Hydrophilic lubricating coating for the surface of a medical catheter

A medical catheter and hydrophilic technology, applied in the direction of catheters, coatings, etc., can solve the problems of uniform coating of unfavorable hydrophilic polymers, lower solubility, lower lubricity and wettability of medical catheters, etc., to achieve Improve the uniformity of spreading, improve fluidity, and have strong reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiments 1-18 provide a hydrophilic lubricating coating for the surface of a medical catheter, which will be described below by taking Embodiment 1 as an example.

[0032] The hydrophilic lubricating coating for the surface of the medical catheter provided by embodiment 1, its preparation steps are:

[0033] First mix 200g polyvinylpyrrolidone, 100g polyvinyl alcohol, 50g hydroxyethyl starch, 50g cross-linked polyacrylic acid resin, 400g solvent, stir evenly, then add 100g polyethyleneimine and 100g maleic anhydride grafted SEBS, mix, Stir evenly to obtain a hydrophilic lubricating coating for the surface of the medical catheter;

[0034] Wherein, the polyvinylpyrrolidone is PVP-K110, the number average molecular weight is 1.0993 million, purchased from Gobekie Company; the polyvinyl alcohol is PVA-124, the average degree of polymerization is 2400-2500, and the degree of alcoholysis is 98-99mol% , purchased from Kuraray, Japan;

[0035] The hydroxyethyl starch is h...

Embodiment 2-5

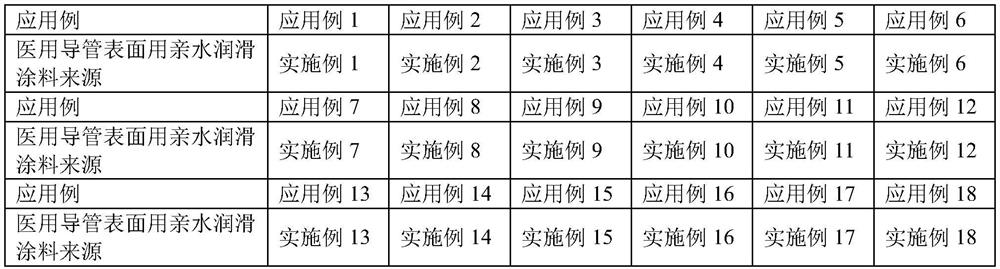

[0040] Examples 2-5 differ from Example 1 only in that the quality of the raw materials for the preparation of the hydrophilic lubricating coating for the surface of the medical catheter is different, see Table 1 for details.

[0041] Prepare raw materials Example 1 Example 2 Example 3 Example 4 Example 5 Polyvinylpyrrolidone 200g 400g 300g 300g 300g polyvinyl alcohol 100g 200g 150g 150g 150g Hydroxyethyl starch 50g 150g 100g 50g 100g Cross-linked polyacrylic resin 50g 150g 100g 50g 100g solvent 400g 600g 500g 500g 500g Polyethyleneimine 100g 200g 150g 150g 100g Maleic anhydride grafted SEBS 100g 200g 150g 150g 100g

Embodiment 6-8

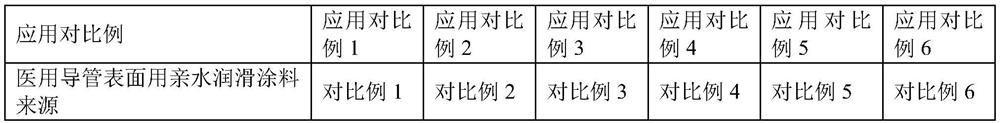

[0042] Examples 6-8 differ from Example 3 only in that the solvents are different, see Table 2 for details.

[0043] Example solvent Example 3 Water, isopropanol and triethylamine are mixed at a mass ratio of 5:1:0.01 Example 6 Water, isopropanol and triethylamine are mixed at a mass ratio of 8:1:0.02 Example 7 Water, isopropanol and triethylamine are mixed at a mass ratio of 6:1:0.015 Example 8 Water and isopropanol are mixed at a mass ratio of 5:1

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com