Heat dissipation silica gel sheet with embedded heat conduction groups

A technology of silica gel sheet and inner silicon, which is applied in the field of heat dissipation silica gel sheet with embedded heat conduction group, can solve the problems of poor heat transfer of heating elements, limited application range, poor heat dissipation effect, etc., achieve wide application range and improve heat conduction effect , Improve the effect of fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

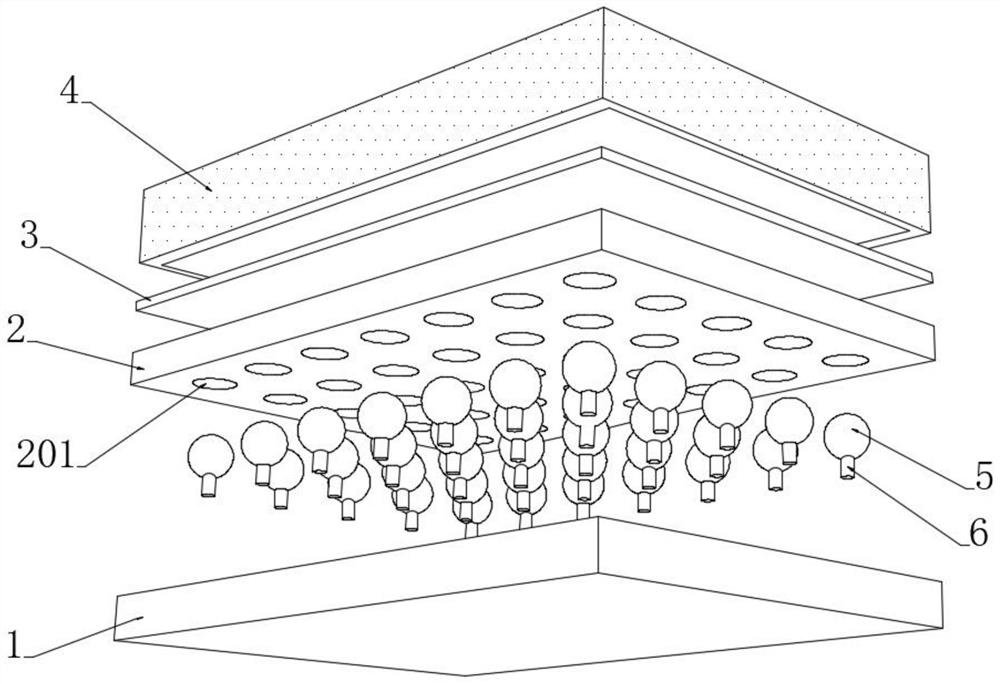

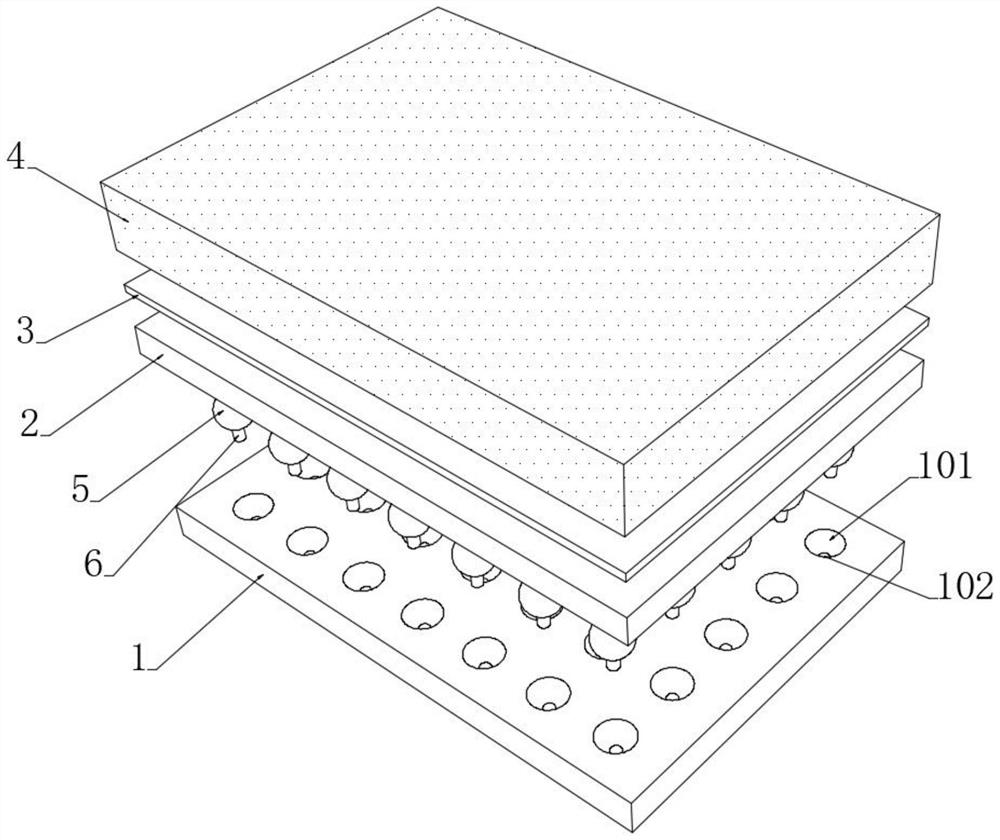

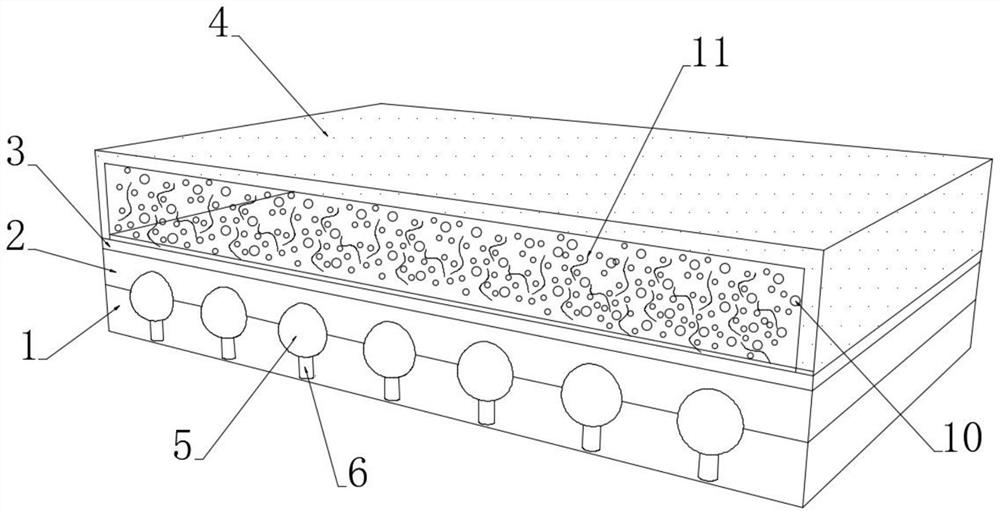

[0040] see Figure 1-3 , a heat dissipation silica gel sheet embedded with a heat conduction group, comprising an outer silica gel layer 1 for bonding to one end of a heat sink, an inner silica gel layer 2, a metal heat conduction layer 3 and a flexible connecting layer 4 are stacked on the outer silica gel layer 1, The flexible connecting layer 4 is attached to the side of the heating element. Both the outer silica gel layer 1 and the inner silica gel layer 2 are made of a mixture of thermally conductive silica gel and graphene particles. The mass ratio of thermally conductive silica gel to graphene particles is 4:1. The layer 1 and the inner silica gel layer 2 themselves have good thermal conductivity, and can transfer the heat generated by the heating element to one end of the radiator, and the heat is dissipated outward through the radiator.

[0041] see Figure 3-6 , between the outer silica gel layer 1 and the inner silica gel layer 2, a plurality of uniformly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com