Zinc oxide dust removal device

A technology of dust removal device and zinc oxide, which is applied in the field of dust removal device and zinc oxide dust removal device, which can solve the problems of complex structure, inconvenient cleaning, and huge design redundancy, so as to improve the consistency of particle size, improve the quality of terminals, and obtain raw materials easily Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

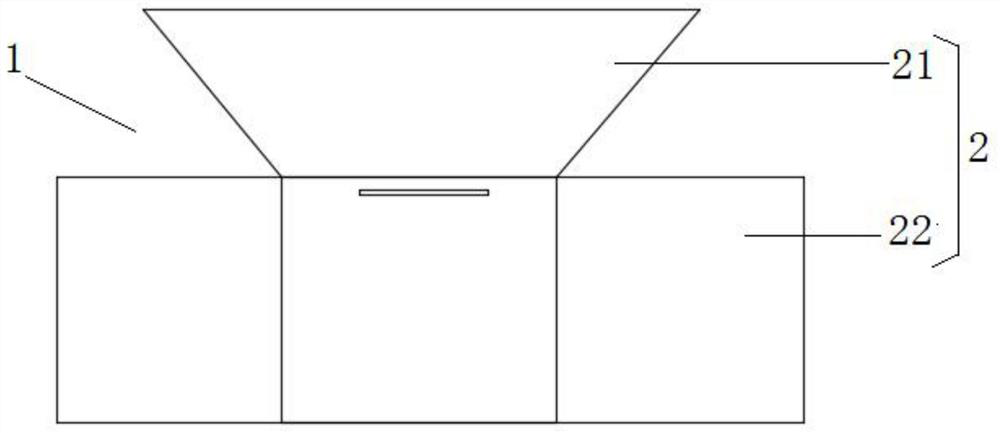

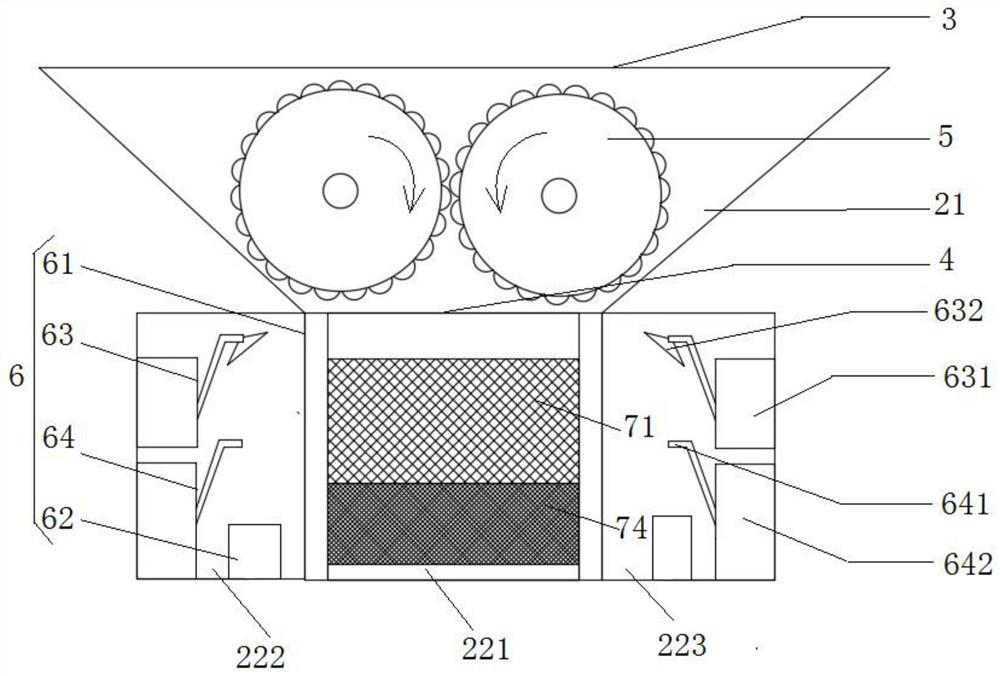

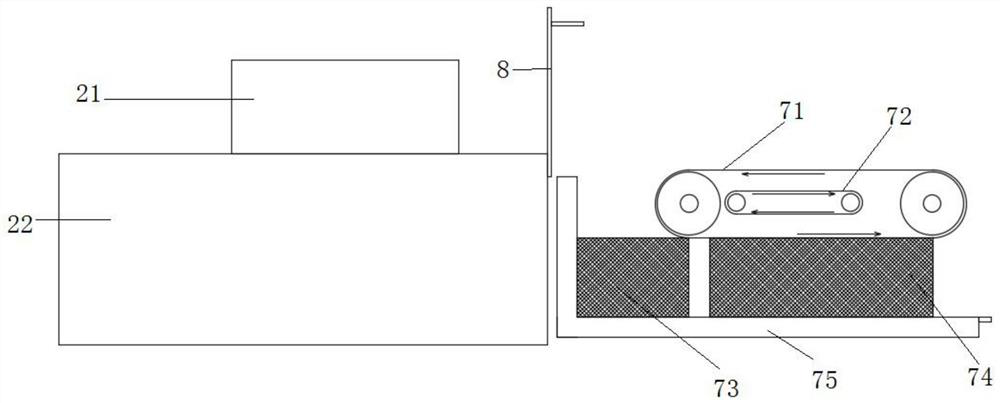

[0039] Such as Figure 1-7 As shown, this embodiment provides a zinc oxide dust removal device 1, which mainly includes a housing 2, a scrap assembly and a dust removal assembly. The housing 2 includes a feed chamber 21 and a dust removal chamber 22 connected to the bottom of the feed chamber 21. The top of the feed chamber 21 is provided with a monolith inlet 3, and the top of the dust removal chamber 22 is provided with a broken material that communicates with the feed chamber 21. import 4. The crushed material assembly is arranged in the feeding chamber 21 and includes crushing rollers 5, and the two crushing rollers 5 are arranged adjacent to each other and rotate in opposite directions for crushing the zinc oxide monolith. The dust removal assembly is detachably installed in the dust removal chamber 22, including the dust adsorption element 6 and the zinc oxide scrap screening device 7; the zinc oxide scrap screening device 7 mainly includes a sieve conveying mesh belt 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com