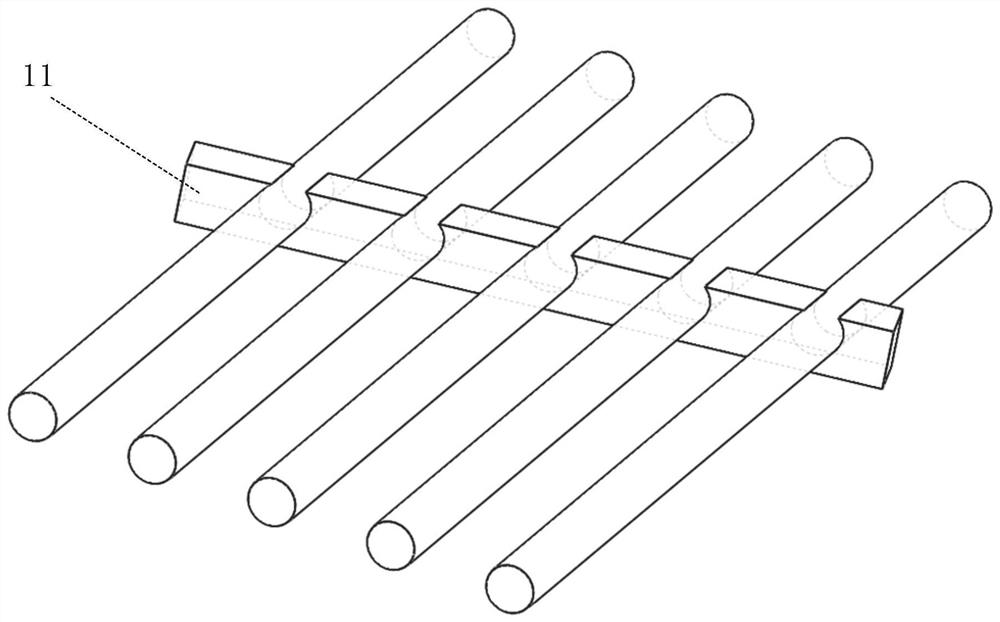

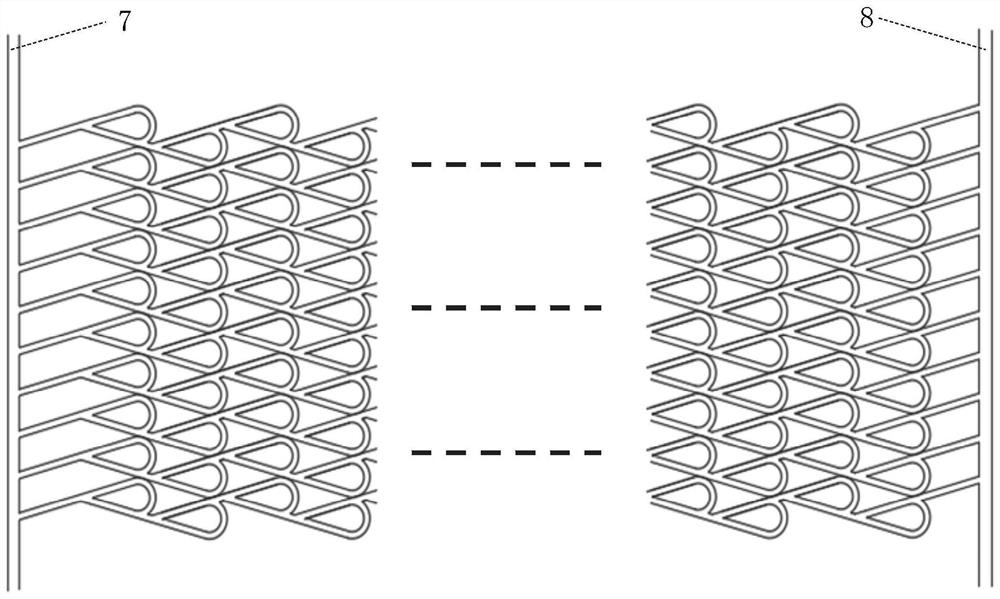

[0031] In a typical implementation of the present disclosure, such as Figure 1-Figure 5 As shown, a heat exchange component with switchable working conditions is proposed.

[0032] Including trunk tube and capillary group, the two trunk tubes form a pair, the two trunk tubes are connected through the capillary group, one trunk tube is used as the liquid inlet tube 7 to input the medium into the capillary group, and the other dry tube The road pipe is used as the drain pipe 8 to recover the medium output by the capillary group, and the capillary group performs heat exchange with the external environment through the internal medium.

[0033] The flow direction of the medium in the two main pipes can be changed. The two main pipes are respectively connected to the two ports of the reversing valve, and the other two ports of the reversing valve are connected to the external water supply pipe and the return pipe; The position can make the water supply pipe communicate with differ...

Embodiment 2

[0061] In another typical implementation of the present disclosure, such as Figure 1-Figure 5 As shown, a heat exchanger is proposed, which utilizes the heat exchange assembly with switchable working conditions as described in Embodiment 1.

[0062] The heat exchange components in the heat exchanger adopt the heat exchange components that can switch working conditions as in Example 1.

[0063] It can be understood that in the same heat exchanger, multiple sets of heat exchange components that can switch working conditions can be arranged in parallel, and all heat exchange components can be controlled by a four-way reversing valve to realize the overall heat exchange of the heat exchanger. Efficiency adjustments;

[0064] It is also possible to configure a four-way reversing valve for each group of heat exchange components. By controlling the reversing valves one by one, more precise control of the overall heat exchanger efficiency can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com