Soil crushing type peanut harvester

A technique for peanut harvesters and soil crushing, which is applied to excavating harvesters, harvesters, agricultural machinery and implements, etc. It can solve the problems of peanut fruit leakage and peanut harvesters without the function of mowing grass, so as to avoid fruit leakage and optimize The effect of using performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

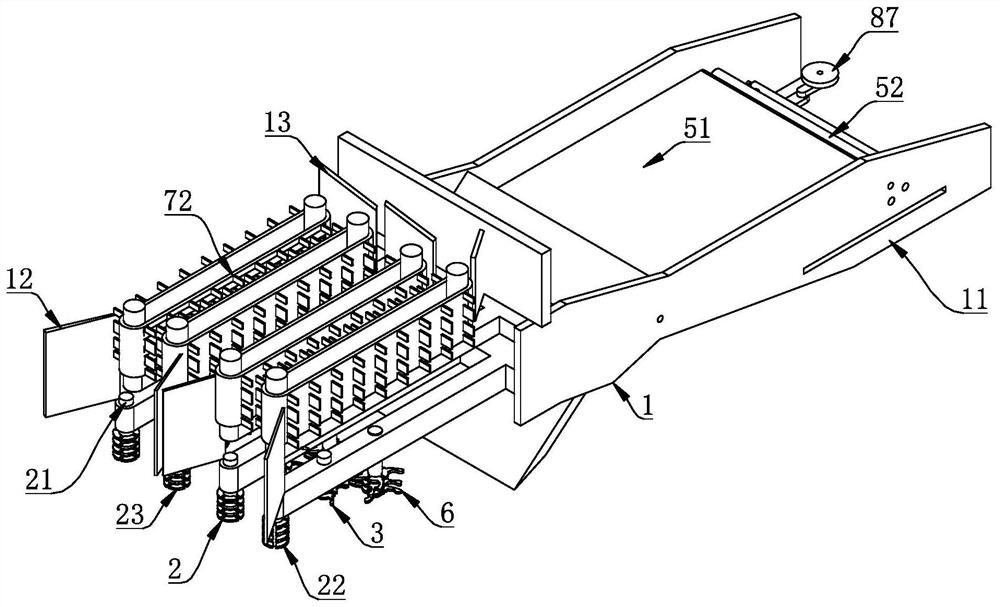

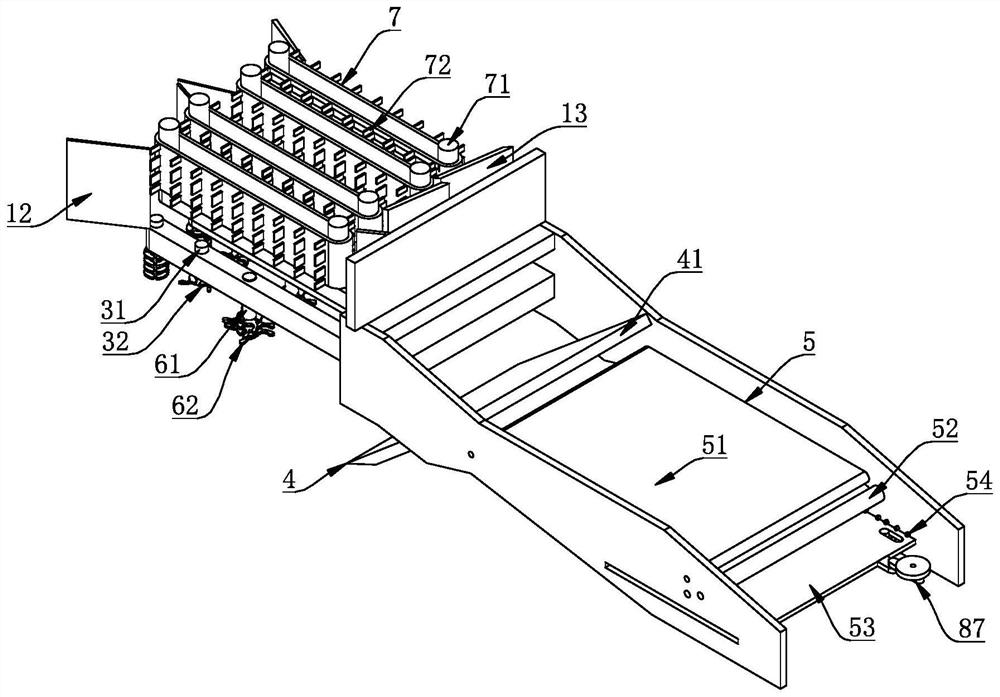

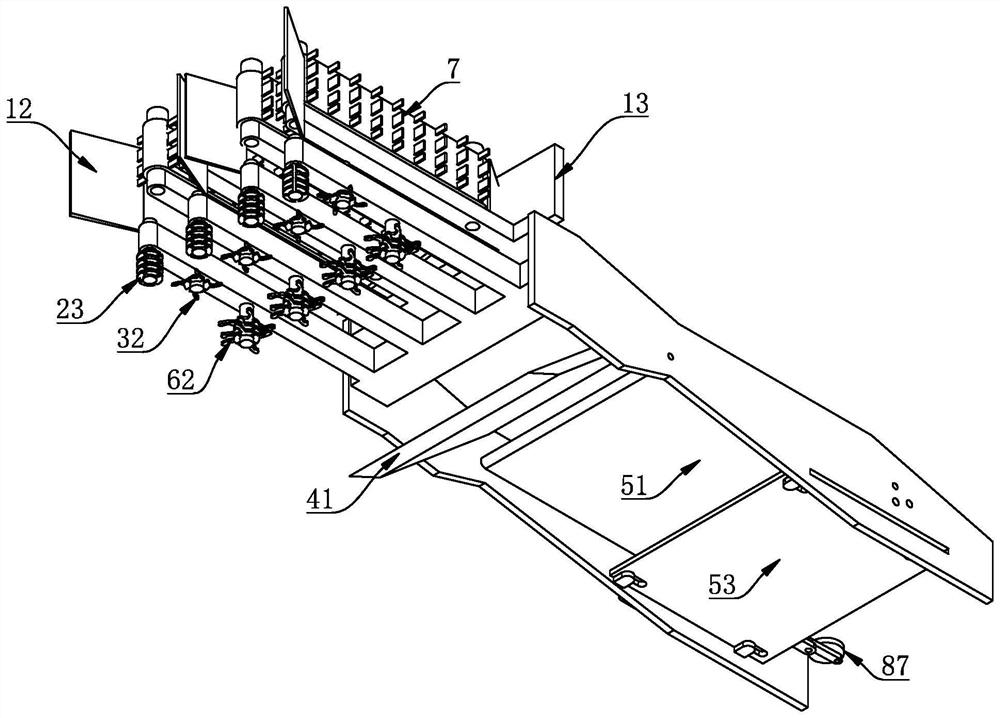

[0042] refer to Figure 1 to Figure 6 , a soil crushing type peanut harvester, comprising a frame 1, the frame 1 is provided with a mowing assembly 2, a seedling cutting assembly 3, a soil shovel assembly 4 and a separation assembly 5 separating the soil from the peanuts, the The seedling assembly 3 is located between the mowing assembly 2 and the earth shovel assembly 4, the earth shovel assembly 4 is located between the separation assembly 5 and the seedling assembly 3, and on the frame 1 There is also a crushed soil component 6, which is located between the seedling cutting component 3 and the soil shoveling component 4, and the frame 1 is also provided with a peanut seedling for clamping and cooperating with the cutting seedlings. Component 3 cuts off the peanut seedling assembly 7, the seedling assembly 7 collects the peanut seedlings cut off by the cutting assembly 3 and discharges the collected peanut seedlings to one side of the frame 1, the frame 1 A screw conveyor f...

Embodiment 2

[0045] refer to Figure 1 to Figure 6 , in order to simplify the structure of the mowing assembly 2, so that the mowing assembly 2 has better performance, on the basis of the above embodiment: the mowing assembly 2 includes a mowing shaft 21, and the mowing shaft 21 is rotatably connected On the frame 1, there are two mower shafts 21, mower knives 22 are arranged on the mower shaft 21, and at least two groups of mowers are arranged on each mower shaft 21. Grass cutter group 22, each group of described grass cutter group 22 includes at least two blades 23 for mowing, a part of the blades 23 stretches into the soil, and the drive shaft 8 is driven by the first bevel gear mechanism 81. Describe mowing shaft 21. The blade 23 can be integrated with the mowing shaft 21 . The first bevel gear mechanism 81 is mainly used to change the transmission direction of the power. The specific structure of the first bevel gear is not limited. In the actual design, it is reasonably designed ac...

Embodiment 3

[0047] refer to Figure 1 to Figure 6 In order to simplify the structure of the seedling cutting assembly 3 so that the seedling cutting assembly 3 has better performance, on the basis of the above-mentioned embodiment: the seedling cutting assembly 3 includes a cutting shaft 31, and the cutting shaft 31 is rotatably connected On the frame 1, there are two seedling cutting shafts 31, two seedling cutting shafts 31 are provided with a seedling cutting knife 32, and the drive shaft 8 drives the seedling cutting shaft 8 through a second bevel gear mechanism 82. Seedling cutting shaft 31. Seedling cutter 32 can be integrated with seedling cutting shaft 31. Seedling cutting shaft 31 can be rotatably connected on the frame 1 by bearing.

[0048] The seedling cutting assembly 3 includes a seedling cutter 32 arranged on the mowing shaft 21 , and the seedling cutter 32 is located above the blade 23 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com