Method for measuring pH value of aqueous solution

An aqueous solution and solution technology, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions. Accurate, improve accuracy and linear relationship, effective screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

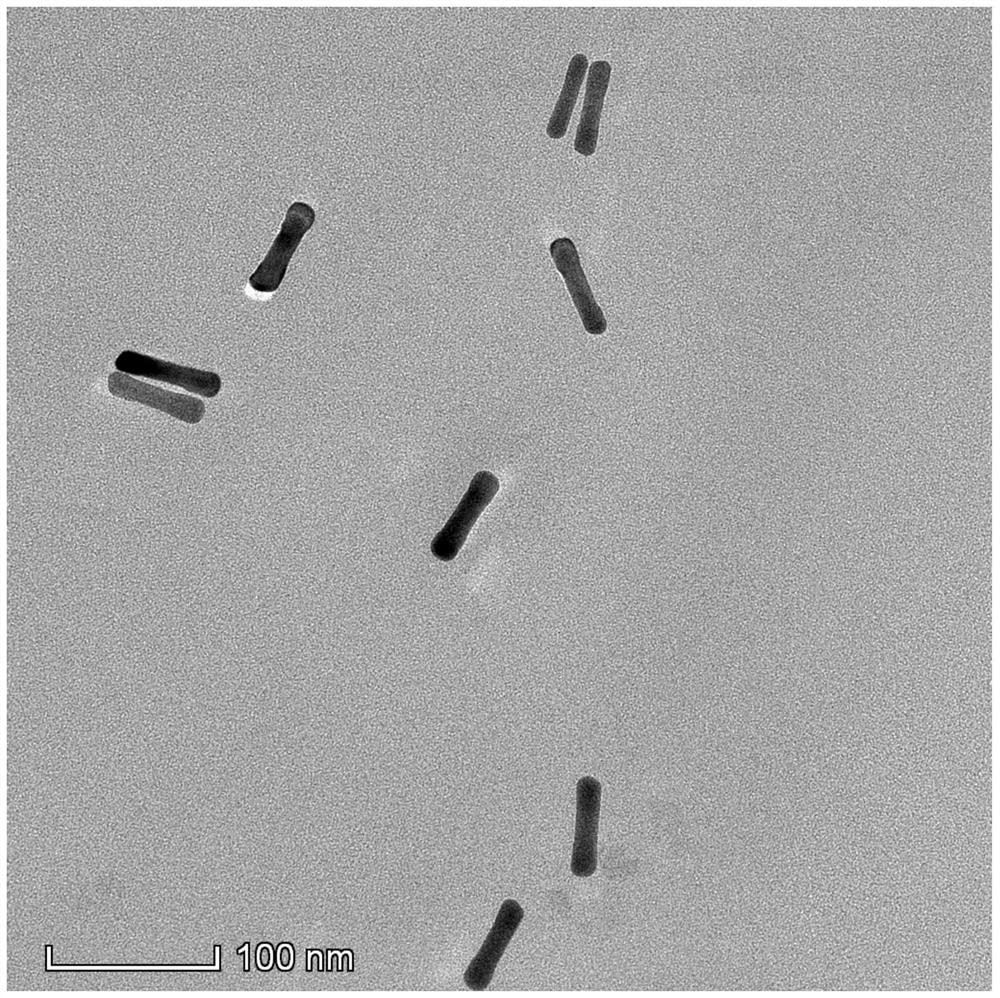

[0037] 1.1 Preparation of gold nanorods

[0038] The AuNRs used in this description were prepared by seed synthesis.

[0039] The seed solution was prepared by mixing 25 μL HAuCl in a 25 mL round bottom flask 4 (50mM) and 5mL CTAB (0.1M). After stirring slowly for 5 min, add freshly prepared 300 μL NaBH 4 solution on ice (0.01 M), then vigorously stirred for 30 sec. Finally, place it in a water bath at 30° C. and incubate for 1 hour to obtain a seed solution.

[0040] Growth solution was prepared as follows: 200 µL HCl (1M), 100 µL HAuCl 4 (50mM) and 10mL CTAB (0.1M) were added into a 50mL glass round bottom flask and stirred gently. Finally, add 120 μL AgNO 3 (10mM) and 100μL ascorbic acid (100mM) to prepare the seed growth solution.

[0041] When preparing AuNRs, inject 24 μL of seed solution into the above seed growth solution and stir vigorously for 30 s, and then incubate in a water bath at 30 °C for 24 hours to wait for the growth to complete. 10 mL of AuNRs was ...

Embodiment 2

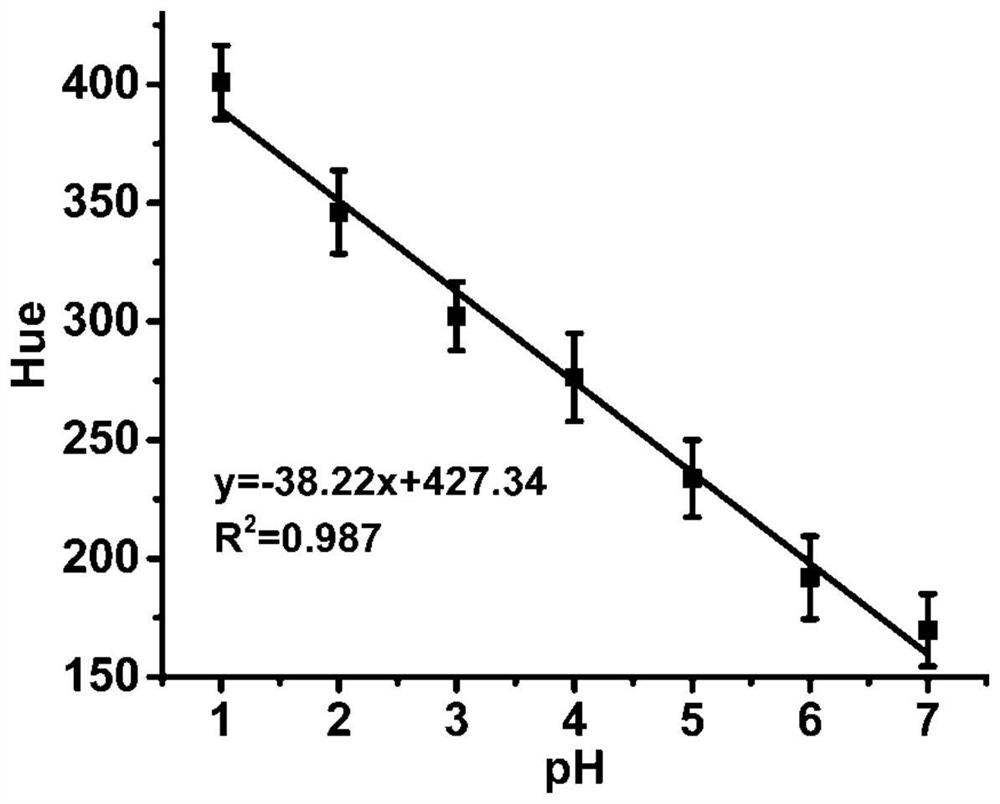

[0045] In this example, the AuNRs synthesized in Example 1 are used to detect the pH value. The AuNRs solution was freshly prepared, the solutions to be tested were standard solutions with pH values of 1.0, 2.0, 3.0, 4.0, 5.0, 6.0, and 7.0, and the etching solution consisted of 3.3mM KI and 6.6MH 2 o 2 composition.

[0046]100 μL of AuNRs solution and 100 μL of etching solution were added to 800 μL of solutions with different pH values, shaken vigorously and then transferred to a cuvette, the etching temperature was 20 °C, and the etching time was 1500 s. , the United States) to monitor, continuously collect RGB signals, and convert the RGB values into the hue value H according to the following formula

[0047]

[0048] R, G and B in formula (1) are the component values of red, green and blue respectively, Max channel and min channel are the maximum and minimum intensities in the red, green, and blue channels.

[0049] Using the newly prepared AuNRs as a colori...

Embodiment 3

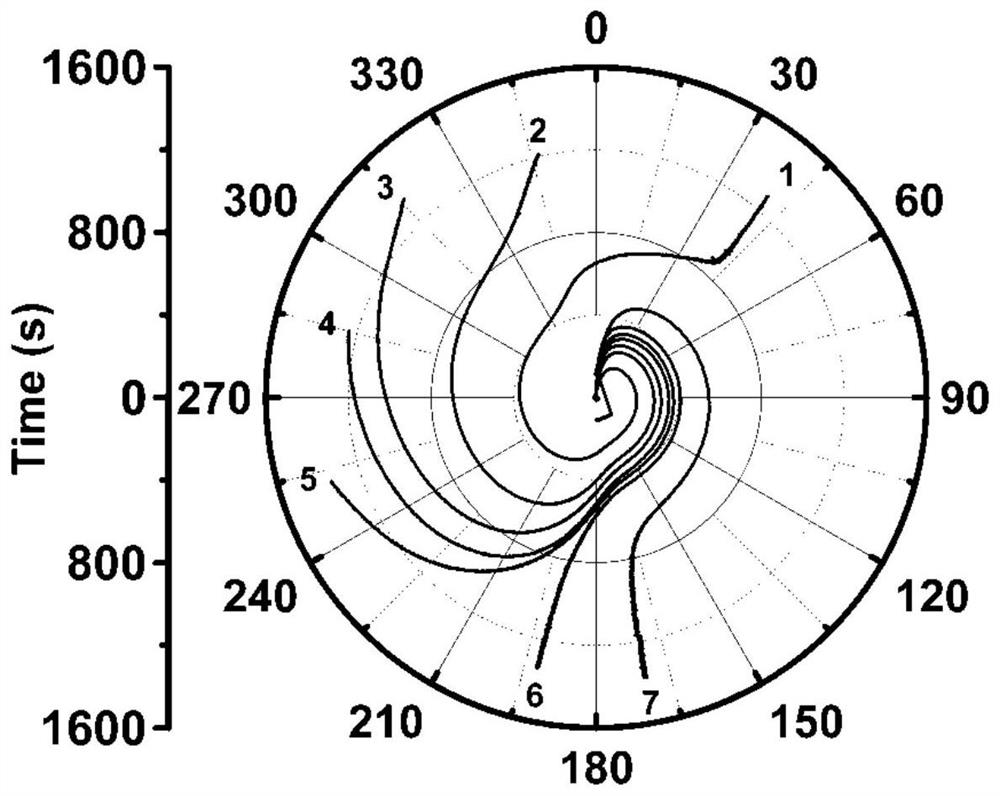

[0054] In this embodiment, the AuNRs after being placed (aged) at room temperature for a long time are used as colorimetric probes for pH measurement.

[0055] After the AuNRs synthesized in Example 1 were left at room temperature for 25 days, they were used as a colorimetric probe, and the pH value of the aqueous solution was measured using the same conditions as in Example 2. It was found that the AuNRs placed for 25 days showed different response patterns ( Figure 4 ), the response rotates counterclockwise at the beginning of the reaction, and then starts to rotate clockwise after 400s. This phenomenon was consistent at every pH value tested. Overall, the resolution between the change curves is poor.

[0056] The maximum tone value is plotted against the pH value, and it can be found that the linear relationship is poor in the range of pH=1-7 ( Figure 5 ), the calibration curve has a lower linear correlation coefficient (R 2 =0.927, less than 0.95), the linear equatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com